Method for manufacturing metal oxide semiconductor (MOS) tube

A technology of semiconductor tubes and manufacturing methods, which is applied in the field of metal oxide semiconductor tubes, and can solve the problems of uneven saturation current of MOS tubes, hindering the etching of ONO sidewall layers, and large differences in the characteristic dimensions of ONO sidewall layers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution, and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

[0034] The present invention has been described in detail using schematic diagrams. When describing the embodiments of the present invention in detail, for the convenience of explanation, the schematic diagram showing the structure will not be partially enlarged according to the general scale, which should not be used as a limitation of the present invention. In addition, in actual production In , the three-dimensional space dimensions of length, width and depth should be included.

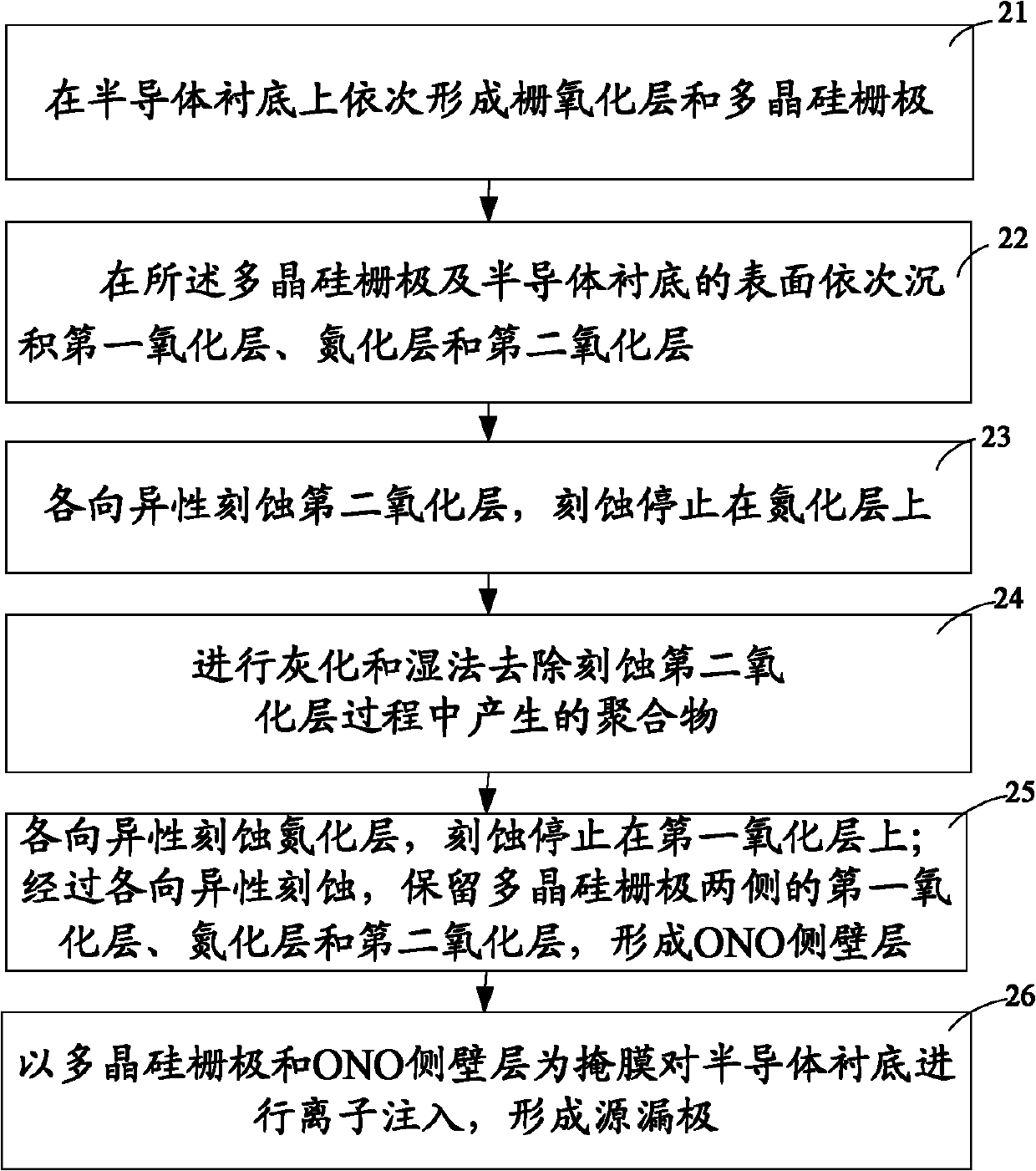

[0035] The manufacturing method of MOS tube of the present invention comprises the following steps, and the schematic flow chart is as figure 2 shown.

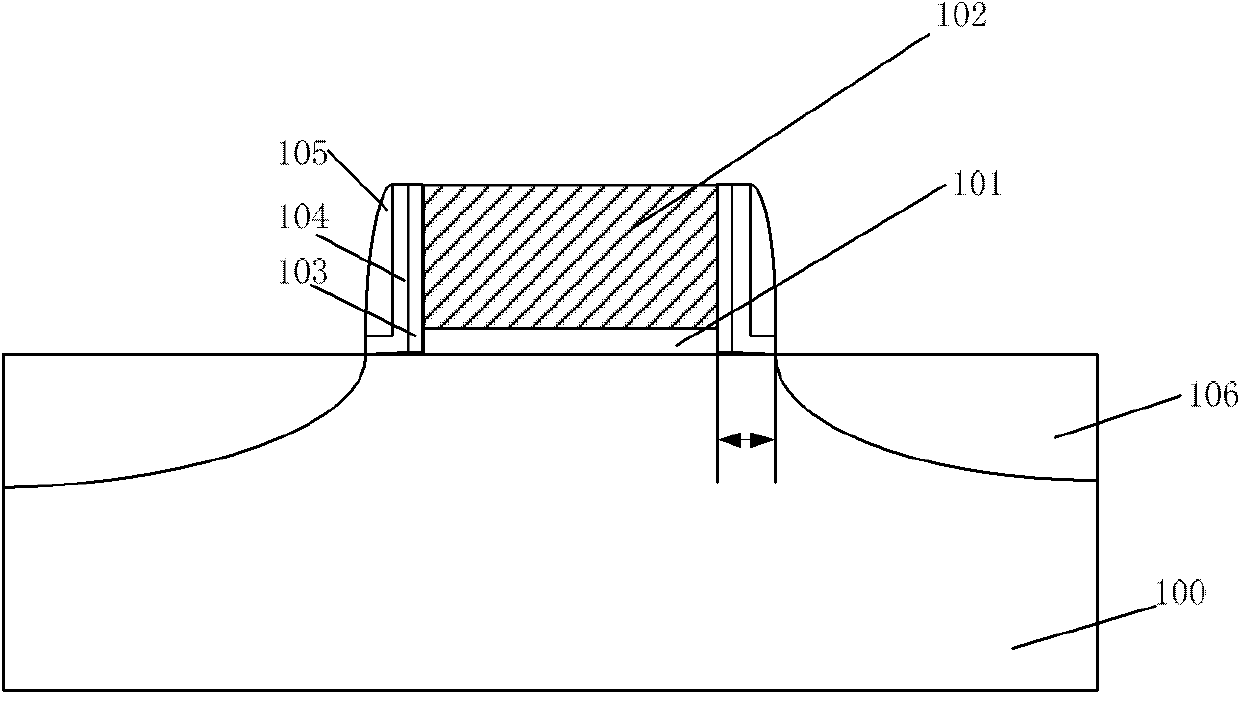

[0036] Step 21, sequentially forming a gate oxide layer 101 and a polysilicon gate 102 on the semiconductor substrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap