Preparation method of cell grade ferric orthophosphate

A technology of ferric orthophosphate and its production method, which is applied in the field of phosphorus chemical industry, can solve the problems of high cost of battery-grade ferric orthophosphate, and achieve the effects of environmental protection, cost reduction, and improvement of recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

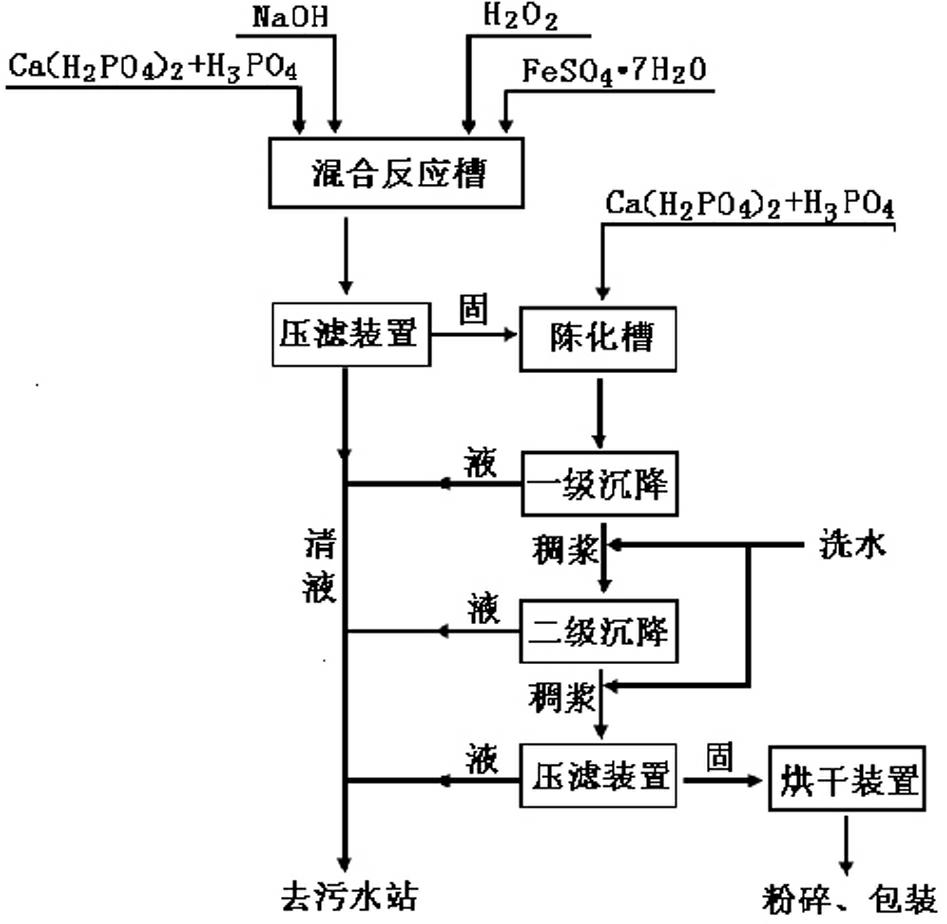

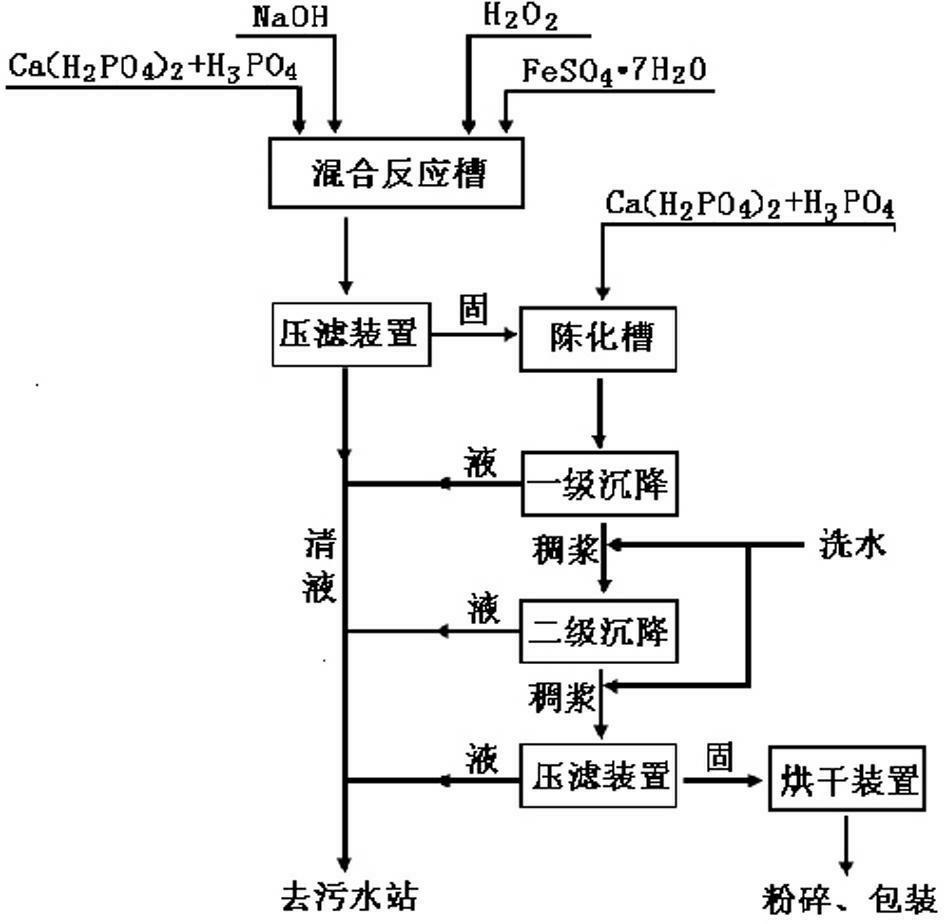

Method used

Image

Examples

Embodiment 1

[0026] The clarified liquid (containing P 2 o 5 8~12%) as raw material, pour into the reaction vessel, control the temperature at 80°C, add 3.5% industrial grade NaOH by weight while stirring, and fully dissolve it. In the sodium phosphate salt solution after the reaction, the molar ratio is 1:1 Join FeSO 4 ·7H 2 O solution, adding 2% catalyst H by weight 2 o 2 , control the pH value at the end point to ≈1.5, and maintain the reaction for 1 hour to obtain a crude ferric phosphate slurry, which is filtered through a plate and frame filter press and washed repeatedly with water to obtain a ferric phosphate filter cake; Min mechanical stirring to carry out crystal conversion, and adjust the acidity and P with the raw material liquid 2 o 5 Concentration, maintain H +1 0.7g / L and P 2 o 5 At 80°C, age and crystallize for 1 hour; filter and wash the aged residue repeatedly with water until the free phosphoric acid in the filter cake is ≤0.05%, sulfuric acid ≤0.0015%, and a...

Embodiment 2

[0028] The clarified liquid (containing P 2 o 5 8~12%) as raw material, pour into the reaction vessel, control the temperature at 80°C, add 3.2% industrial grade NaOH by weight while stirring, and fully dissolve it. In the sodium phosphate salt solution after the reaction, the molar ratio is 1:2 Join FeSO 4 ·7H 2 O solution, adding 5% catalyst H by weight 2 o 2 , control the end-point pH value to ≈1.5, and maintain the reaction for 1.5 hours to obtain crude ferric phosphate slurry, which is filtered through a plate and frame filter press and washed repeatedly with water to obtain a ferric phosphate filter cake; the filter cake is put into an aging tank and heated at 200 r / min under mechanical stirring for crystal conversion, and adjust the acidity and P with the raw material solution 2 o 5 Concentration, maintain H +1 0.9g / L and P 2 o5 22g / L, aged and crystallized at 90°C for 5 hours; the aged slag was repeatedly filtered and washed with water until the free phospho...

Embodiment 3

[0030] The clarified liquid (containing P 2 o 5 8~12%) as raw material, inject into the reaction vessel, control the temperature at 85°C, add 4% by weight industrial grade NaOH while stirring, fully dissolve, in the sodium phosphate salt solution after the reaction, the molar ratio is 1:2 Join FeSO 4 ·7H 2 O solution, adding 3% catalyst H by weight 2 o 2 , control the end-point pH value to ≈1.5, and maintain the reaction for 1.2 hours to obtain crude ferric phosphate slurry, which is filtered through a plate and frame filter press and washed repeatedly with water to obtain a ferric phosphate filter cake; the filter cake is put into an aging tank and heated at 150 r / min under mechanical stirring for crystal conversion, and adjust the acidity and P with the raw material solution 2 o 5 Concentration, maintain H +1 0.75g / L and P 2 o 5 At 85°C, age and crystallize for 4 hours; filter and wash the aged slag repeatedly with water until the free phosphoric acid in the filt...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap