CO2 trapping system on basis of thermal steam compression and spraying temperature regulation

A steam compressor and thermal technology, applied in inorganic chemistry, chemical industry, through absorption, etc., can solve the problems of the high-grade energy of superheated steam not being effectively utilized, the condensate water not being reasonably utilized, and the system energy consumption being reduced. The effect of improving thermodynamic perfection, simple structure and reducing system energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

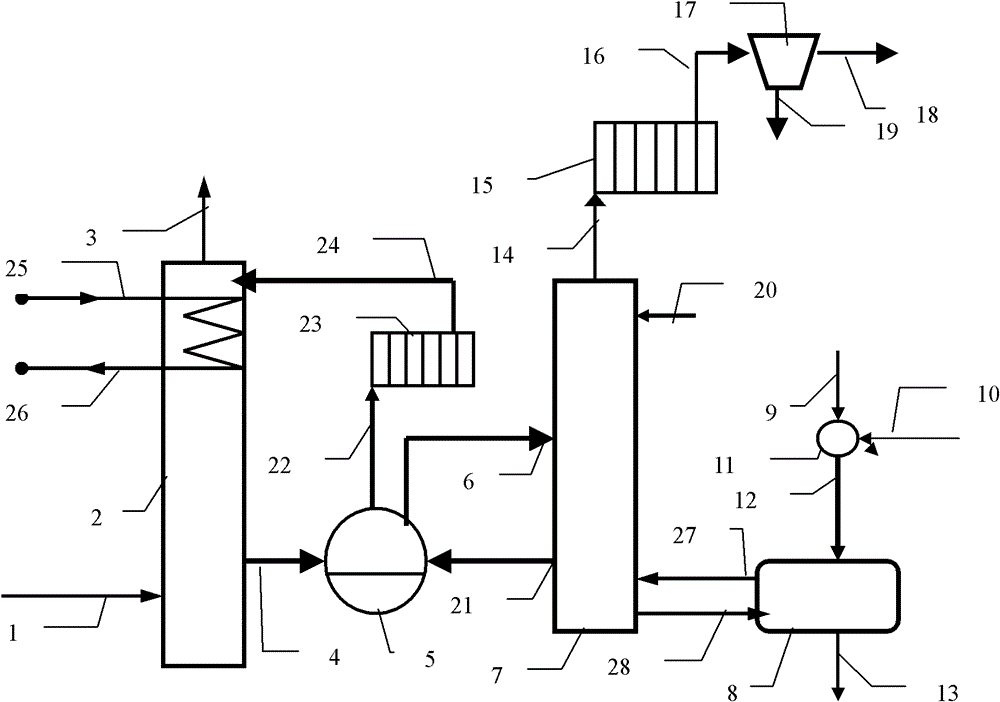

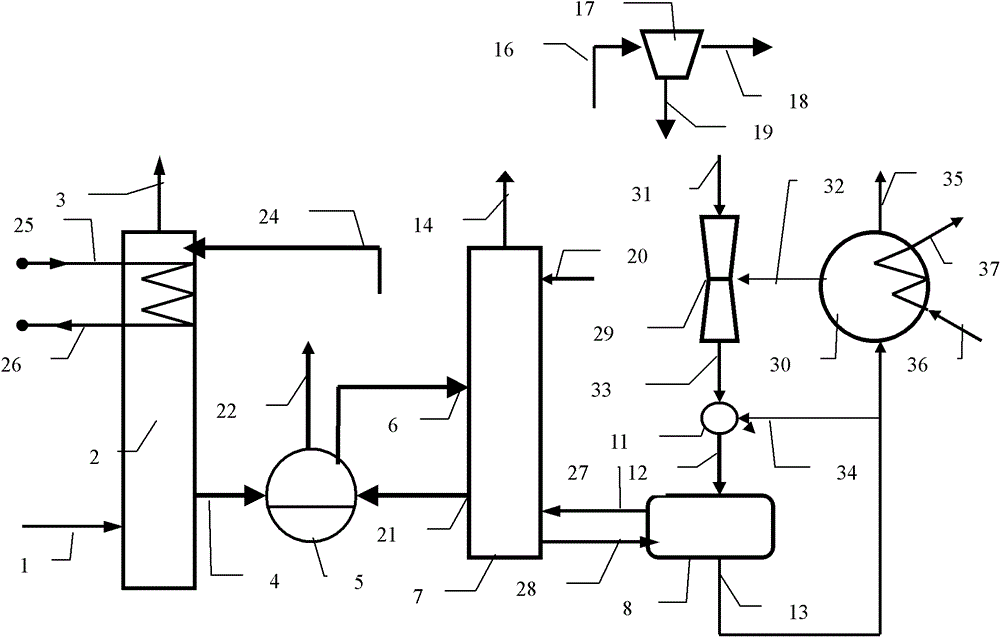

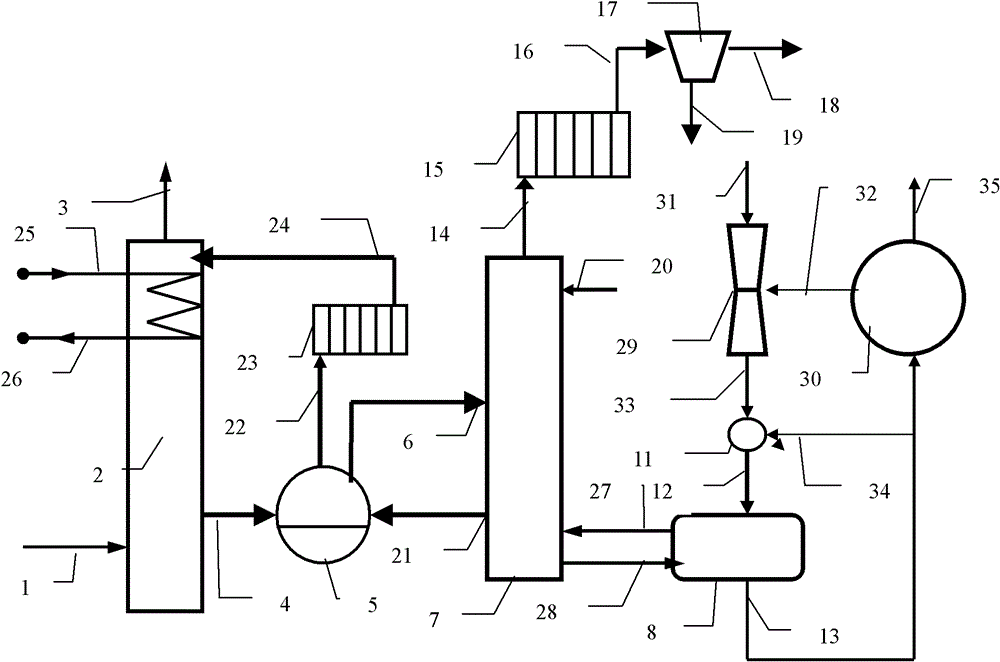

[0054] The specific implementation method is to introduce the condensed water 13 into the flash evaporator for flash evaporation, and the water vapor obtained by the flash evaporation is sent to the thermal steam compressor to be compressed to the steam parameters required by the solution boiler. In order to flash as much steam as possible, the low-grade heat generated in the system production process, the lean liquid 22 leaving the heat exchanger 5 and the regeneration gas 14 leaving the regeneration tower can be introduced into the flash-heater 30 to treat the condensed water 13 The flash process is heated. The condensed water is used to reflux, spray and cool the mixed steam, and adjust it to the temperature required by the process. Figure 2 to Figure 5 Given the recovery of condensate, recovery of condensate and CO 2 Lean liquid heat, recovery of condensed water and regeneration gas heat, recovery of condensed water, CO 2 System diagram for heat of lean liquid and regen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com