Mixed butyraldehyde separation device and application of packed towers

A technology of separation device and packed tower, which is applied in the separation/purification of carbonyl compounds, distillation separation, separation methods, etc., to achieve the effects of high separation efficiency, reduced energy consumption, and low space occupation in the tower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

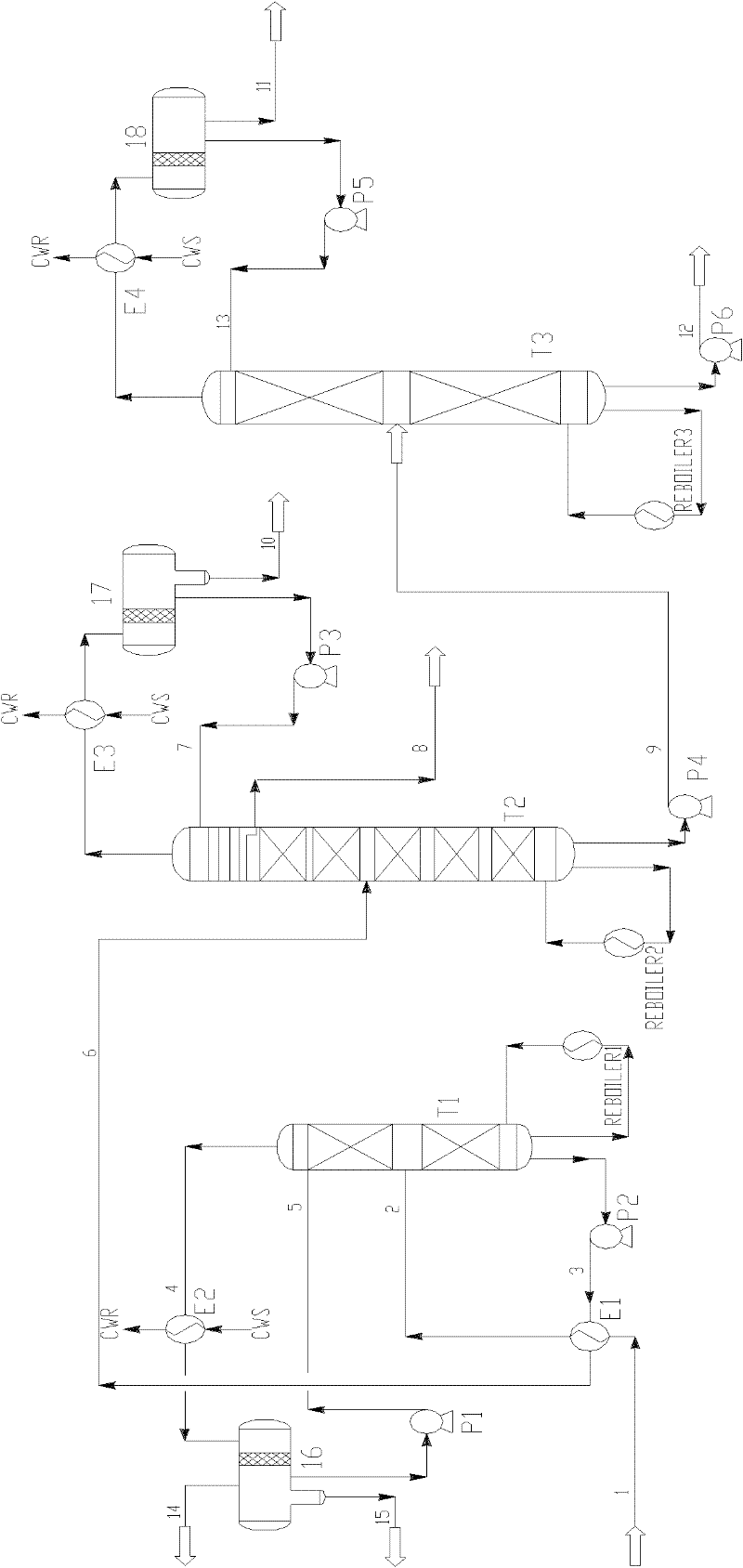

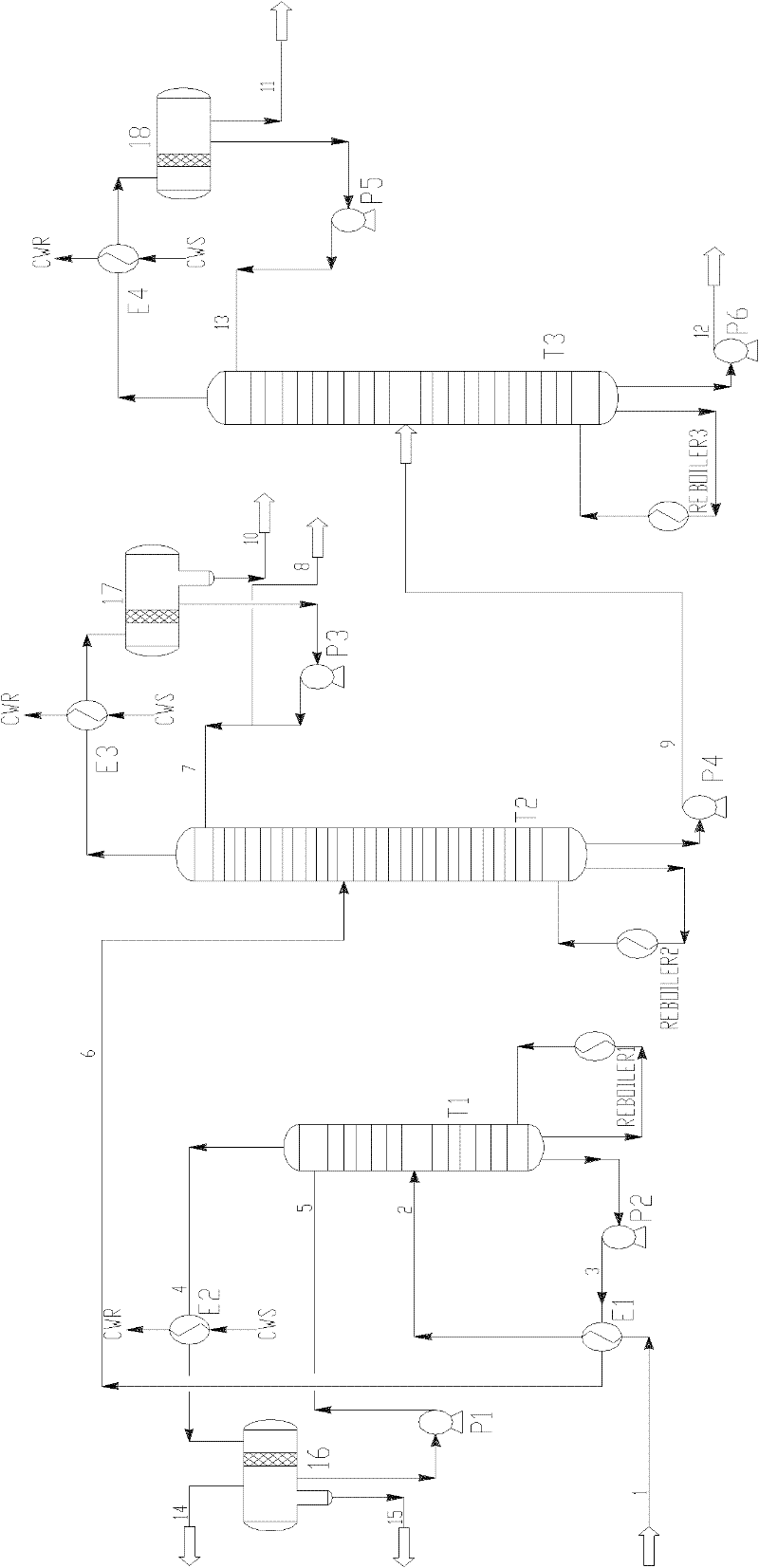

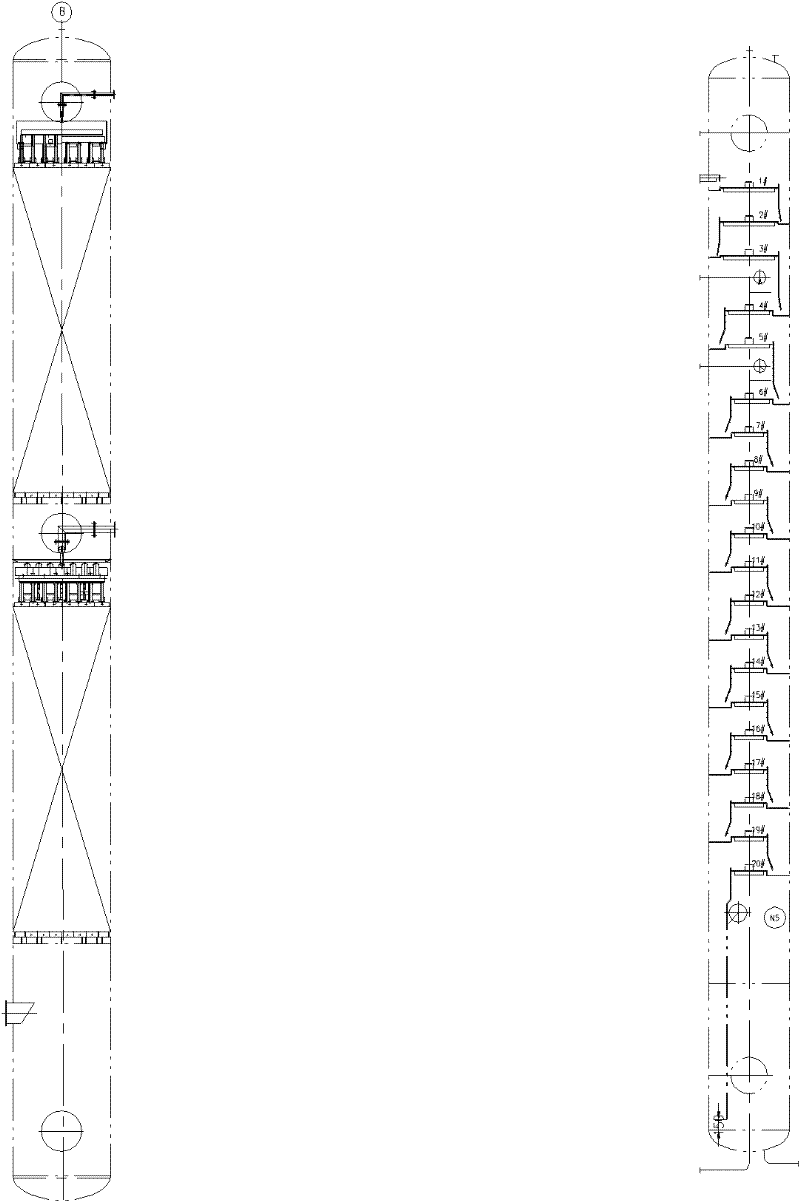

[0030] The mixed butyraldehyde separation device is composed of a stabilizing tower T1, an isomer tower T2, and a n-butyraldehyde tower T3. Wherein the mixed butyraldehyde 1 that reaction generates enters the middle part of stabilizing tower T1 through the pipeline, and the mixed butyraldehyde liquid 3 is produced at the bottom of the tower, and the tower top material 4 enters the tower top condenser E2 through the pipeline, and the air phase 13 enters the fuel gas main pipe, and the liquid phase 5 Return to the top of the stable tower T1 through the reflux pump P1. The mixed butyraldehyde liquid 3 is preheated by the heat exchanger E1 and fed into the stabilization tower T1, and then enters the middle part of the isomer tower T2 through the pipeline. P4 enters the middle part of the n-butyraldehyde tower T3, and after the gas phase at the top of the tower is condensed by the condenser E4, a part of the liquid phase is pumped to the top of the T3 tower through the reflux pump ...

Embodiment 2

[0034] The mixed butyraldehyde separation device is composed of a stabilizing tower T1, an isomer tower T2, and a n-butyraldehyde tower T3. Wherein the mixed butyraldehyde 1 that reaction generates enters the middle part of stabilizing tower T1 through the pipeline, and the mixed butyraldehyde liquid 3 is produced at the bottom of the tower, and the tower top material 4 enters the tower top condenser E2 through the pipeline, and the air phase 13 enters the fuel gas main pipe, and the liquid phase 5 Return to the top of the stable tower T1 through the reflux pump P1. The mixed butyraldehyde liquid 3 is preheated by the heat exchanger E1 and fed into the stabilization tower T1, and then enters the middle part of the isomer tower T2 through the pipeline. P4 enters the middle part of the n-butyraldehyde tower T3, and after the gas phase at the top of the tower is condensed by the condenser E4, a part of the liquid phase is pumped to the top of the T3 tower through the reflux pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com