Feedforward automatic gain control circuit working in extremely low voltage current mode

A technology of automatic gain control and power supply voltage, applied in the direction of gain control, amplification control, electrical components, etc., can solve the problems of large power consumption, complex compensation circuit, low signal processing accuracy, etc., achieve low power consumption and solve continuity and the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

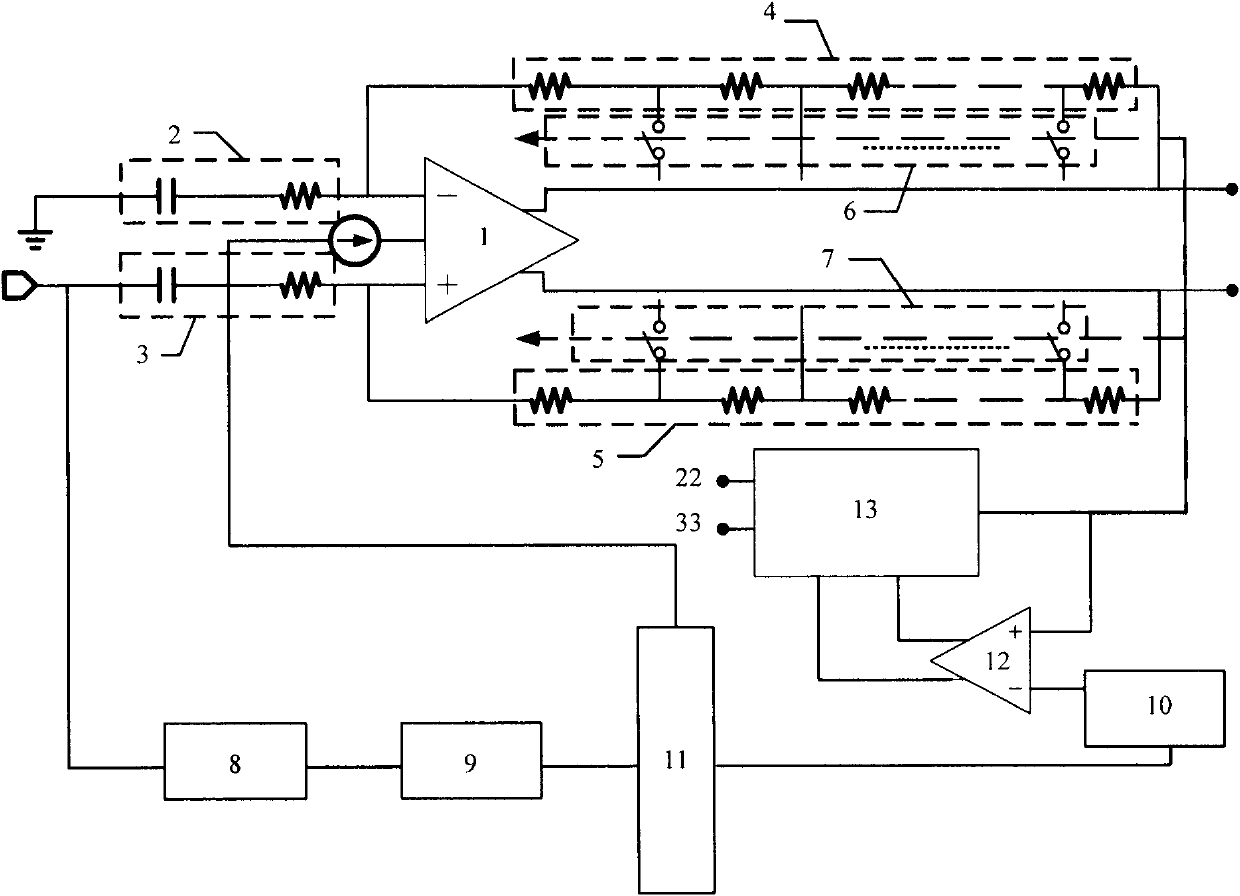

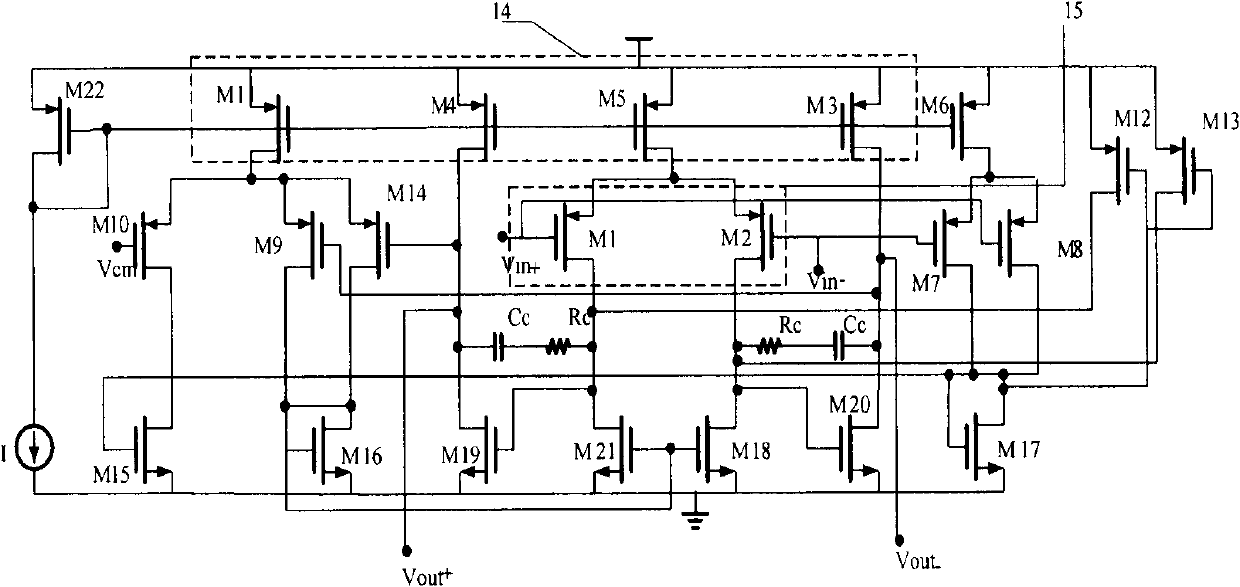

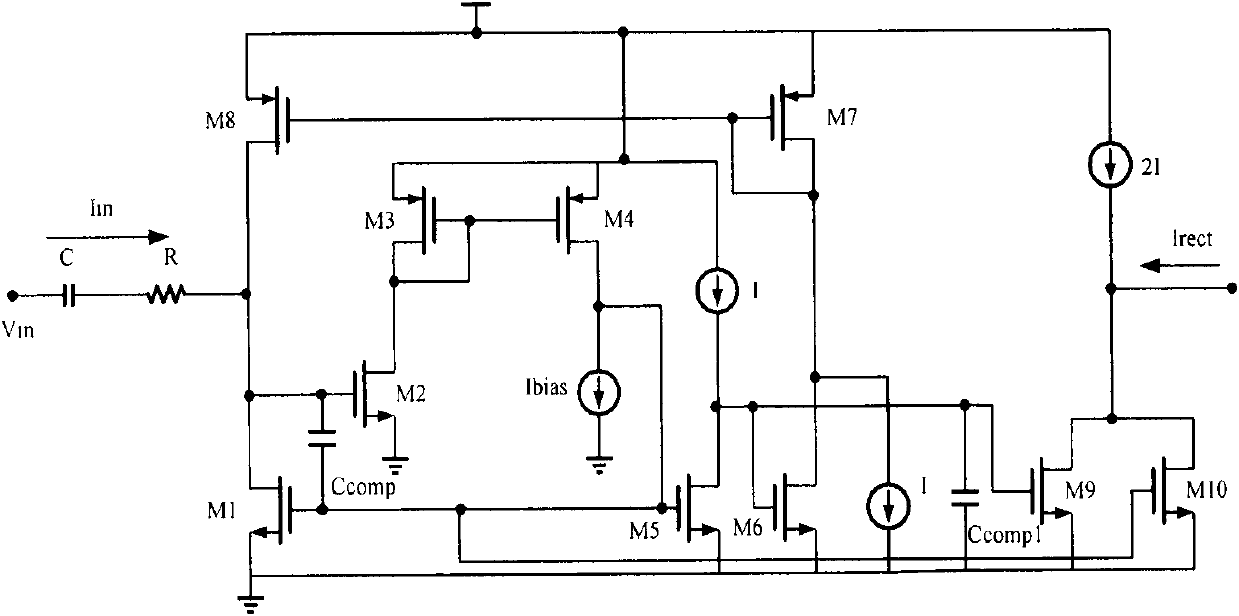

[0037] The present invention provides a current mode feed-forward automatic gain control circuit that works on extremely low power supply voltage, and effectively solves the existing problems in the prior art by adopting a circuit module that works on low power supply voltage, current mode feedforward and digital circuit control. non-linear problem.

[0038] In the present invention, capacitive resistance devices 2 and 3 perform high-pass on the microphone DC signal, filter the microphone DC signal, and read out the weak signal of the microphone by the fully differential operational amplifier circuit 1; at the same time, the envelope detection circuit composed of the rectifier 8 and the filter 9 detects The energy of the weak microphone signal, the digital controller 11 processes the energy to obtain a digital control signal, the digital reference table 10 finds the corresponding gain control code according to the digital control signal, applies it to the digital comparator 12,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com