Luminescent element, producing method thereof and luminescence method using the same

A technology of light-emitting element and manufacturing method, applied in the directions of light-emitting materials, electrical components, chemical instruments and methods, etc., can solve the problems of limiting the application of field emission devices and low luminous efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

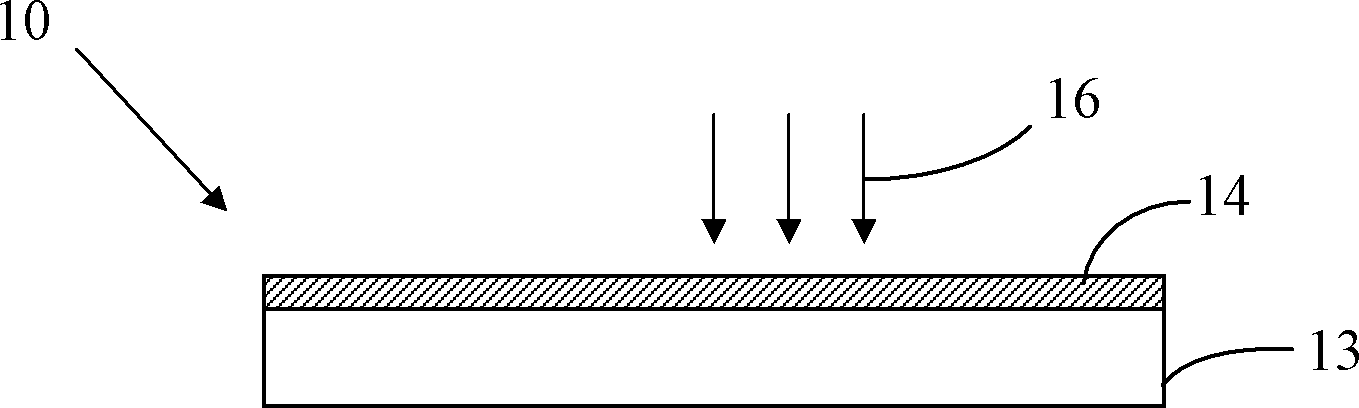

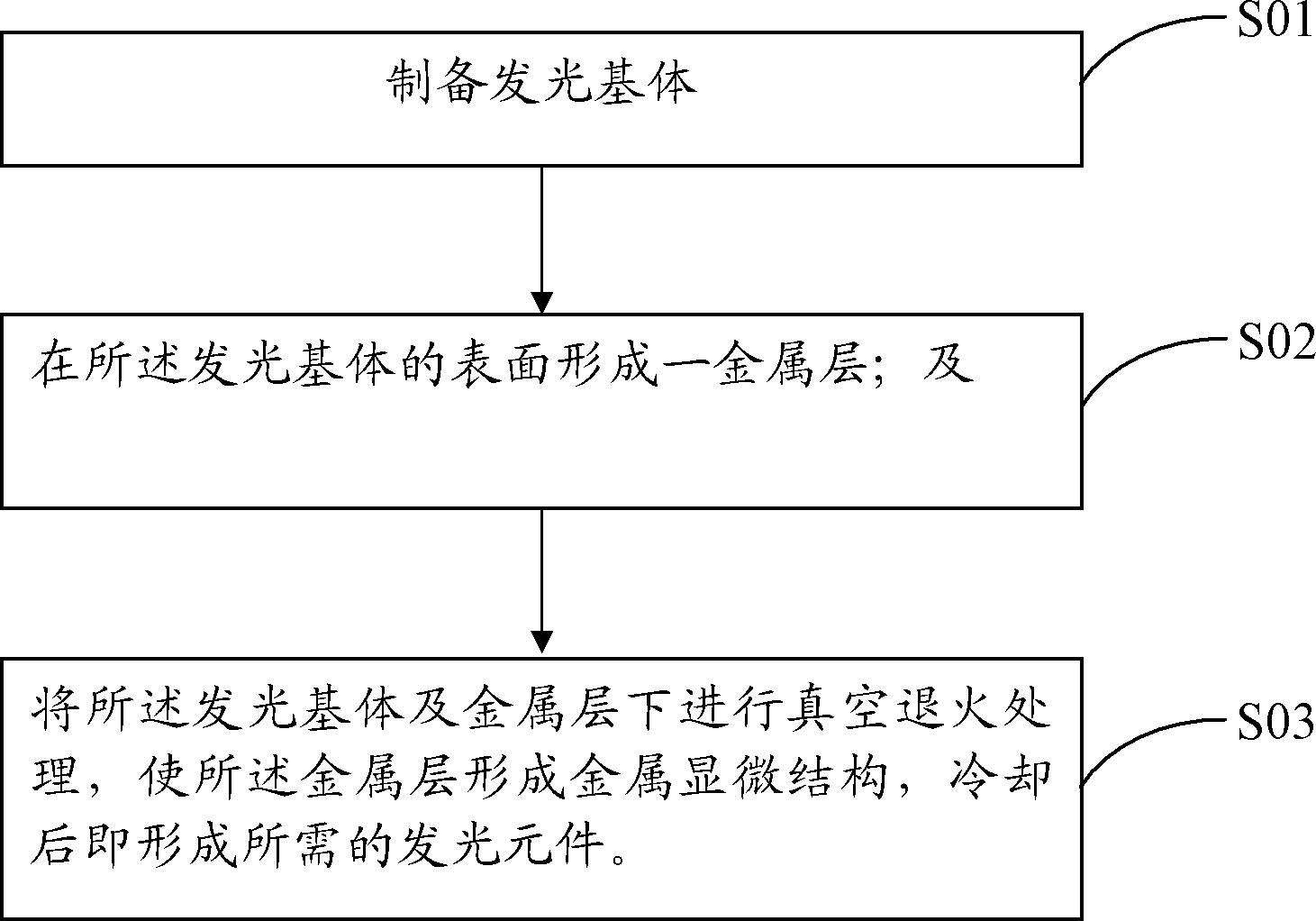

[0031] In step S01, corresponding to the above-described two structures of the light-emitting substrate 13: the first one is doped with Y 3 Al x Ga 5-x o 12 : Luminescent glass of Tb luminescent material, the second is Y 3 Al x Ga 5-x o 12 : Tb luminescent thin film is formed on the substrate. The preparation method of the first light-emitting matrix 13 includes the following steps: Y 3 Al x Ga 5-x o 12 : Tb luminescent material is mixed with glass powder, then melted at a temperature of 1000-1300 ° C, cooled to room temperature, and obtained doped with Y 3 Al x Ga 5-x o 12 : Luminescent glass of Tb luminescent material, wherein the molar fraction of the glass powder composition and its components is 20Na 2O-20BaO-30B 2 o 3 -30SiO 2 . Among them, Y 3 al x Ga 5-x o 12 : Tb luminescent material is also a powder, which is mixed with glass powder in a mass ratio of 1:19 to 7:13. After mixing, Y 3 al x Ga 5-x o 12 : The Tb luminescent material accounts for...

Embodiment 1

[0043] Will Y 3 (Al, Ga) 5 o 12 : Tb fluorescent powder and glass powder (the molar fraction of the composition and components is 20Na 2 O-20BaO-30B 2 o 3 -30SiO 2 ) is mixed and melted according to the mass ratio of 1:4 to obtain a compound doped with Y 3 (Al, Ga) 5 o 12 : Luminescent glass of Tb luminescent material. Then use magnetron sputtering equipment to deposit a metal silver layer with a thickness of 2nm on the surface of the luminescent glass, and then place it in a vacuum of less than 1×10 -3 Under a vacuum environment of Pa, annealing was performed at a temperature of 300° C. for half an hour, and then cooled to room temperature to obtain the light-emitting element of this embodiment.

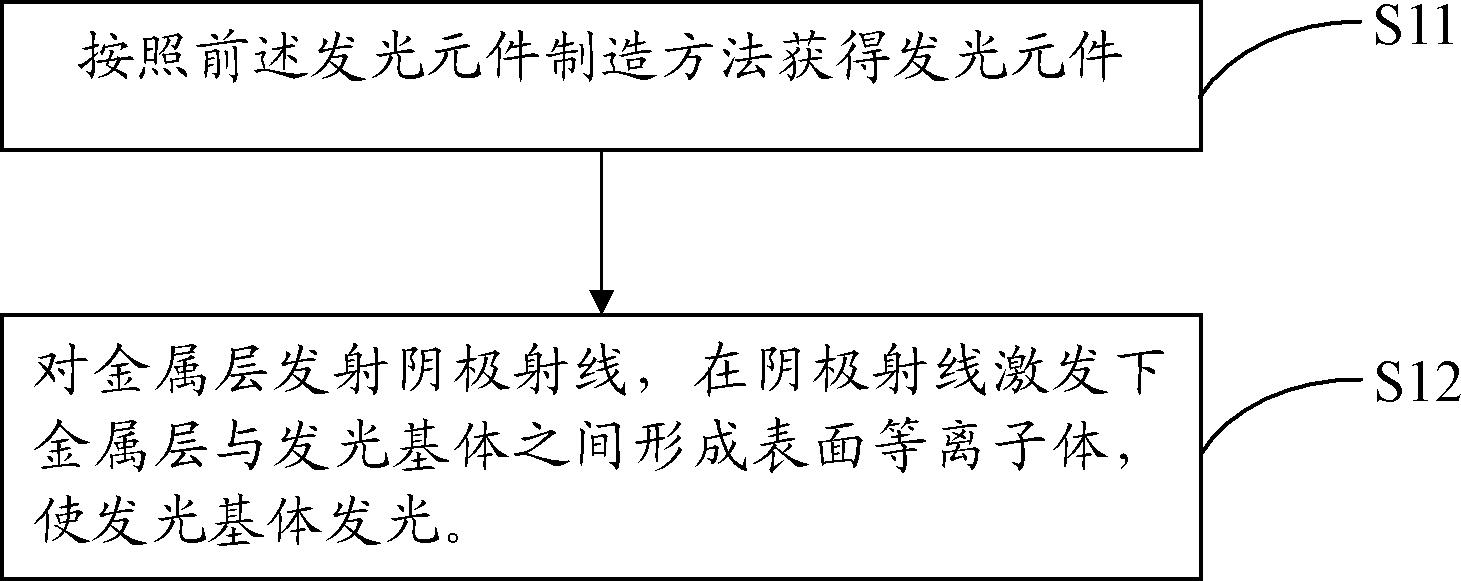

[0044] Spectrum testing is carried out on the light-emitting element prepared above, and the cathode ray generated by the electron gun is used to bombard the light-emitting element. The electron beam first penetrates the metal layer and then excites the doped Y 3 (Al, Ga) ...

Embodiment 2

[0047] Will Y 3 al 5 o 12 : Tb fluorescent powder and glass powder (the molar fraction of the composition and components is 20Na 2 O-20BaO-30B 2 o 3 -30SiO 2 ) is mixed and melted according to the mass ratio of 1:19 to obtain a compound doped with Y 3 al 5 o 12 : Luminescent glass of Tb luminescent material. Then use magnetron sputtering equipment to deposit a metal gold layer with a thickness of 0.5nm on the surface of the luminescent glass, and then place it in a vacuum of less than 1×10 -3 In a vacuum environment of Pa, annealing was performed at a temperature of 200° C. for 1 hour, and then cooled to room temperature to obtain the light-emitting element of this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com