Method for removing nitrogen and phosphorus by MBBRs (Moving Bed Biofilm Reactors) with sectionalized water inflow

A technology for denitrification and dephosphorization, staged water intake, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. Increased film thickness and other issues, to achieve the effect of superior adaptation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

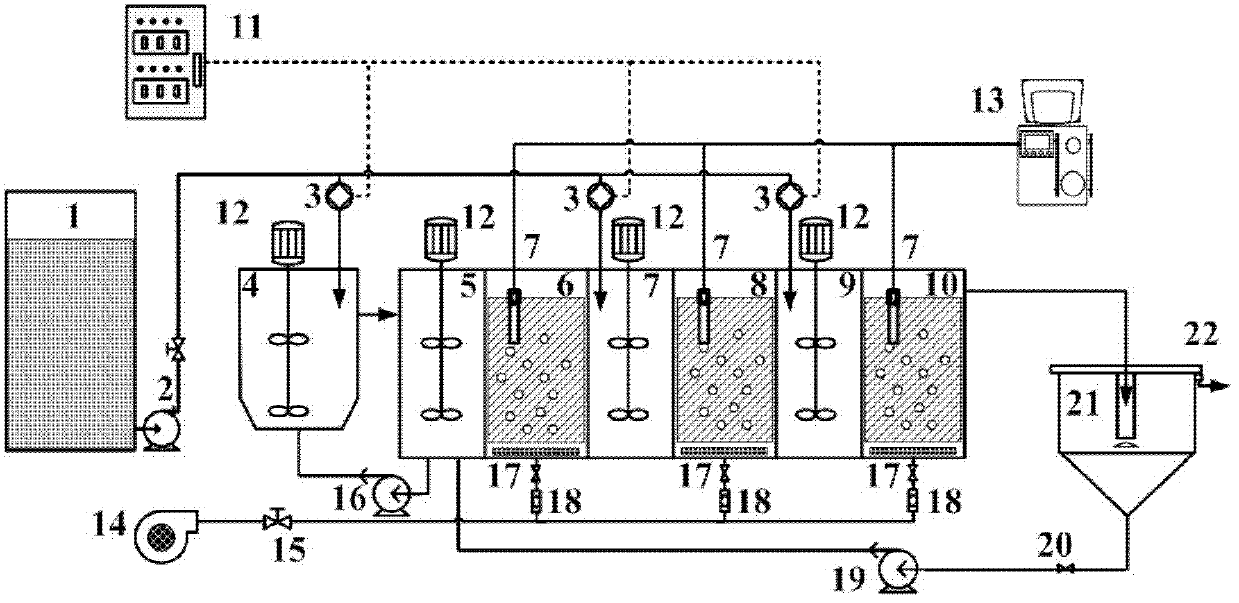

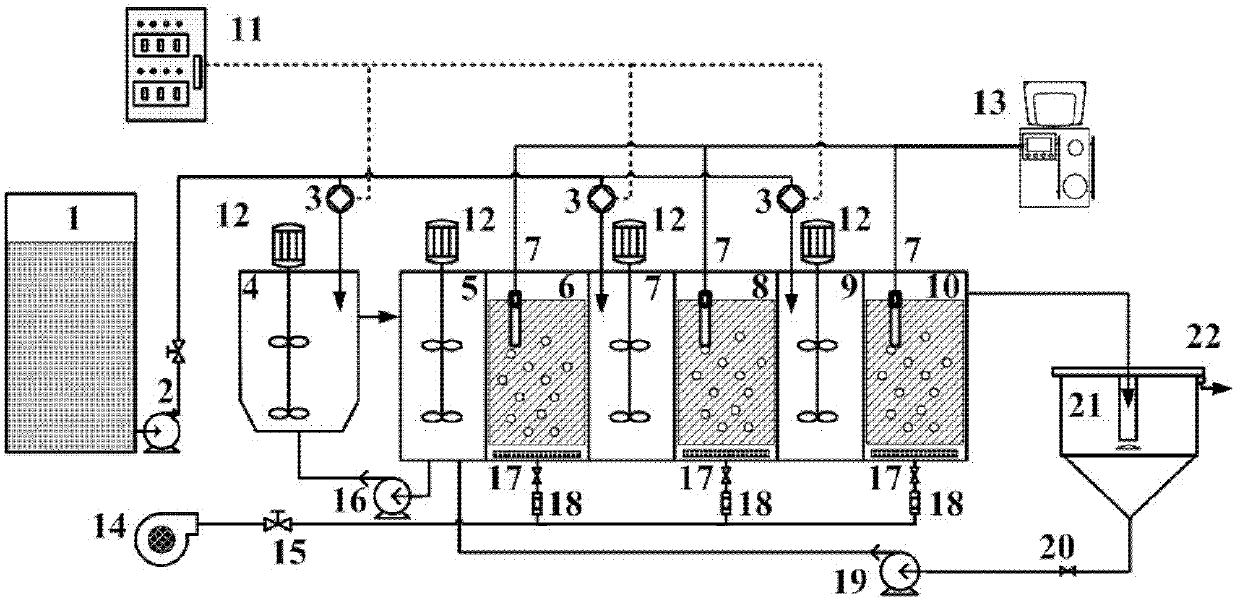

[0022]In the present invention, the raw water tank, the water inlet pump and the main body bioreactor are connected by the water inlet pipe, the main body bioreactor is connected with the sedimentation tank, the sedimentation tank is connected with the anoxic reactor of the first stage through the backflow pump and the check valve, and the supernatant is discharged from the The water outlet is discharged; the main bioreactor is divided into 7 areas by the open-hole partition, and the partition is provided with connecting pipes; along the water inlet direction, there are anaerobic reactor, the first stage of anoxic reactor, and the first stage of fluidized bed Biofilm reactor, second stage anoxic reactor, second stage fluidized bed biofilm reactor, third stage anoxic reactor, third stage fluidized bed biofilm reactor. Through the control system to control the segmented water inlet pump, the raw water enters the system in three stages, respectively anaerobic reactor, second stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com