Steel slag masonry cement and preparation method thereof

A technology for building cement and steel slag, applied in the field of building materials, can solve the problems of low hydration performance of vanadium-containing steel slag, no mention of power plant slag, no raw materials for steel slag, etc., and achieves the effect of enhancing activity, improving cement performance and making up for insufficient activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0019] Steel slag masonry cement is prepared by mixing 20-50 parts by weight of cement clinker, 15-40 parts by weight of power plant slag, 3-15 parts by weight of admixture and 30-60 parts by weight of vanadium-containing steel slag; Calcium oxide content is not more than 3% by weight; the admixture is composed of 50-100% of gypsum, 0-10% of triethanolamine and 0-50% of sodium sulfate.

[0020] The present invention controls the content of free calcium oxide in the vanadium-containing steel slag to ≤3% and mixes the vanadium-containing steel slag, power plant slag and admixture in proportion. In addition, those skilled in the art can understand that the specific surface area of the steel slag road cement also reaches a certain level. requirements, so that vanadium-containing steel slag and power plant slag can be used as raw materials for steel slag masonry cement, and the prepared cement can meet the performance requirements of steel slag masonry cement in "Steel Slag Masonr...

Embodiment 1

[0033] The basic index of the vanadium-containing steel slag made of vanadium-containing steel slag after thermal braising process, magnetic separation, screening and grinding is: specific surface area 411m 2 / kg, the metallic iron content is 0.5%, and the free calcium oxide content is 2.45%.

[0034] Mix 40 parts by weight of vanadium-containing steel slag after treatment, 30 parts by weight of power plant slag, 25 parts by weight of cement clinker, and 5 parts by weight of modifier and grind to obtain steel slag masonry cement. The specific surface area of steel slag masonry cement is 365m 2 / kg. Wherein, the modifying agent is composed of 90% of gypsum and 10% of triethanolamine by weight.

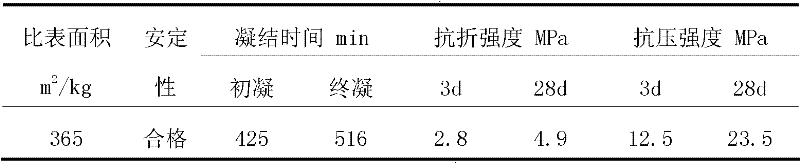

[0035] The properties of the prepared steel slag masonry cement are shown in Table 1.

[0036] Table 1 Example 1 steel slag masonry cement performance table

[0037]

Embodiment 2

[0039] The basic index of the vanadium-containing steel slag made of vanadium-containing steel slag after thermal braising process, magnetic separation, screening and grinding is: specific surface area 411m 2 / kg, the metallic iron content is 0.5%, and the free calcium oxide content is 2.45%.

[0040] Mix 50 parts by weight of vanadium-containing steel slag after treatment, 20 parts by weight of power plant slag, 20 parts by weight of cement clinker, and 10 parts by weight of modifier and grind to obtain steel slag masonry cement. The specific surface area of steel slag masonry cement is 370m 2 / kg. Wherein, the modifying agent is composed of 85% of gypsum, 5% of triethanolamine and 10% of sodium sulfate by weight.

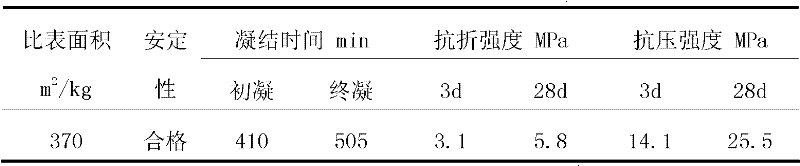

[0041] The properties of the prepared steel slag masonry cement are shown in Table 2.

[0042] Table 2 Example 2 steel slag masonry cement performance table

[0043]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com