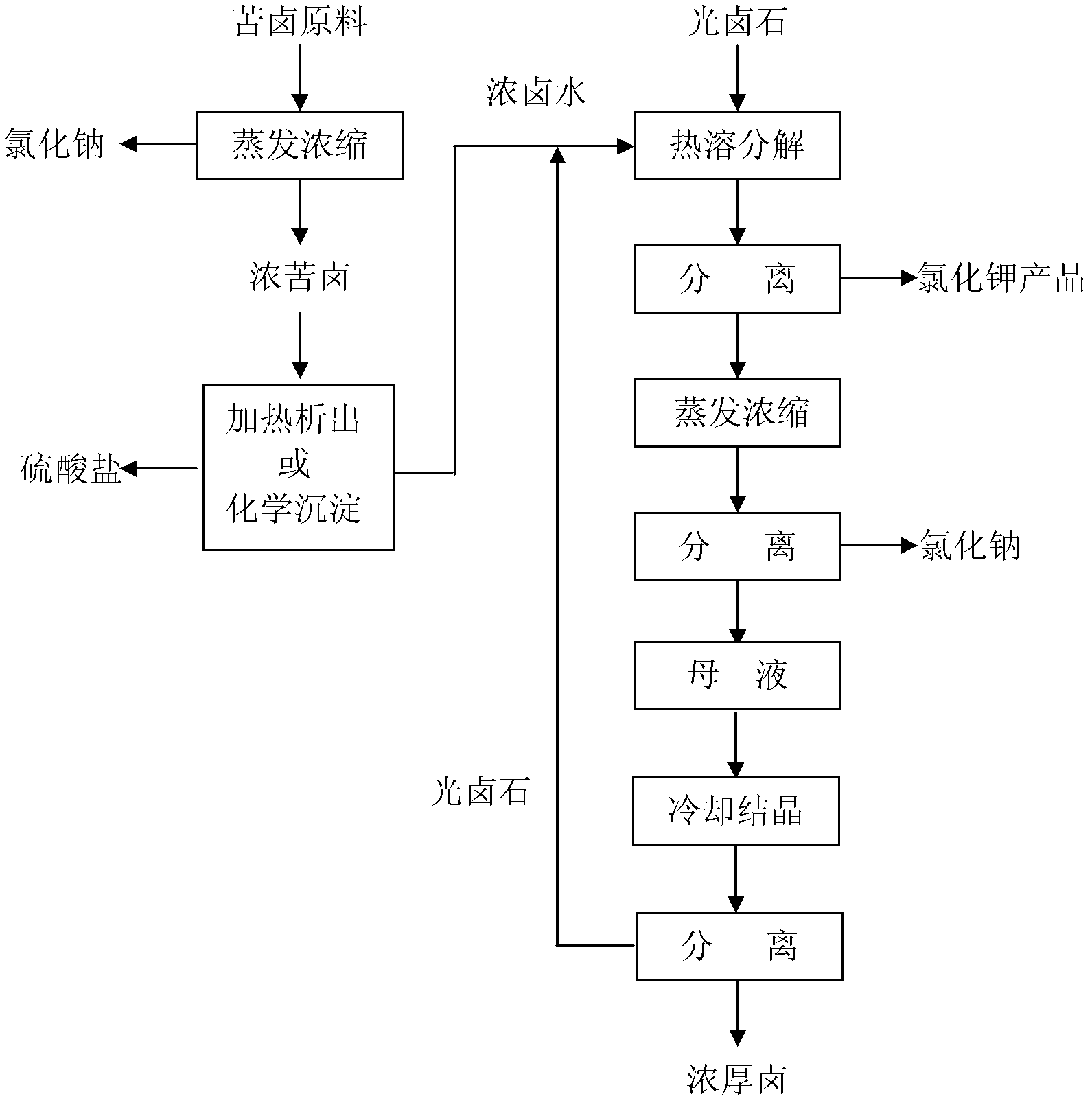

Method for preparing potassium chloride through decomposing carnallite by concentrated brine

A technology of carnallite and potassium chloride, which is applied in the direction of alkali metal chlorides, can solve the problems of high energy consumption, large investment, and low efficiency, and achieve the effects of improving economic efficiency, solving large evaporation, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

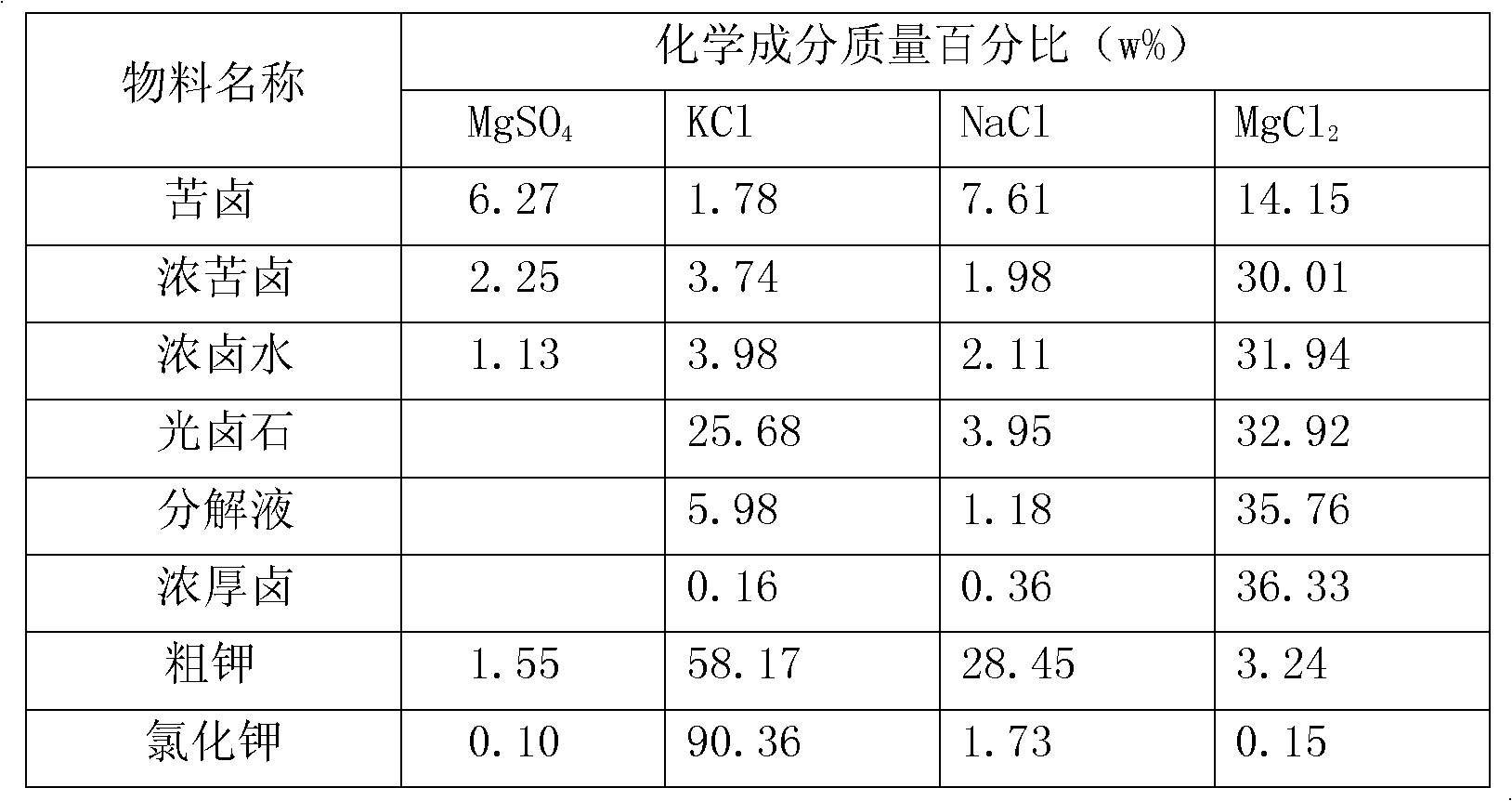

Embodiment 1

[0026] The first step is to obtain concentrated bittern from the raw bittern through concentration

[0027] Put 2800 g of bittern as a raw material in an evaporator, evaporate and concentrate until the boiling temperature of the feed liquid in the evaporator is 123° C., keep warm at 118° C., and remove the precipitated sodium chloride through solid-liquid separation to obtain 1150 g of concentrated bittern;

[0028] The second step is to prepare concentrated brine from concentrated bittern

[0029] The concentrated bittern obtained in the first step is heated up to a temperature of 140°C in an autoclave with a pressure of 0.2MPa, then cooled to 120°C, and the precipitated magnesium sulfate is removed through solid-liquid separation to obtain 1138g of concentrated bittern. In the obtained concentrated bittern The magnesium sulfate content is 2.2%;

[0030] The third step is to decompose carnallite with concentrated brine to prepare potassium chloride

[0031] The concentrated...

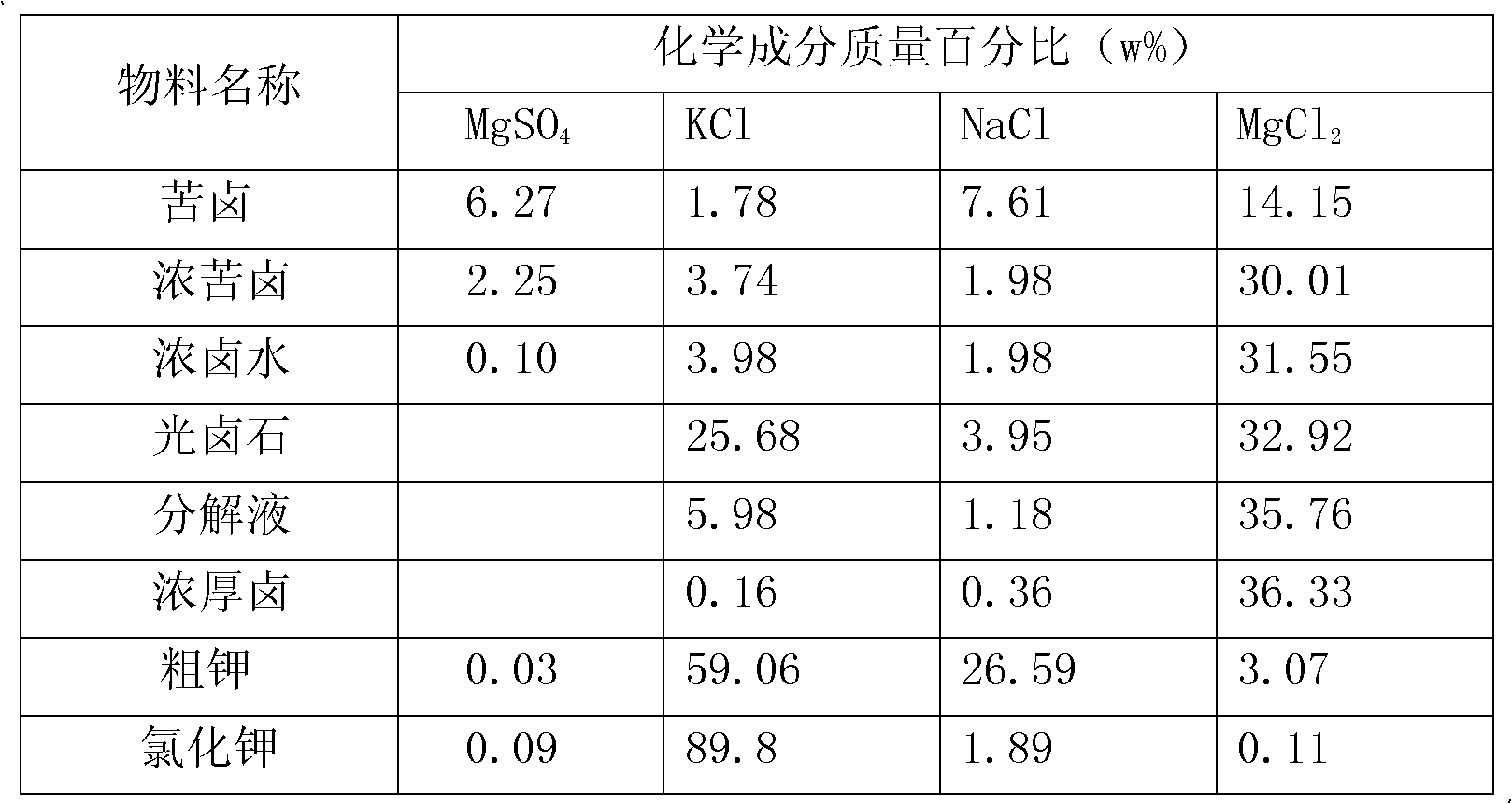

Embodiment 2

[0038] The first step is to obtain concentrated bittern from the raw bittern through concentration

[0039] Put 2800 g of raw bittern in an evaporator, evaporate and concentrate until the boiling point temperature of the liquid in the evaporator is 119°C, keep warm at 118°C, and remove the precipitated sodium chloride through solid-liquid separation to obtain 1150g of concentrated bittern;

[0040] The second step is to prepare concentrated brine from concentrated bittern

[0041] The concentrated bittern obtained in the first step is heated up to a temperature of 250°C in an autoclave with a pressure of 0.8MPa, then cooled to 120°C, and the precipitated magnesium sulfate is removed through solid-liquid separation to obtain 1131g of concentrated bittern. In the obtained concentrated bittern The magnesium sulfate content is 2.0%;

[0042] The third step is to decompose carnallite from concentrated brine to produce potassium chloride

[0043] The concentrated brine prepared in...

Embodiment 3

[0048] The first step is to obtain concentrated bittern from the raw bittern through concentration

[0049] 2800g of the bittern raw material was evaporated and concentrated by an evaporator until the temperature of the liquid in the evaporator was 126°C, kept at 120°C, and the precipitated sodium chloride was removed through solid-liquid separation to obtain 1150g of concentrated bittern;

[0050] The second step is to obtain concentrated brine from concentrated bittern

[0051] The concentrated bittern obtained in the first step is heated to a temperature of 270 ° C in an autoclave with a pressure of 0.85 MPa, then cooled to 120 ° C, and then the magnesium sulfate precipitated is removed through solid-liquid separation to obtain 1130 g of concentrated bittern, and the obtained concentrated bittern is The magnesium sulfate content is 1.9%;

[0052] The third step is to decompose carnallite from concentrated brine to produce potassium chloride

[0053] The concentrated brine o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com