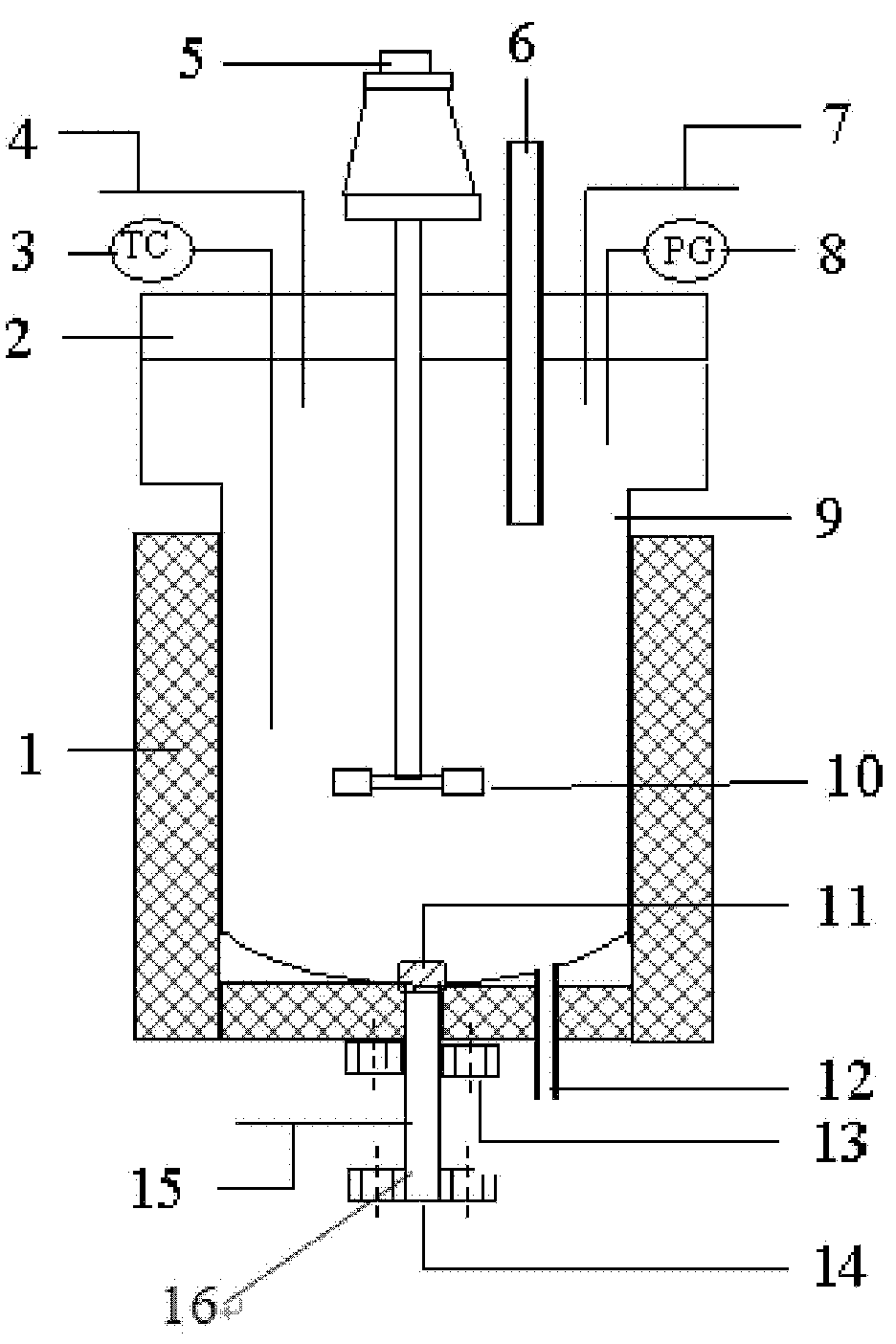

High-temperature high-pressure autoclave and using method thereof

A high-temperature, high-pressure, kettle-body technology, applied in pressure vessels used in chemical processes, solid solvent extraction, etc., can solve the problems of decreased yield of the target product and inability to ensure material separation, and achieves simple equipment, easy operation control, and stable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

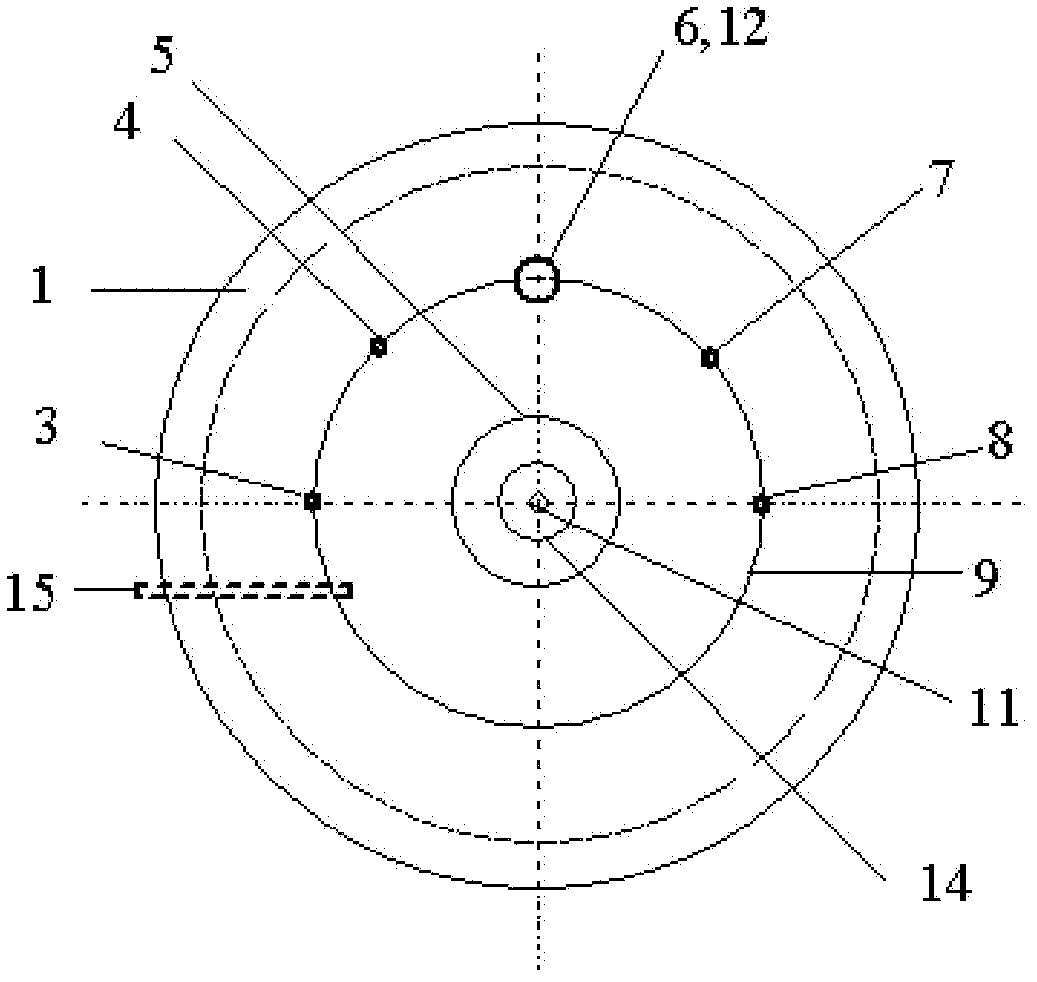

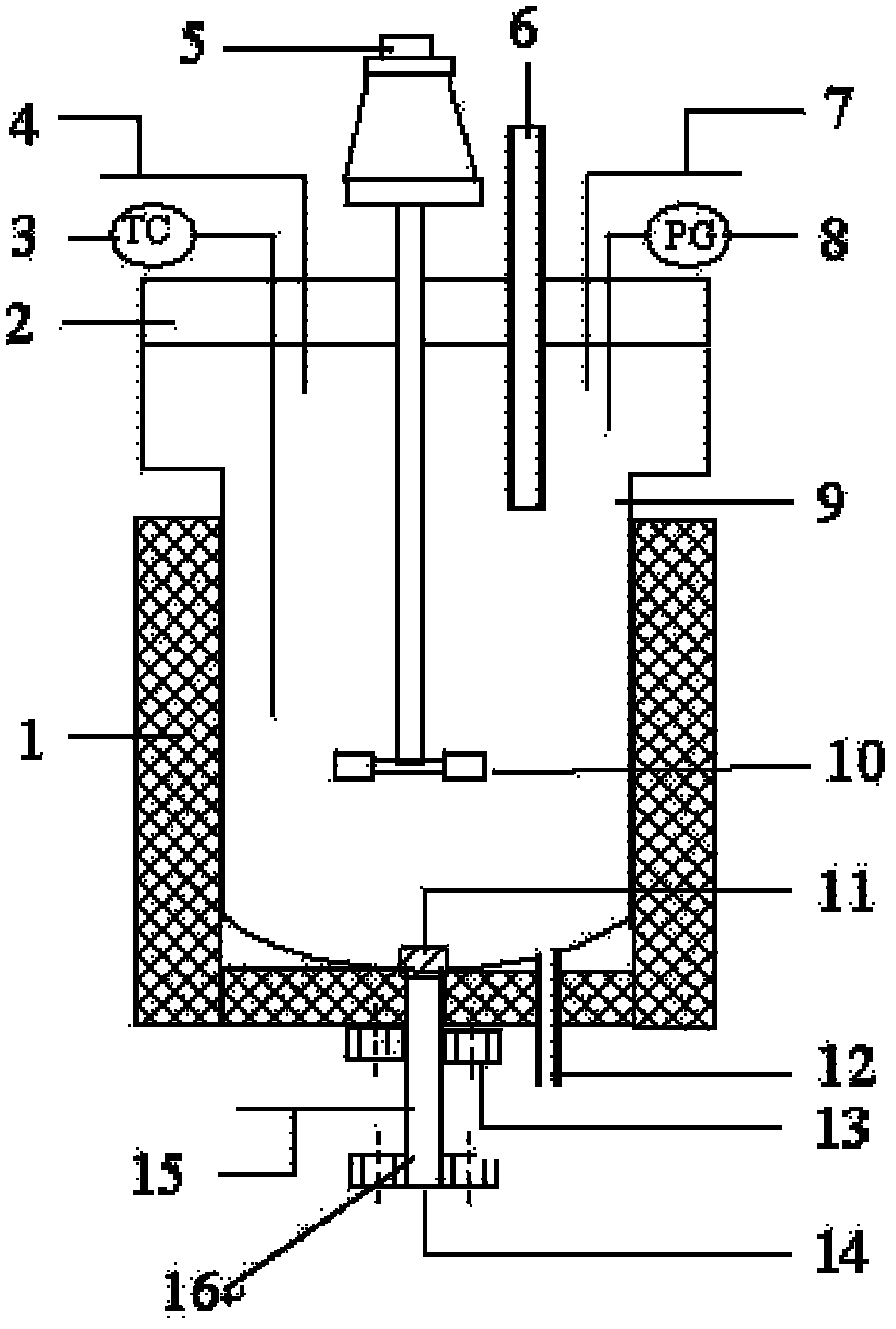

Method used

Image

Examples

Embodiment 1

[0051] Use this high-temperature and high-pressure autoclave to carry out thermal extraction on coal. Take 300g of dry coal particles with a particle size of ≤200μm and dry them at 100°C for 96 hours. According to the ratio of mass to volume, the ratio of coal particles to solvent is 1:2. Add 600ml of N-methylpyrrolidone, mix them thoroughly, and remove Add the raw material inlet 6 on the cover 2 into the high-temperature autoclave, replace the air in the high-pressure reactor with nitrogen and fill it with nitrogen to 5MPa, keep the pressure in the kettle constant within 30min, then release the nitrogen, and then fill it with nitrogen to 5MPa, Rapidly raise the temperature to 450° C. under stirring at a rotation speed of 600 rpm, and keep the temperature constant for 4 hours. After the extraction is finished, quickly open the valve on the material filter discharge device 16, use the pressure difference between the interior of the high-temperature autoclave and the receiving d...

Embodiment 2

[0053] Use this high-temperature and high-pressure autoclave to carry out thermal extraction on coal. Take 50g of dry coal particles with a particle size of ≤200μm and dry them at 150°C for 12 hours. According to the ratio of mass to volume, the ratio of coal particles to solvent is 1:12, add 600ml of 1-methylnaphthalene, and mix them thoroughly. Add the raw material inlet 6 on the kettle cover 2 into the high-temperature autoclave, replace the air in the high-pressure reactor with nitrogen and fill it with nitrogen to 5MPa, keep the pressure in the kettle constant within 30min, then release the nitrogen, and then fill it with nitrogen to 0MPa , the temperature was rapidly raised to 300°C under stirring at a rotation speed of 100 rpm, and kept at a constant temperature for 0.5 hours. After the extraction is finished, quickly open the valve on the material filter discharge device 16, use the pressure difference between the interior of the high-temperature autoclave and the rece...

Embodiment 3

[0055] Use this high-temperature and high-pressure autoclave to carry out thermal extraction on coal. Take 100g of dry coal particles with a particle size of ≤200μm and dry them at 120°C for 48 hours. According to the ratio of mass to volume, the ratio of coal particles to solvent is 1:7, add 700ml of industrial-grade national standard washing oil, and mix them thoroughly. Add the raw material inlet 6 on the kettle cover 2 into the high-temperature autoclave, replace the air in the high-pressure reactor with nitrogen and fill it with nitrogen to 5MPa, keep the pressure in the kettle constant within 30min, then release the nitrogen, and then fill it with nitrogen to 1MPa , the temperature was rapidly raised to 380° C. under stirring at a rotation speed of 400 rpm, and kept at a constant temperature for 1 hour. After the extraction is finished, quickly open the valve on the material filter discharge device 16, use the pressure difference between the interior of the high-temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com