Phenol sodium salt treatment method and device

A treatment method and treatment device technology, applied in the field of coal chemical industry, can solve the problems of unsafe neutralization of dilute sulfuric acid, high cost, damage to the earth environment, etc., and achieve the effect of avoiding high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for treating sodium phenolate. An embodiment of the present invention provides a method for treating sodium phenate, which uses carbon dioxide in power generation tail gas to dissolve in water to generate carbonic acid, and uses carbonic acid to neutralize sodium phenate.

[0027] In the embodiment of the present invention, sodium phenate is produced in the process of utilizing coal tar to process dephenolized oil. The coal tar is a mixture of hydrocarbons, which at least includes light oil, phenol oil, naphthalene oil, washing oil anthracene oil and asphalt Wait. The coal tar produces sodium phenate when extracting crude phenol and making dephenolized oil. The chemical formula of sodium phenate is RONa, where R refers to phenol, cresol or xylenol. The reaction expression is:

[0028] 2RONa+CO 2 +H 2 O==2ROH+NaCO 3 , wherein, ROH refers to crude phenol or dephenolized oil.

[0029] In a preferred embodiment, sodium phenolate can be obtained by alkaline cl...

Embodiment 2

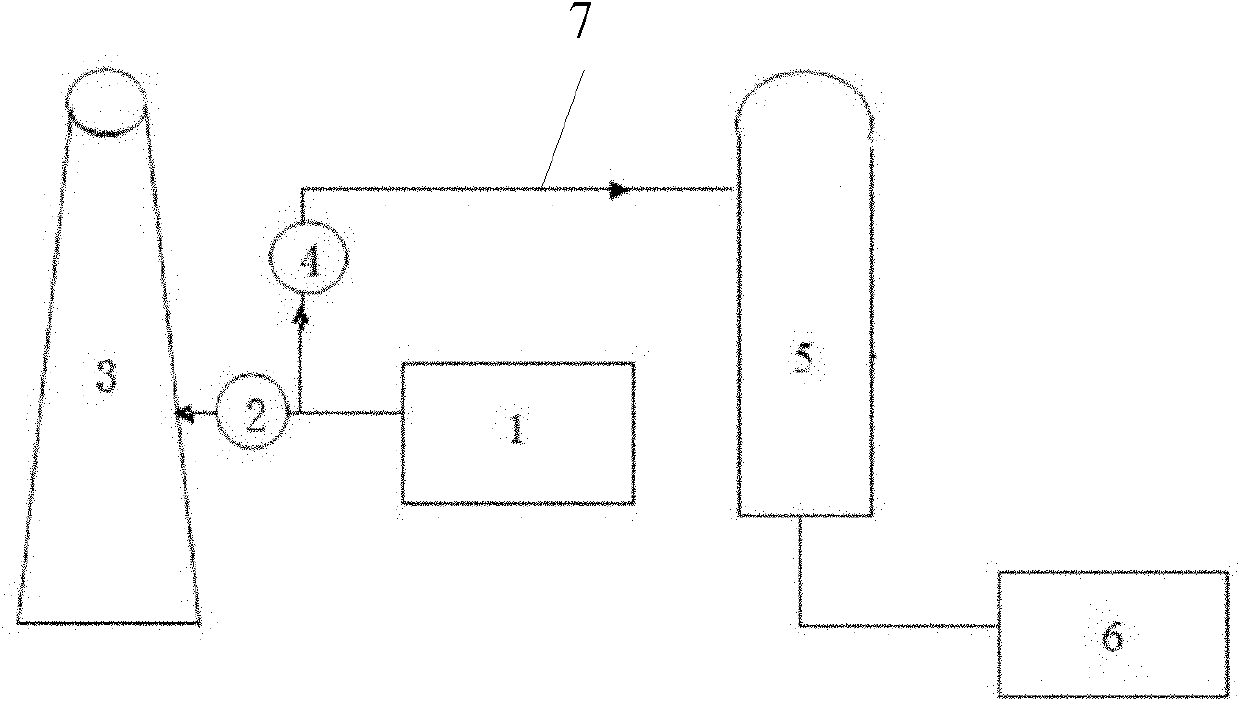

[0033] A sodium phenate treatment device. see figure 1 , figure 1 It is a simplified schematic diagram of the sodium phenol salt treatment device provided in the embodiment of the present invention.

[0034] Such as figure 1 As shown, the sodium phenate treatment device provided in the embodiment of the present invention includes a regulating valve 4 , a reaction tower 5 , a waste liquid collection tank 6 and a conduit 7 . Of course, the sodium phenate salt treatment device in the embodiment of the present invention also includes various other conventional components or structures. Here, this embodiment only describes the parts related to the invention points of this embodiment. For specific components or structures, you can refer to the existing Appropriate additions and subtractions of conventional implementations do not constitute limitations on the present invention.

[0035] In the present embodiment, there is sodium phenolate in the reaction tower 5. In practice, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com