Preparation method of zirconium dioxide false tooth

A zirconium dioxide and denture technology, applied in the field of zirconia denture preparation, can solve the problems of insufficient product strength, complicated procedures, poor preparation, etc., and achieve the effects of simplifying the procedure, changing the manufacturing process, and improving the quality of dentures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

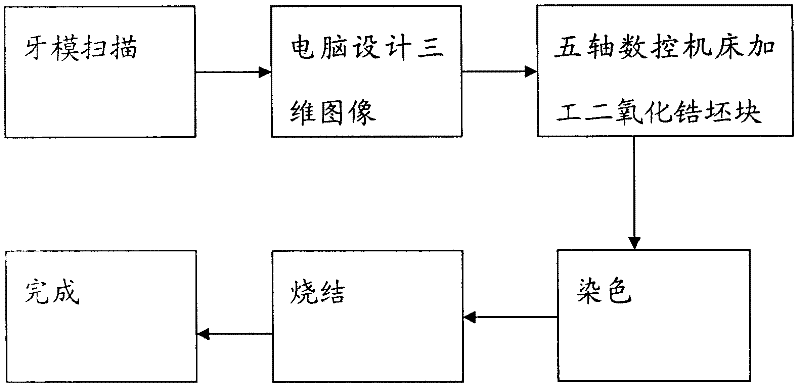

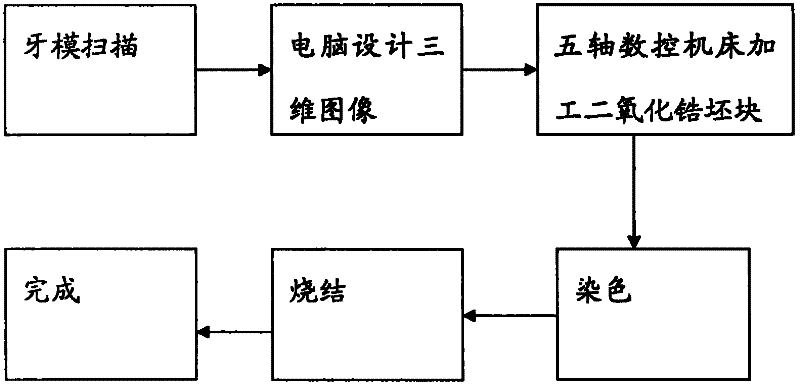

[0022] figure 1 It is the process flow chart of making zirconium dioxide of the present invention, as figure 1 As shown, the preparation process of the present invention is as follows: use a three-dimensional scanner to scan the dental model to form a virtual dental model image, then use a computer to design and restore the denture on the virtual image, and after the design is completed, transmit the data to a five-axis linkage CNC machine tool , after the zirconia block is processed by CNC machine tools, it is soaked and dyed, and then sintered to complete the production.

[0023] More detailed preparation process for making zirconia dentures:

[0024] 1. Preparation before scanning

[0025] Placing abutments on clay: Secure the abutments without shaking during scanning.

[0026] 2. Dental model scanning

[0027] Put the abutment to be scanned into the 3shape D700 scanner, open the 3shape dental manager client design software in the computer, and select the corresponding ...

Embodiment 2

[0047] 1. Preparation before scanning

[0048] Placing abutments on clay: Secure the abutments without shaking during scanning.

[0049] 2. Dental model scanning

[0050] Put the abutment to be scanned into the 3shape D700 scanner, open the 3shape dental manager client design software in the computer, and select the corresponding material according to the design sheet in the design software interface: zirconia, tooth position, type: inner crown / Full form, and then click the scan button to scan. The resulting image after scanning is in DCM format.

[0051] 3. Computer 3D graphics (design)

[0052] After scanning, open the design button in the design software to design. The main content of the design is to:

[0053] Inner crown: occlusal degree, adjacency is 1.5MM, thickness of crown is 0.55MM, space required for upper porcelain, strength is 1200MPA, beautiful.

[0054] Full-shaped crown: occlusal degree, adjacency, crown thickness 0.55MM, strength 1200MPA, beautiful.

...

Embodiment 3

[0070] 1. Preparation before scanning

[0071] Placing abutments on clay: Secure the abutments without shaking during scanning.

[0072] 2. Dental model scanning

[0073] Put the abutment to be scanned into the 3shape D700 scanner, open the 3shape dental manager client design software in the computer, and select the corresponding material according to the design sheet in the design software interface: zirconia, tooth position, type: inner crown / Full form, and then click the scan button to scan. The resulting image after scanning is in DCM format.

[0074] 3. Computer 3D graphics (design)

[0075] After scanning, open the design button in the design software to design. The main content of the design is to:

[0076] Inner crown: occlusal degree, adjacency is 2MM, crown thickness is 0.5MM, required porcelain space, strength is 1200MPA, beautiful.

[0077] Full-shaped crown: occlusal degree, adjacency, crown thickness 0.5MM, strength 1200MPA, beautiful.

[0078] After the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com