Block nano structure low-carbon steel and manufacturing method thereof

A nanostructure and low-carbon steel technology, applied in the direction of nanotechnology, can solve the problems of complex preparation process of nanomaterials, limited material size, difficult internal pores, etc., to achieve easy control and mass production, high tensile strength and fatigue The effect of extreme, uniform internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

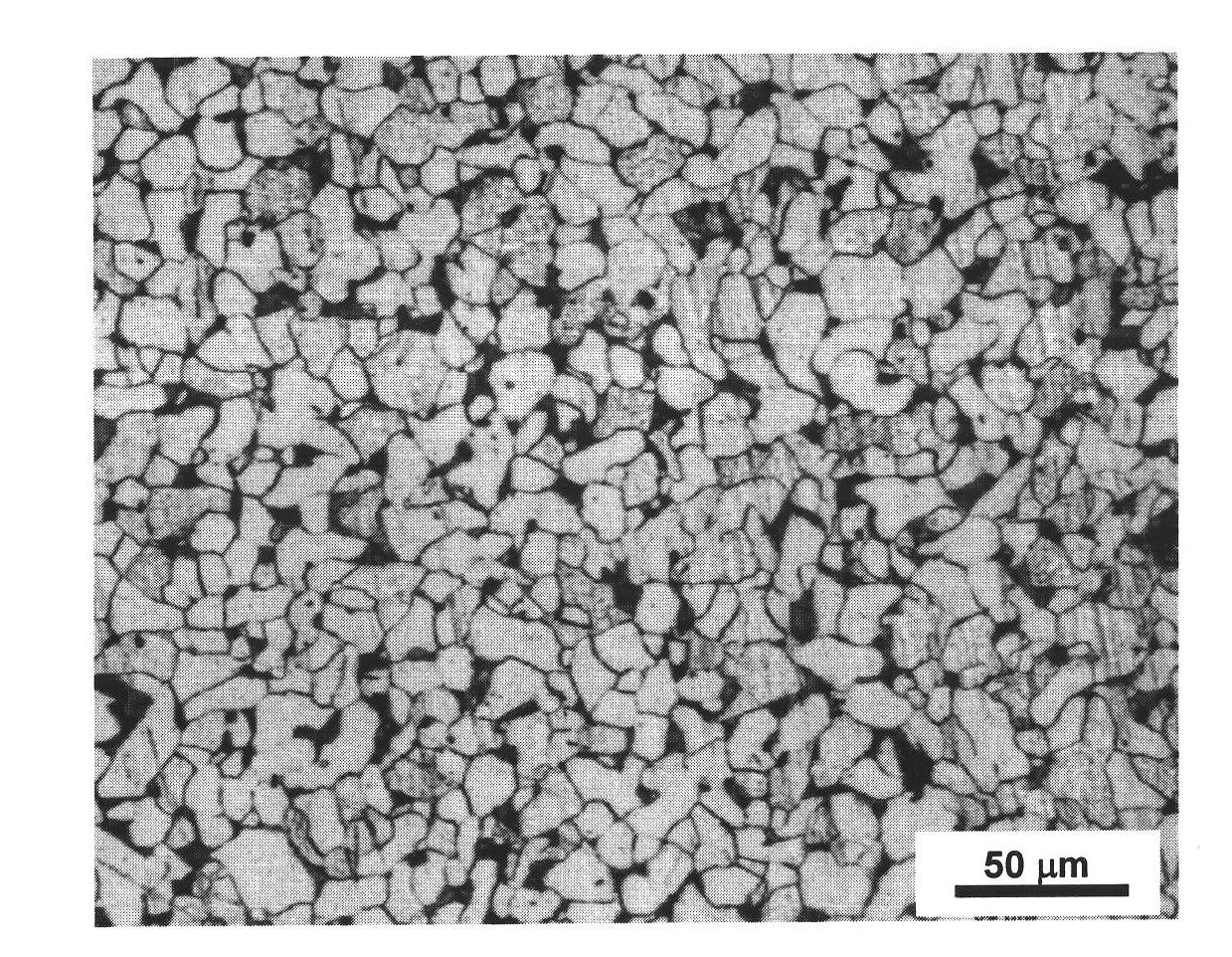

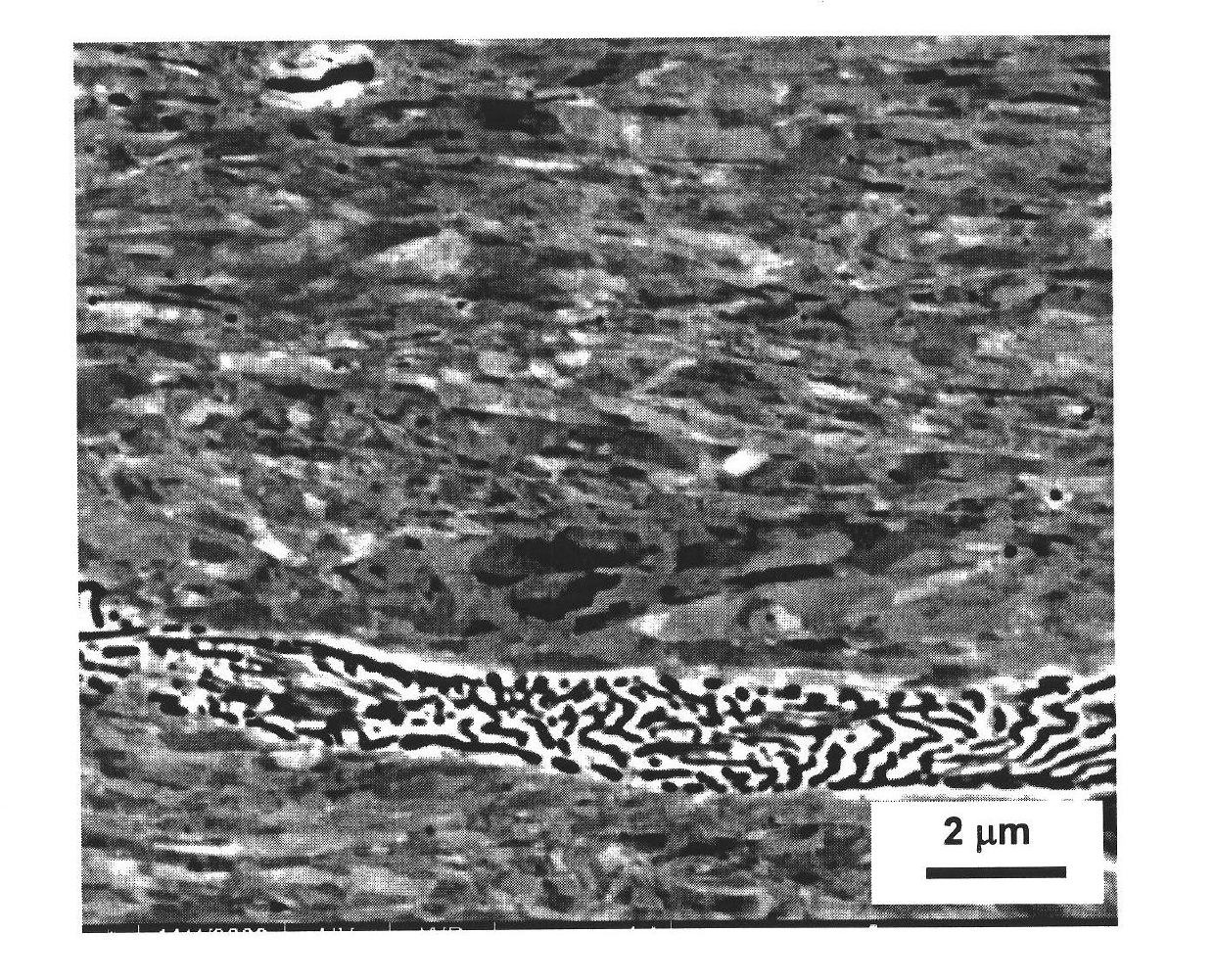

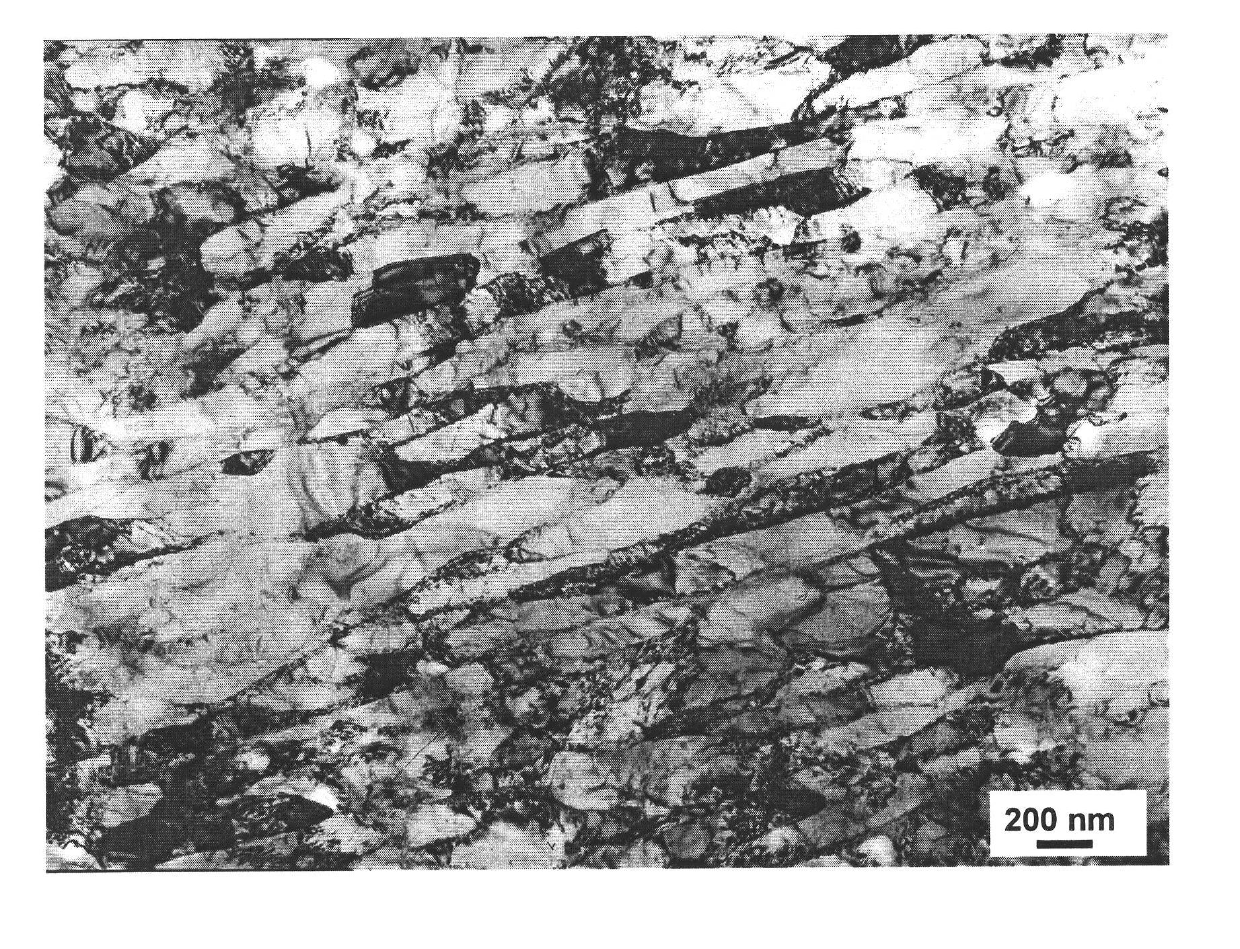

[0047] Sample size φ22mm×35mm. Perform multiple deformation treatments at room temperature, each deformation strain is about 0.1-0.2, and the cumulative strain is about 1.73. The sample size after treatment is φ52.7mm×6.5mm. like figure 2 , image 3 As shown, SEM-ECC (Scanning Electron Microscope Electron Channel Contrast) and TEM (Transmission Electron Microscope) cross-sectional observations show that the microstructure is lamellar ferrite grains and deformed pearlite. Obviously, after the above treatment, the ferrite grains become lamellar, and high-density dislocations are distributed inside. The average size of the ferrite grains in the minor axis direction is 200 nm. from Figure 4 It can be seen from the engineering stress-strain curve that its tensile strength is 976MPa and its elongation at break is 4.0%. from Figure 5 As can be seen from the typical fatigue life curve shown, the 50% survival rate fatigue limit is 270MPa, where the stress concentration factor...

Embodiment 2

[0049] Sample size φ10mm×17mm. Multiple deformation treatments were carried out at room temperature, each deformation strain was about 0.23, and the cumulative strain was about 2.1. The sample size after treatment is φ31.2mm×2mm. SEM-ECC and TEM section observations show that the microstructure is lamellar ferrite grains and deformed pearlite. Hardness test shows that its average hardness is Vickers hardness HV271. A tensile test at room temperature shows that its tensile strength is 1014MPa, and its elongation at break is 3.8%.

Embodiment 3

[0051] The size of the sample is φ15mm×20mm, and it is subjected to multiple deformation treatments at room temperature. The strain of each deformation is about 0.1-0.2, and the cumulative strain is about 1.4. The sample size after treatment is φ33.2mm×5.0mm. SEM-ECC and TEM section observations show that the microstructure is lamellar ferrite grains and deformed pearlite. Hardness test shows that its average hardness is Vickers hardness HV264. Tensile test at room temperature showed that the tensile strength was 978MPa and the elongation at break was 5.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com