Preparation methods of Chuanxiongchatiao granule extracts and preparations thereof

The technology of preparation and extract of Chuanxiong tea is applied in the preparation of granules of Chuanxiong tea. In the preparation process, the preparation of Chuanxiong tea is in the field of extracts obtained by post-processing after extraction of medicinal materials, which can solve the problem of low concentration of material liquid and concentration of High temperature, product damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0096] Preparation Example 1: Preparation of extracts excluding volatile oils

[0097] Composition of raw materials:

[0098] 120 parts by weight of Rhizoma Chuanxiong, 60 parts by weight of Angelica dahurica,

[0099] Notopterygium 60 parts by weight, licorice 60 parts by weight,

[0100] Windproof 45 parts by weight, Asarum 30 parts by weight,

[0101] Mint 240 parts by weight, Schizonepeta 120 parts by weight.

[0102] Preparation method: (1) Take Rhizoma Chuanxiong, Angelica dahurica, Notopterygium, Asarum, Fangfeng, Licorice, add water to decoct, filter the decoction, and reserve the medicinal liquid; (2) Extract volatile oil from mint and Schizonepeta, set aside; filter the aqueous solution, The filtrate is combined with the medicinal solution obtained in step (1); (3) the combined medicinal solution obtained in step (2) is filtered through membrane nanofiltration (after the nanofiltration is completed, the nanofiltration membrane is cleaned with a cleaning agent), ...

preparation example 2

[0104] Preparation Example 2: Preparation of extracts excluding volatile oils

[0105] Composition of raw materials:

[0106] 120 parts by weight of Rhizoma Chuanxiong, 45 parts by weight of Angelica dahurica,

[0107] Notopterygium 45 parts by weight, licorice 75 parts by weight,

[0108] Windproof 33 parts by weight, Asarum 38 parts by weight,

[0109] Mint 300 parts by weight, Nepeta 90 parts by weight.

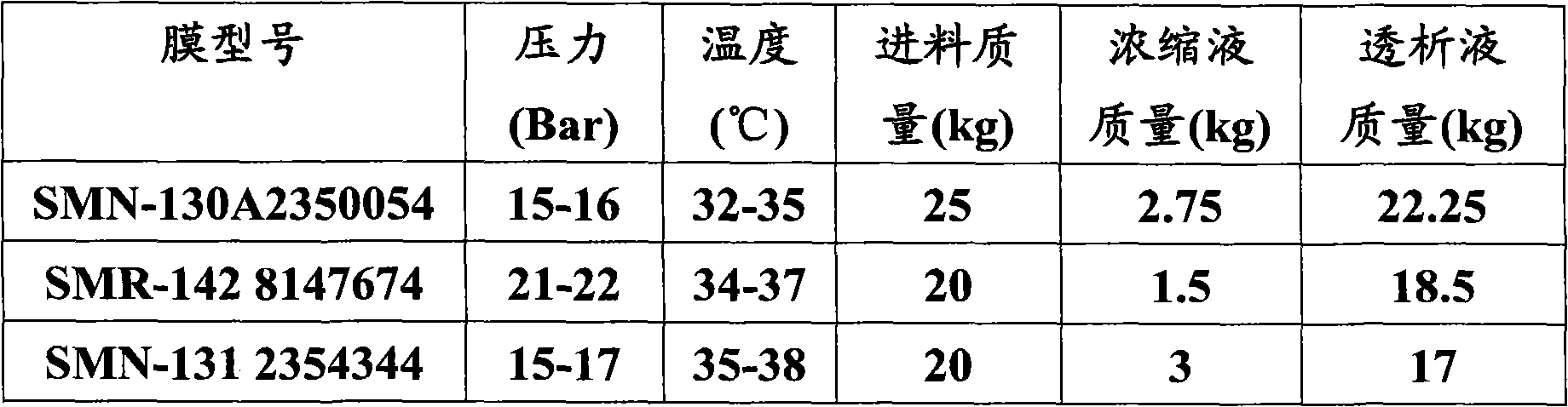

[0110] Preparation method: basically the same as Preparation Example 1, the difference is: in step (1), decoct in water twice, decoct in water for 1.5 hours with 6 times the amount of materials used for the first time, and decoct with 6 times the amount of materials used for the second time Fry for 1.5 hours; use organic membrane SMN-130A2350054 in step (3), filter temperature 35 ℃, filter pressure 18bar, nanofiltration concentrated solution relative density is 1.18 (36 ℃), membrane cleaning agent is 1% sodium polyphosphate.

preparation example 3

[0111] Preparation Example 3: Preparation of extracts excluding volatile oils

[0112] Composition of raw materials:

[0113] 120 parts by weight of Rhizoma Chuanxiong, 75 parts by weight of Angelica dahurica,

[0114] Notopterygium 75 parts by weight, licorice 45 parts by weight,

[0115] Windproof 56 parts by weight, Asarum 22 parts by weight,

[0116] 180 parts by weight of Peppermint, 150 parts by weight of Schizonepeta.

[0117] Preparation method: basically the same as Preparation Example 1, the difference is: in step (1), decoct in water once, and use 10 times the amount of medicinal materials to decoct in water for 3 hours; in step (3), use organic film SMN-130A2350054, The filtration temperature is 37° C., the filtration pressure is 16 bar, the relative density of the nanofiltration concentrate is 1.28 (36° C.), and the membrane cleaning agent is 1% sodium polyphosphate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com