Phenolphthalein polyaryletherketone and preparation method thereof

A technology of phenolphthalein polyaryletherketone and degree of polymerization, which is applied in the field of phenolphthalein polyaryletherketone and its preparation, can solve the problems of small application range of phenolphthalein polyaryletherketone, inability to regulate epoxy groups according to application requirements, etc. Application-wide effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

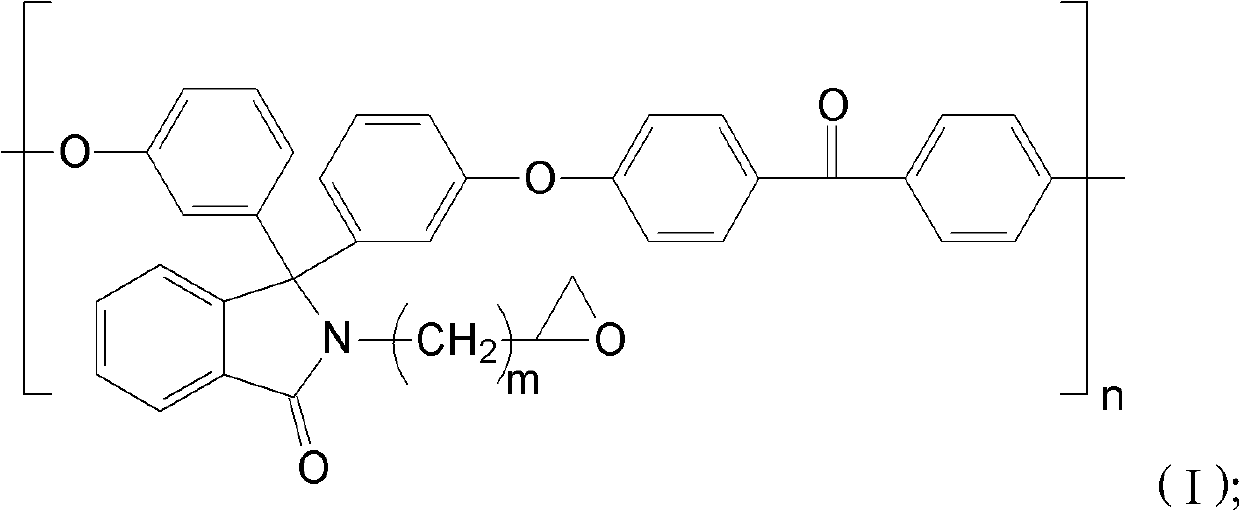

[0031] The present invention also provides a kind of preparation method of phenolphthalein polyaryletherketone, comprising the following steps:

[0032] Mixing the phenolphthalein polyarylether ketone having the structure of formula (II), catalyst, organic solvent and the epoxy haloalkane having the structure of formula (III), and reacting to obtain the phenolphthalein polyarylether ketone having the structure of formula (I);

[0033]

[0034]

[0035] Wherein, n is the degree of polymerization; 1≤m≤5; X is halogen.

[0036] In the present invention, under the protection of nitrogen, the phenolphthalein polyarylether ketone having the structure of formula (II), catalyst and organic solvent are added to the reactor, preferably at a temperature of 30°C to 50°C, more preferably at a temperature of 35°C to 45°C After stirring, preferably after 20min to 40min, more preferably 25min to 35min, the epoxy haloalkane with the structure of formula (III) is added, and the phenolphth...

Embodiment 1

[0059] Add 3.175g 3,3-bis(4-hydroxyphenyl)benzopyrrolone, 2.185g 4,4-difluorobenzophenone and 1.604 g potassium carbonate, stirred at a temperature of 120°C for 4h, then heated up to 130°C, continued to heat up to 145°C after a constant temperature of 1h, and stirred at a temperature of 145°C for 3h to obtain a phenolphthalein polyaryletherketone having a structure of formula (II) (PEK-IH), the yield is greater than 90%.

Embodiment 2

[0061] Put 0.486g PEK-IH and 0.104g NaH prepared in Example 1 into a three-neck flask with a thermometer, a nitrogen tube and a mechanical stirrer, add 18mL DMSO and stir at 30°C for 30min, then add 0.25mL epichlorohydrin , after reacting for 8 hours, the solution of the above reaction was poured into a beaker containing 50 mL of ethanol under vigorous stirring, and after filtering, it was repeatedly boiled and washed with deionized water, and after drying, a white phenolphthalein polyarylether ketone product was obtained, with a yield of 93 %.

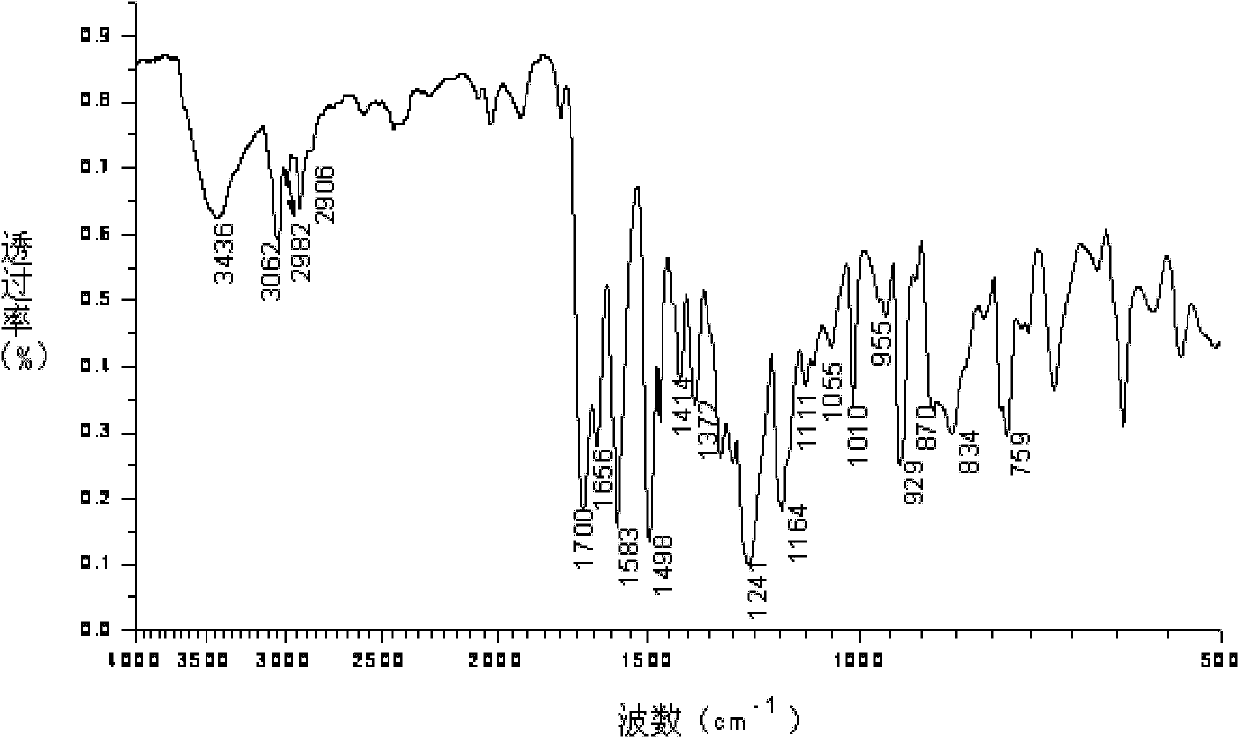

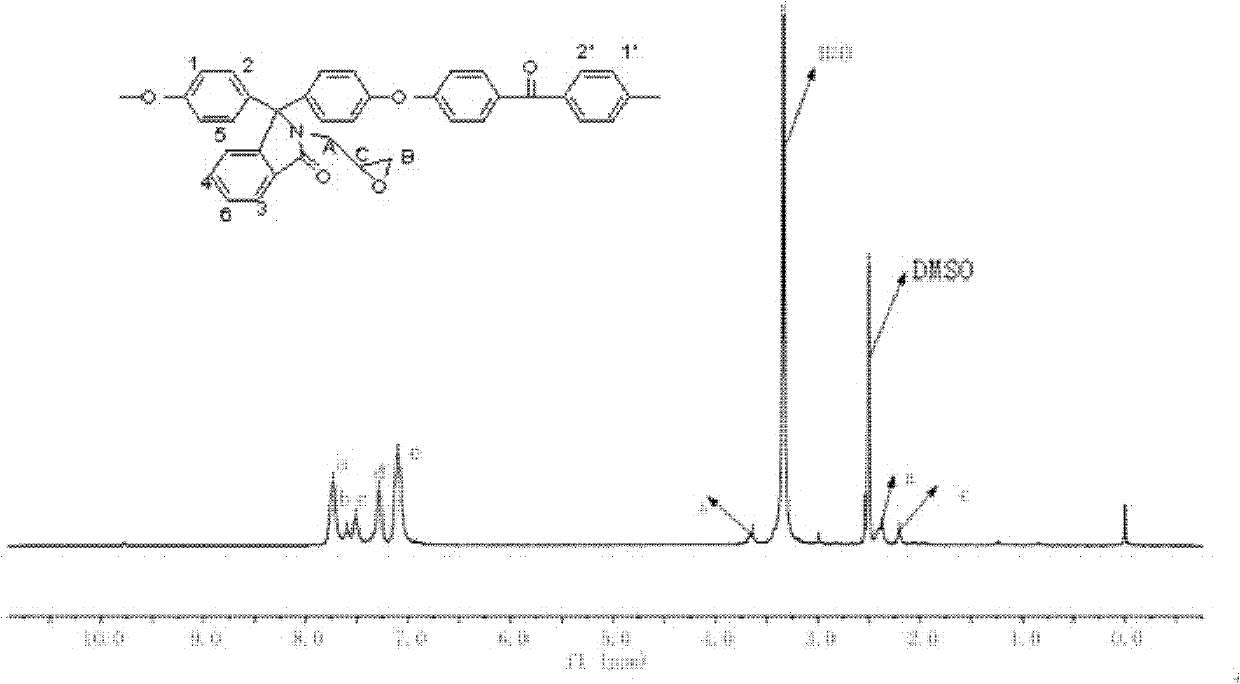

[0062] Gained white product is carried out infrared spectroscopic analysis, the result sees figure 1 , figure 1 It is the infrared spectrogram of the phenolphthalein polyaryletherketone obtained in Example 2 of the present invention. Depend on figure 1 It can be seen that the wave number is 3436cm -1 At the terminal phenolphthalein hydroxyl vibration peak, the wave number is 3062cm -1 The C-H stretching vibration peak on the benz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com