Method for preparing efficient air purification material

A technology for purifying materials and high-efficiency air, applied in chemical instruments and methods, separation methods, inorganic chemistry, etc., can solve the problem of weak adsorption capacity of pollutants, and achieve the effect of improving health level, purifying indoor air, and preventing decoration diseases.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The specific operation steps of the preparation method of the high-efficiency indoor air purification material provided by the invention are as follows:

[0028] The first step is to weigh the weight of mineral powder (silicon-magnesium mineral fiber), add it to a high-speed mixer with a speed of less than 100rpm, cover it to seal it, and stir for 10 minutes to 30 minutes. During the stirring process, the diluted Use a watering can to spray the acid solution into the mineral powder through the liquid inlet of the mixer, then increase the stirring speed, keep it above 800 revolutions / min (rpm), and disperse for 10-30 minutes to form a semi-dry acid activation treatment;

[0029] The second step is to reduce the stirring speed to below 100rpm, open the sealing cover, add the surfactant quantitatively, seal it again and adjust the rotating speed to above 800rpm, and continue stirring for 20-30min to obtain the acid-activated-organic modified mineral fiber powder.

[0030]T...

Embodiment 1

[0034] The first step is to weigh 50kg of sepiolite mineral powder and 50kg of attapulgite mineral powder, add them to the high-speed mixer with a rotation speed of 100rpm, cover and seal it, and stir for 10 minutes. During the stirring process, add liquid Spray 12L of phosphoric acid with a concentration of 3.0M; then, adjust the rotation speed to 1000rpm, and continue stirring at high speed for 20min;

[0035] Adjust the rotation speed to 80rpm, open the sealing cover, add 2.5kg polyacrylamide, seal again and adjust the rotation speed to 1200rpm, and continue stirring for 30min to obtain acid-activated polyacrylamide modified sepiolite and attapulgite mineral powder.

[0036] The second step is to pour acid-activated polyacrylamide modified sepiolite and attapulgite mineral powder into the granulator, start the granulator, spray water mist, so that the modified clay naturally forms granules, and granulate according to needs Spherical particles with a diameter of 5mm.

[003...

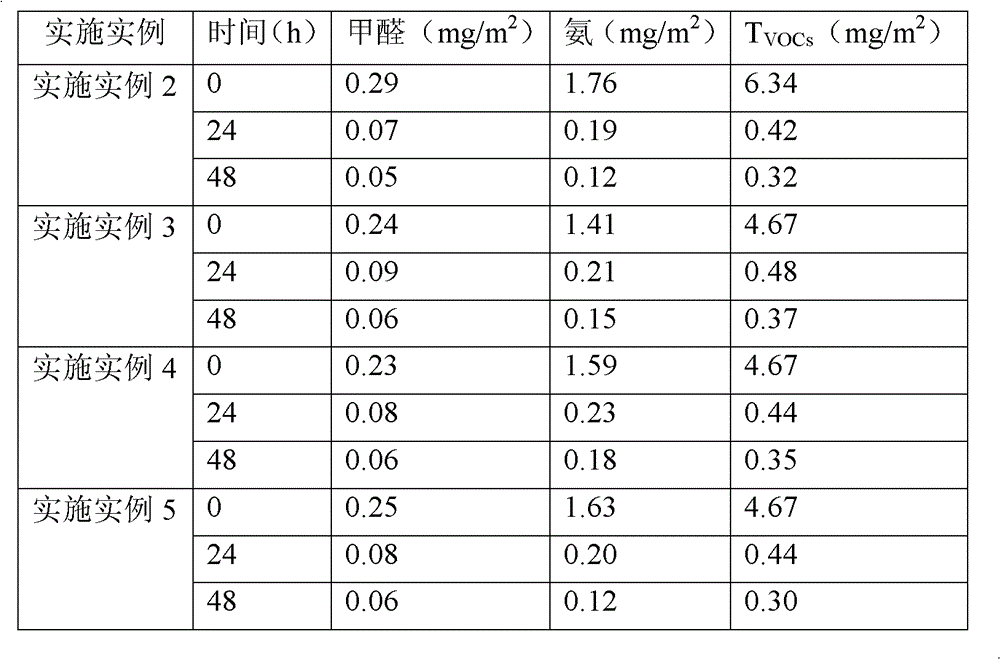

Embodiment 2

[0046] The first step is to weigh 100kg of attapulgite mineral powder, add it to a high-speed mixer with a rotation speed of 100rpm, cover it to seal it, and stir for 30 minutes. During the stirring process, spray phosphoric acid with a concentration of 5M through the liquid inlet 10L; then, adjust the rotation speed to 1000rpm, and continue to stir for 20min;

[0047] Adjust the rotation speed to 80 rpm, open the sealing cover, add 3 kg of polyacrylamide, seal it again and adjust the rotation speed to 1200 rpm, and continue stirring for 30 minutes to obtain acid-activated polyacrylamide modified attapulgite mineral powder.

[0048] The second step is to pour the acid-activated polyacrylamide modified attapulgite mineral powder into the granulator, start the granulator, spray water mist, so that the modified clay naturally forms particles, and the particle size is 2.0mm as required spherical particles.

[0049] In the third step, the spherical particles obtained in the second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com