Method for deacidifying alpha-ethylli-nolenate solvent

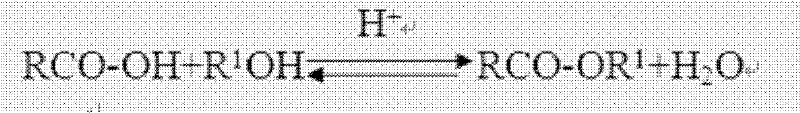

A technology of ethyl linolenate, esterification and deacidification, which is applied in the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds, etc., can solve the problems of low esterification rate, large amount of solvent and acidic catalyst, and achieve The effect of reducing acid value, reducing consumption and reducing discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Put 1000kg of α-ethyl linolenic acid with an acid value of 8 and 2000 kg of ethanol with a concentration of 80% into the reaction kettle, stir and mix evenly, let stand for 30 minutes, put the lower layer (α-linolenic acid ethyl ester layer) into the distillation In the kettle, distill under reduced pressure, reclaim ethanol, remove moisture to a moisture content of ≤0.1%, obtain 950 kg of ethyl α-linolenic acid product, and detect an acid value of 0.48;

[0031] Add 1 kg of concentrated sulfuric acid to the upper layer (free acid layer), heat up to 85°C, reflux for 6 hours, cool down to 30°C, wash with saturated brine until neutral, dehydrate under reduced pressure to 0.1% moisture, and obtain ethyl α-linolenic acid product 49.3kg, the detected acid value is 0.88.

Embodiment 2

[0033] Put 1000 kg of α-ethyl linolenic acid with an acid value of 8 and 500 kg of ethanol with a concentration of 95% into the reaction kettle, stir and mix evenly, let stand for 180 minutes, put the lower layer (α-linolenic acid ethyl ester layer) into the distillation In the kettle, distill under reduced pressure, reclaim ethanol, remove moisture until the moisture is 0.05%, and obtain 810kg of ethyl α-linolenic acid product, and the detected acid value is 0.26;

[0034] Add 5.7kg of concentrated sulfuric acid to the upper layer (free acid layer), heat up to 76°C, reflux for 1 hour, cool down to 35°C, wash with saturated brine until neutral, dehydrate under reduced pressure until the water content is 0.07%, and obtain α-linolenic acid ethyl The ester product was 189.3kg, and the detected acid value was 0.99.

Embodiment 3

[0036] Put 1000kg of α-linolenic acid ethyl ester with an acid value of 8 and 1000kg of ethanol with a concentration of 90% into the reaction kettle, stir and mix evenly, let stand for 90 minutes, put the lower layer (α-linolenic acid ethyl ester layer) into the distillation In the kettle, distill under reduced pressure, reclaim ethanol, remove moisture until the moisture is 0.08%, obtain 880kg of ethyl α-linolenic acid product, and detect the acid value as 0.35;

[0037] Add 3kg of sulfonic acid to the upper layer (free acid layer), raise the temperature to 80°C, reflux for 4h, wash with saturated brine until neutral, dehydrate under reduced pressure until the water content is 0.08%, and obtain 119.6kg of ethyl α-linolenic acid product. The acid value is 0.90.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com