Method using processing parameter to predict control indexes during tobacco processing procedures

A technology of processing parameters and processing procedures, which is applied in the field of processing parameter prediction and control indicators, can solve problems such as insufficient data application, and achieve the effect of thorough understanding and mastery, and timely warning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

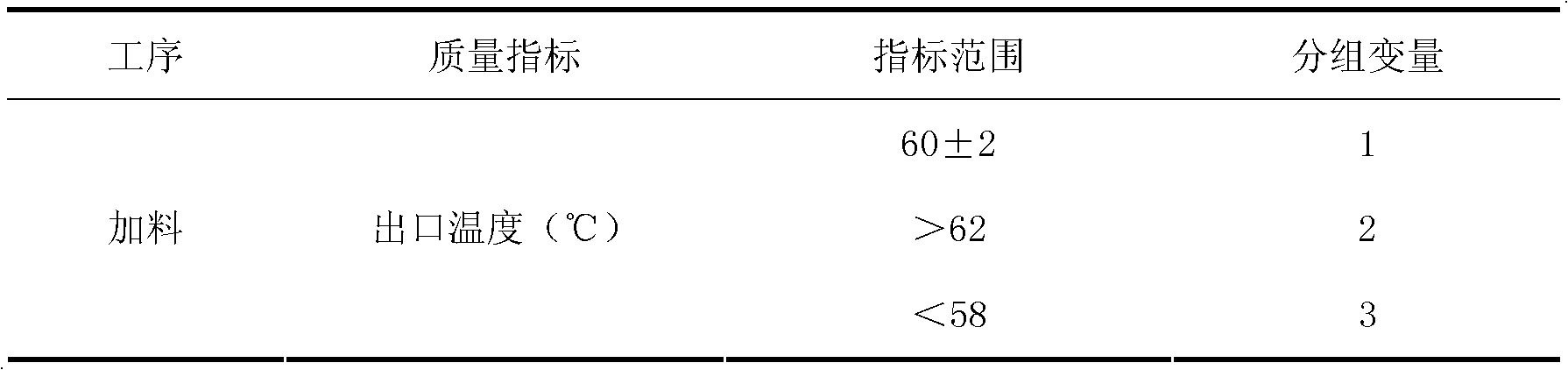

[0020] (1) Select the feeding process in the processing of Yunyan (purple), and collect the data of process parameters (instantaneous value of feeding, instantaneous value of return air temperature) and process index (outlet temperature) data of a certain batch. Take the control tolerance range and 3 times the sigma area as the discriminant rule, eliminate the wrong or special samples in the data, and match the process parameter data and process index data in chronological order, and take 5 consecutive points as a group , take the average value as the minimum research unit, and determine the grouping criteria based on the process index tolerance as shown in Table 1:

[0021] Table 1 Grouping criteria for quality indicators of feeding process

[0022]

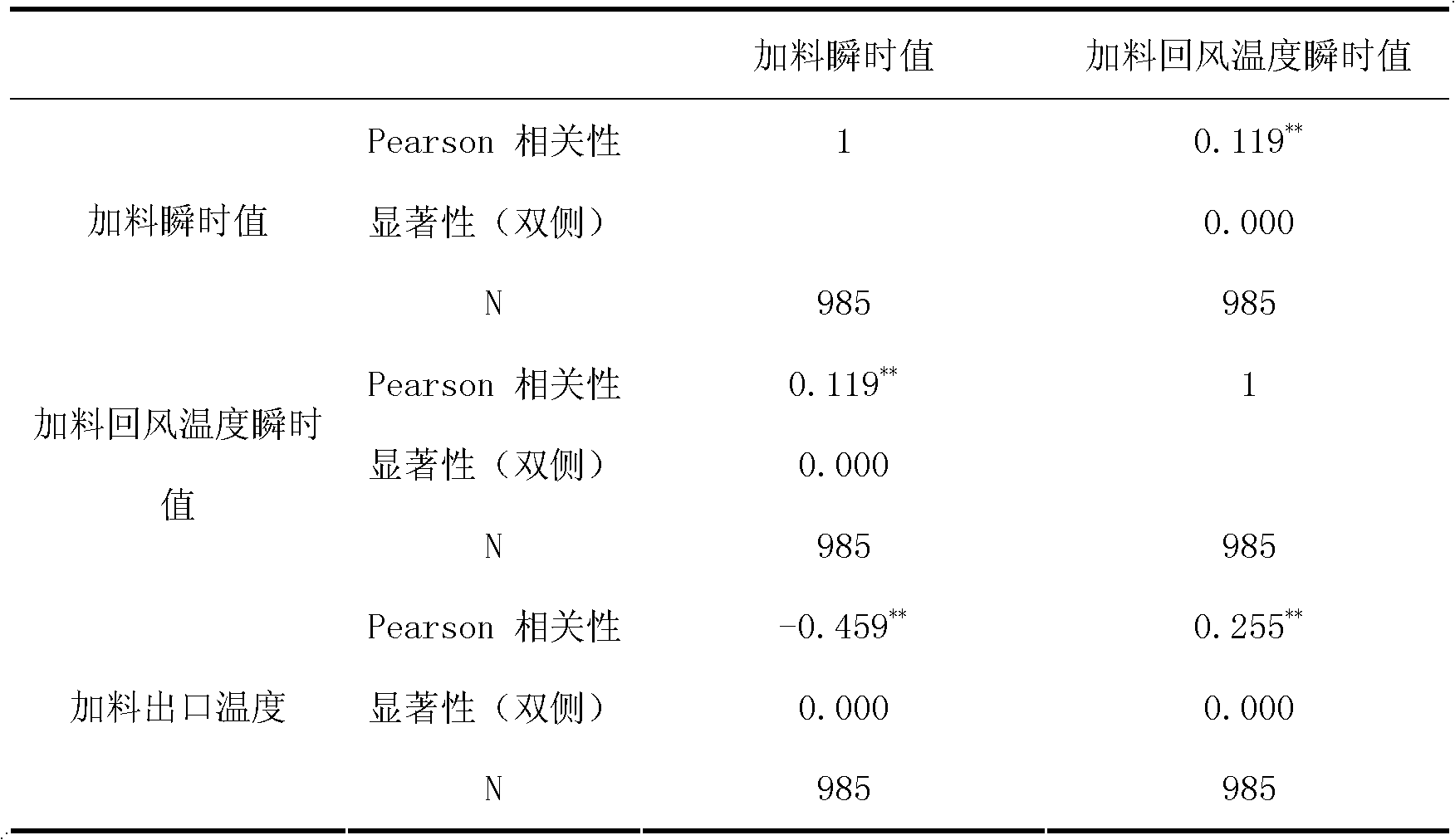

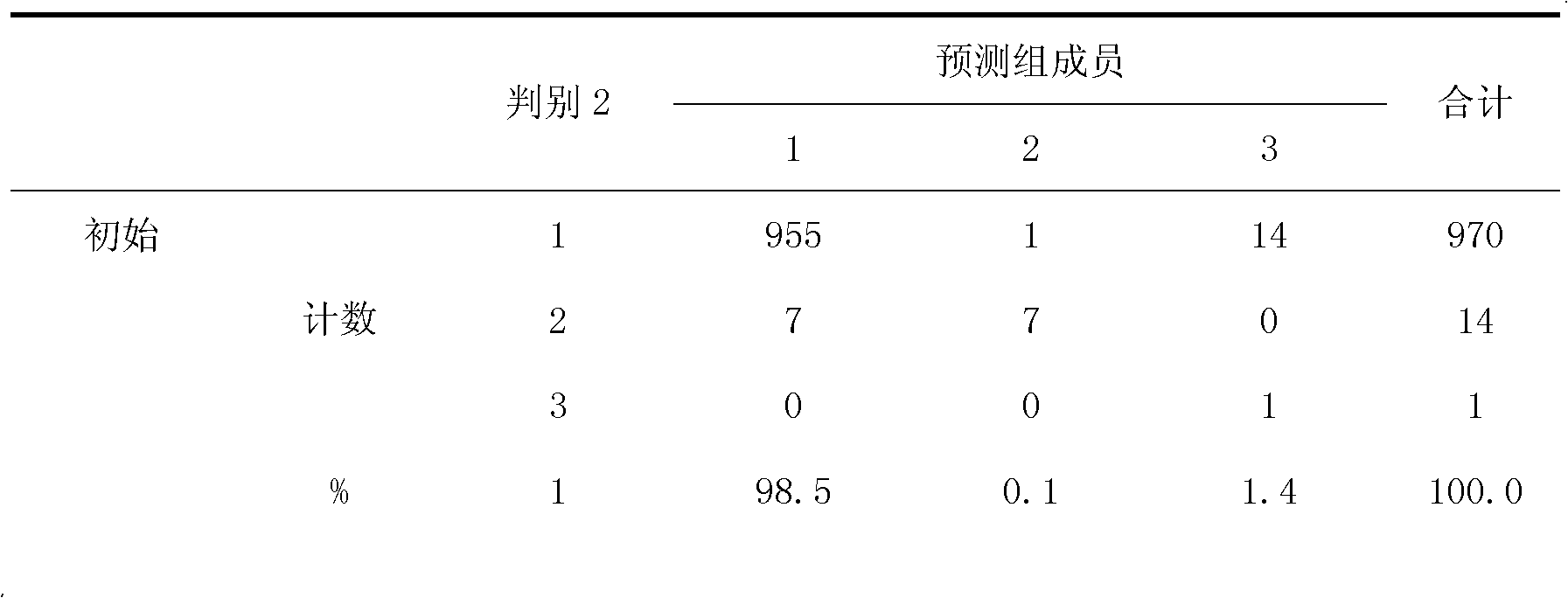

[0023] (2) Analyze and process the averaged data, and see Table 2 for the correlation analysis results of the processing parameters and quality indicators in the feeding process. It can be seen from Table 2 that the outlet t...

Embodiment 2

[0047] (1) Select the loose moisture regain process in the processing of Yunyan (purple), and collect the data of process parameters (instantaneous value of water addition, instantaneous value of return air temperature) and process indicators (moisture content at outlet) of three consecutive batches in the near future. Taking the control tolerance range and 3 times the sigma area as the judgment rule, eliminate the wrong or special samples in the data, and take 20 consecutive batches of process parameter data and process index data in a chronological order, and point-to-point The point is a group, and the average value is taken as the minimum research unit, and the grouping criteria are determined according to the tolerance of the process index of the plant, as shown in Table 5:

[0048]Table 5 Grouping Criteria for Quality Indexes of Loose Moisturizing Process

[0049]

[0050] (2) After analyzing and processing the averaged data, it can be obtained that the water content ...

Embodiment 3

[0074] (1) The drum drying process in the same Yunyan (purple) processing process, collect the process parameters (moisture content of incoming material, incoming material flow rate, cylinder wall temperature, return air temperature) data and process indicators of 10 consecutive batches recently (outlet temperature, moisture) data. Take the control tolerance range and 3 times sigma area as the judgment rule, eliminate the wrong or special samples in the data, and take 50 consecutive points as one in the process parameter data and process index data in the way of batch-to-batch and point-to-point The average value of the group is taken as the smallest research unit, and the grouping criteria are determined according to the tolerance of the process index of the plant, as shown in Table 7

[0075] Table 7 Grouping criteria of silk drying process quality indicators

[0076]

[0077]

[0078] (2) Analyzing and processing the averaged data, it can be obtained that the moistur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com