Visual system used in particle trapping process of diesel engine

A technology for particle trapping and diesel engine, applied in the field of visualization system, can solve the problem of inability to observe the deposition process, and achieve the effect of convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

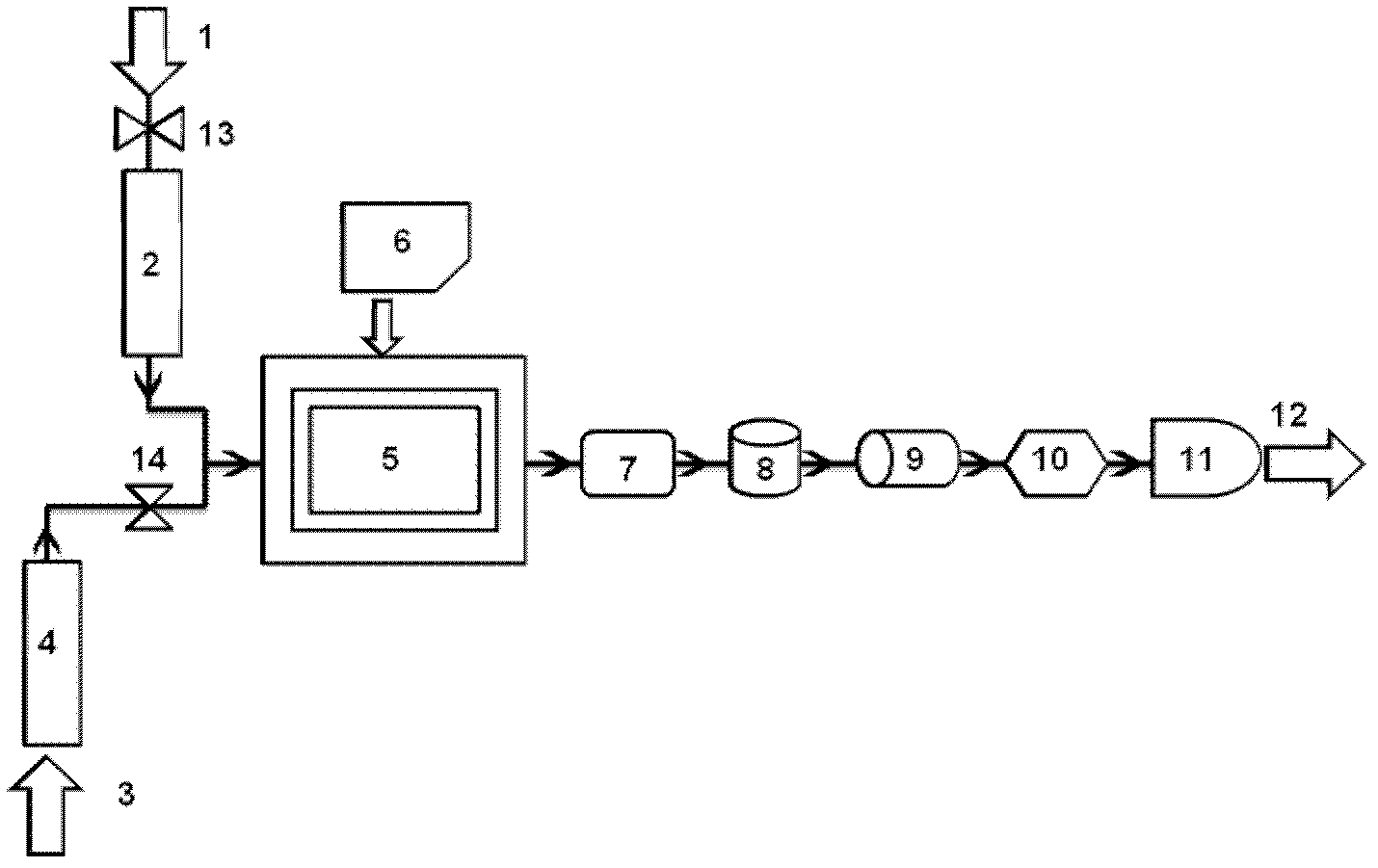

[0027] figure 1 Middle: 1. Air inlet; 2. (System) preheating heater; 3. Diesel engine exhaust gas inlet; 4. Exhaust gas sampling heating pipe; 5. (System) main section; 6. Visualization instrument; 7. Cooler; 8. Dryer; 9. Filter; 10. Mass flow meter; 11. Vacuum pump; 12. Evacuation port; 13. (System preheating heater branch valve) air inlet valve; 14. (Tail gas sampling heating pipe) valve.

[0028] figure 1 As shown, the present invention includes a visual instrument 6, the outlet of the preheating heater 2 used for introducing air is communicated with the air inlet of the main body section 5 through a pipeline, and the exhaust gas sampling heating pipe 4 used for introducing diesel engine exhaust is equipped with a valve 14 The pipeline of the main body section 5 communicates with the air inlet of the main body section 5, and the air outlet of the main body section 5 is connected to the cooler 7, the dryer 8, the filter 9 for separating particles in the gas, the mass flow m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com