Compound fertilizer and preparation method thereof

A compound fertilizer and ammonium nitrate technology, applied in the agricultural field, can solve the problems of single nutrient and low concentration, and achieve the effects of improving water solubility, low cost, and overall cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0091] The present invention also provides a method for preparing compound fertilizer as described in any one of the above, comprising the following steps:

[0092] A. Phosphate rock is treated by chemical reaction with nitric acid;

[0093] B. with ammonia NH The reaction product that step A obtains is processed;

[0094] C. process the reaction product that step B obtains with ammonium nitrate; Reaction time 10~30min

[0095] D. Granulation;

[0096] E. Packaging.

[0097] In some embodiments,

[0098] In step A, the temperature at which the chemical reaction occurs is preferably 50°C to 80°C;

[0099] and / or,

[0100] The concentration of the nitric acid is preferably 50% to 70%;

[0101] and / or,

[0102] The mass addition ratio of the phosphate rock and the nitric acid is preferably 1:1-2;

[0103] and / or,

[0104] The chemical reaction occurring between the phosphate rock and the nitric acid is preferably:

[0105] 2Ca 5 F(PO4) 3 +15HNO 3 =5Ca 3 (NO 3...

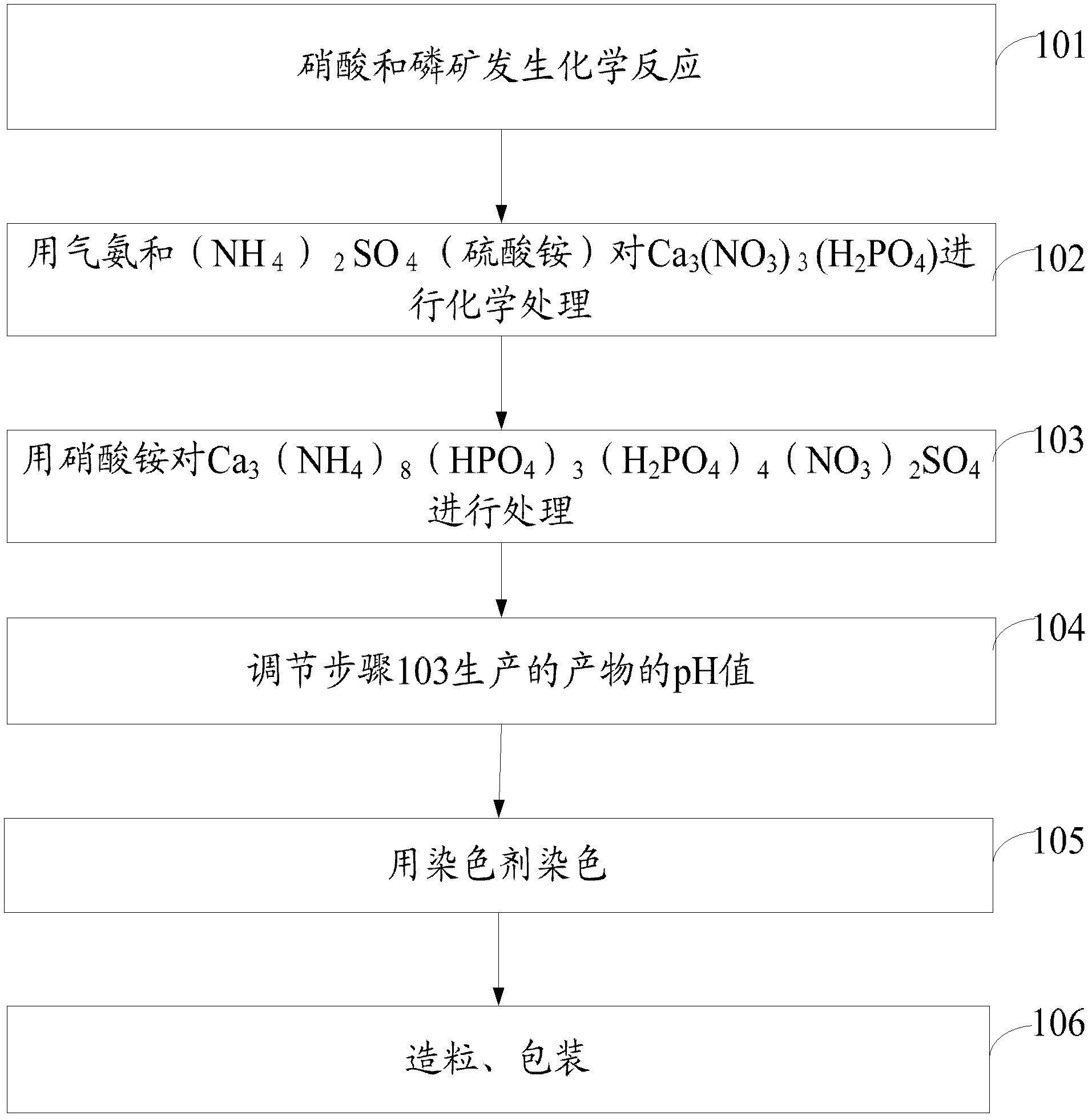

specific Embodiment 1

[0124] Specific embodiment 1, preparation Ca 3 (NH 4 ) 8 HPO 4 ) 3 (H 2 PO 4 ) 4 (NO 3 ) 2 SO 4 ~NH 4 NO 3 ,like figure 1 , as shown in:

[0125] Step 101, chemical reaction occurs between nitric acid and phosphate rock;

[0126] Nitric acid and phosphate rock undergo a chemical reaction, and nitric acid can directly decompose phosphate rock to obtain the nutrients needed by crops;

[0127] Among them, the concentration of nitric acid is preferably 50% to 70%. It should be noted that the above-mentioned range includes any value in this interval, as long as the points included in the above-mentioned ratio range are the scope of protection of the present invention, such as: 50%, 52%, 54%, 56%, 58%, 60%, 62%, 64%, 66%, 68%, 70% or the range between any two values, preferably 56%;

[0128] The reaction temperature is 50°C to 80°C; it should be noted that the above-mentioned range includes any value in the interval, as long as the points included in the above-mention...

specific Embodiment 2

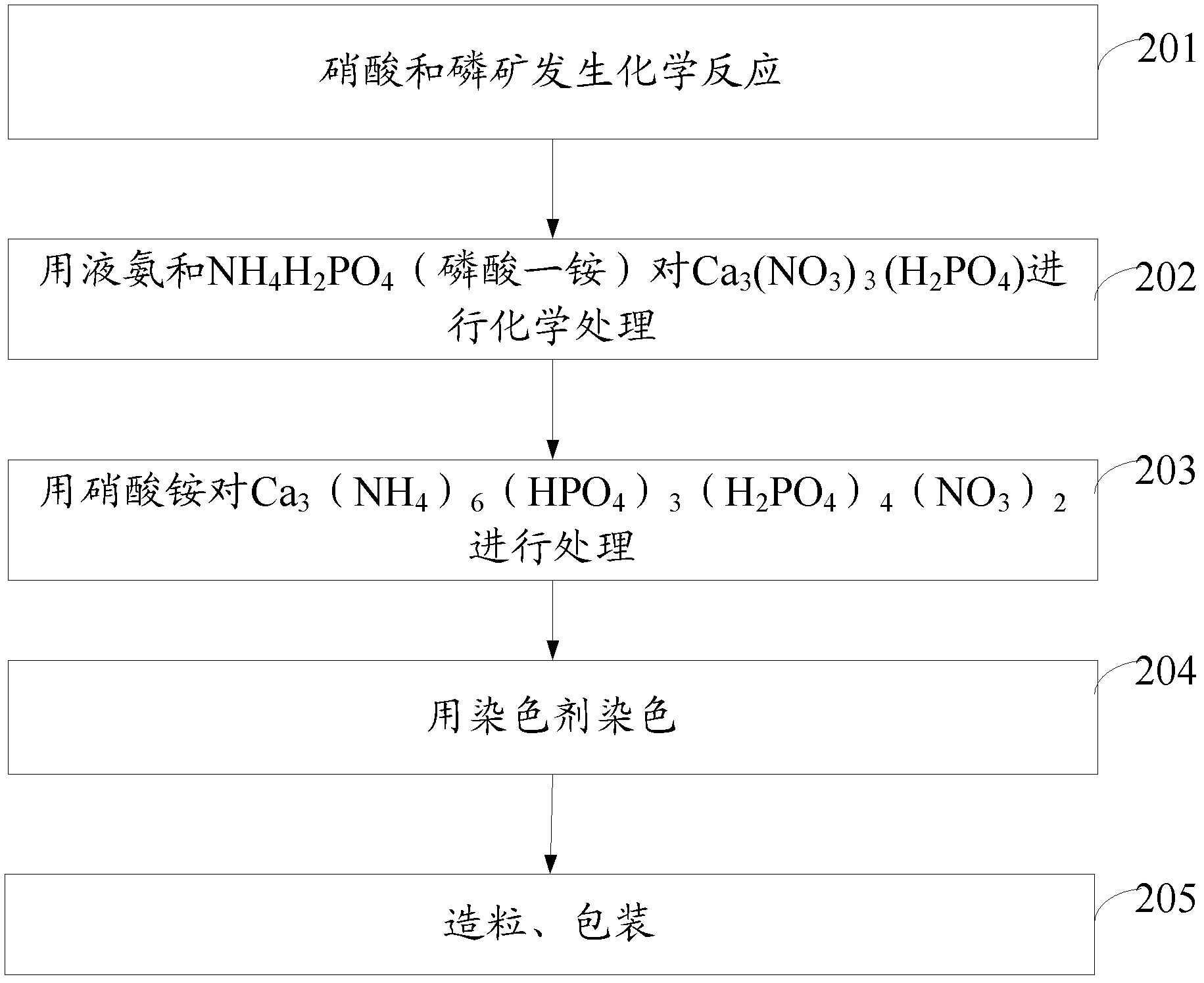

[0155] Specific embodiment 2, preparation Ca 3 (NH4 ) 6 (HPO 4 ) 3 (H 2 PO 4 ) 4 (NO 3 ) 2 ~NH 4 NO 3 ,like figure 2 , as shown in:

[0156] Step 201, a chemical reaction occurs between nitric acid and phosphate rock;

[0157] Nitric acid and phosphate rock undergo a chemical reaction, and nitric acid can directly decompose phosphate rock to obtain the nutrients needed by crops;

[0158] Among them, the concentration of nitric acid is preferably 50% to 70%. It should be noted that the above-mentioned range includes any value in this interval, as long as the points included in the above-mentioned ratio range are the scope of protection of the present invention, such as: 50%, 52%, 54%, 56%, 58%, 60%, 62%, 64%, 66%, 68%, 70% or the range between any two values, preferably 56%;

[0159] The reaction temperature is 50°C to 80°C; it should be noted that the above-mentioned range includes any value in the interval, as long as the points included in the above-mentioned r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com