Electric-hydro complex brake system employing integral brake master cylinder assembly

A brake master cylinder, electro-hydraulic composite technology, applied in the direction of brake transmission, brake, transportation and packaging, can solve problems such as increasing hydraulic source, achieve easy processing, improve braking efficiency, and flexible pedal feel design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

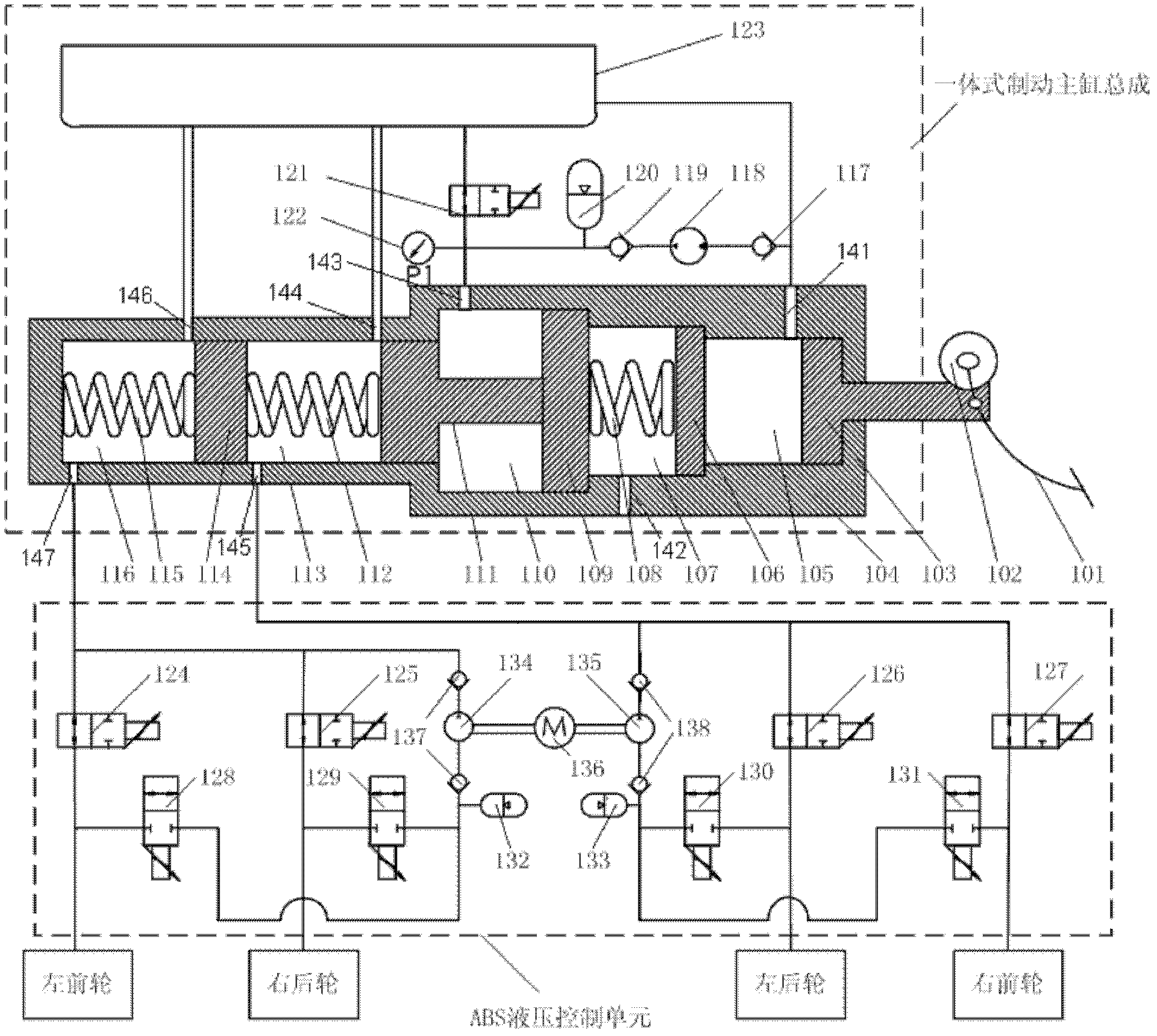

[0032] Such as figure 1 As shown, it is a schematic diagram of the present invention in the initial state, the master cylinder push rod 104 of the integrated brake master cylinder assembly, the first booster piston 107, the second booster piston 110, the first master cylinder piston 112, the second master cylinder The two pistons 115 are at the far right side under the action of the first return spring 112, the second return spring 115 and the pedal feeling simulation spring 108, i.e. the initial position; The cylinder rear chamber 114 and the master cylinder front chamber 117 communicate with the liquid storage chamber 123 through the first through hole 141, the third through hole 143, the fourth through hole 144 and the sixth through hole 146 on the cylinder body 104 respectively. The chamber 114 and the front chamber 117 of the master cylinder communicate with the two input ports of the ABS hydraulic control unit through the fifth through hole 145 and the seventh through ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com