Composite melt-blown filter core material filled with feather fiber, and preparation device and method thereof

A feather fiber, melt-blown filter element technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problem of long forming process, inconvenient use of feather non-woven composite filter materials, and large equipment investment. and other problems, to achieve the effect of solving difficult repeated use, overall good, and increasing filling amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

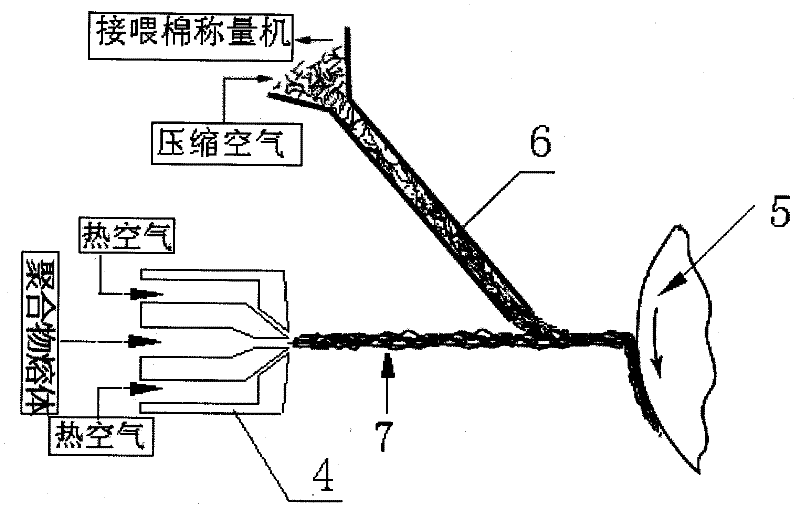

[0031] Such as image 3 As shown, it is a schematic structural diagram of a preparation device for a composite melt-blown filter material. The preparation device for a composite melt-blown filter material includes a traditional melt-blown device and a feather fiber feeding device. The traditional melt-blown device includes a screw extruder Exit machine 4 and filter core receiving winding device 5, described feather fiber feeding device comprises round tube 6, air compressor and ZBG011 type cotton feeding weighing machine, the upper nozzle of round tube 6 is connected with ZBG011 through a trumpet joint The outlet of the cotton-feeding weighing machine is connected, the compressed air outlet of the air compressor is connected with the outlet of the ZBG011-type cotton-feeding weighing machine, and the compressed air generated by the air compressor enters from the outlet of the cotton-feeding weighing machine. The diameter of the circular tube 6 is 80mm, and the lower nozzle of t...

Embodiment 2

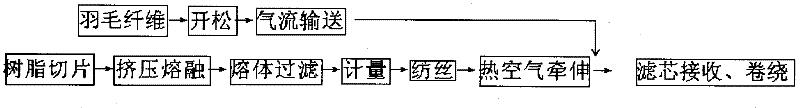

[0033] Such as figure 2 As shown, it is a flow chart of the preparation method of the composite melt-blown filter material, and the specific steps of the preparation method of the composite melt-blown filter material are:

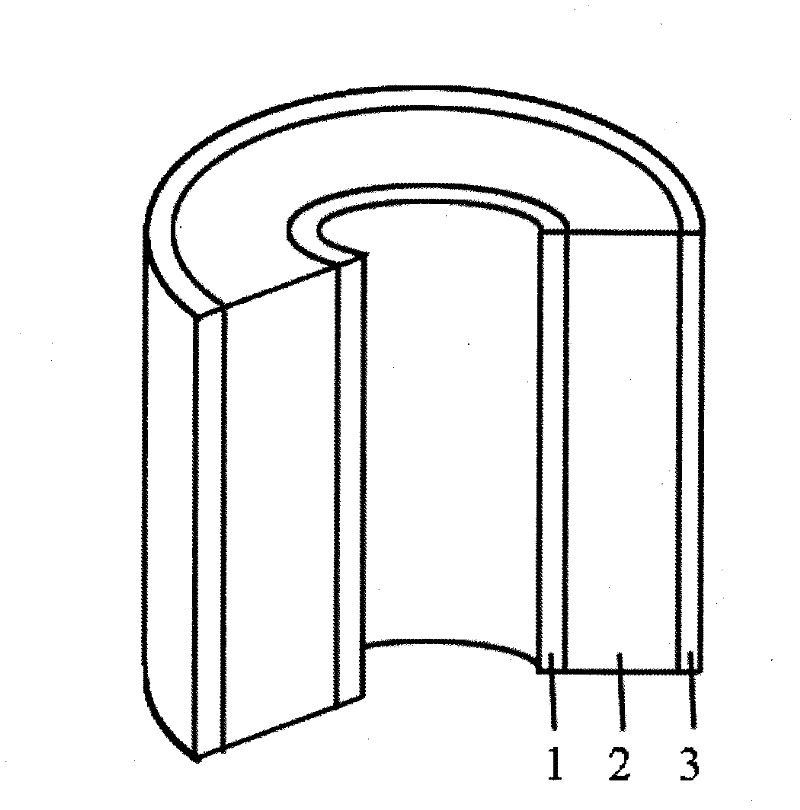

[0034](1) The low-density polyethylene resin chip of 888-000 produced by China Petrochemical Co., Ltd. is heated and extruded by screw extruder 4 to become a molten state, and enters the spinneret hole after being filtered by a filter and metered by a metering pump. After being extruded from the spinneret hole, it reaches the filter element receiving and winding device 5 under hot air drafting, and then cooled to form the core layer 1 of the composite filter element material. Specific process parameters: the temperature of the screw extruder 4 is 220°C, the number of spinneret holes of the screw extruder 4 is 600, the extrusion rate of each die spinneret hole is 0.3g / min, and the hot air is drawn. The temperature is 360°C and the pressure is 0.3MPa; the h...

Embodiment 3

[0039] Such as figure 2 As shown, it is a flow chart of the preparation method of the composite melt-blown filter material, and the specific steps of the preparation method of the composite melt-blown filter material are:

[0040] (1) S2040 polypropylene resin slices produced by China Petroleum and Chemical Corporation are heated and extruded by a screw extruder to become a molten state. After being filtered by a filter and metered by a metering pump, they enter the spinneret hole and are extruded through the spinneret hole. Finally, it reaches the filter element receiving and winding device under hot air drafting, and then cools and forms the core layer of composite filter element material. Specific process parameters: the temperature of the screw extruder is 230°C, the number of spinneret holes of the screw extruder 4 is 600, and the extrusion rate of each die spinneret hole is 0.4g / min; the temperature of the hot air for drawing The temperature is 360°C, the pressure is 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com