CMP (chemical mechanical polishing) liquid with high polishing rate for sapphire supporting base

A sapphire substrate, chemical-mechanical technology, applied in polishing compositions containing abrasives, etc., can solve the problems of low polishing rate and unsatisfactory surface quality, and achieve the effect of eliminating pits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

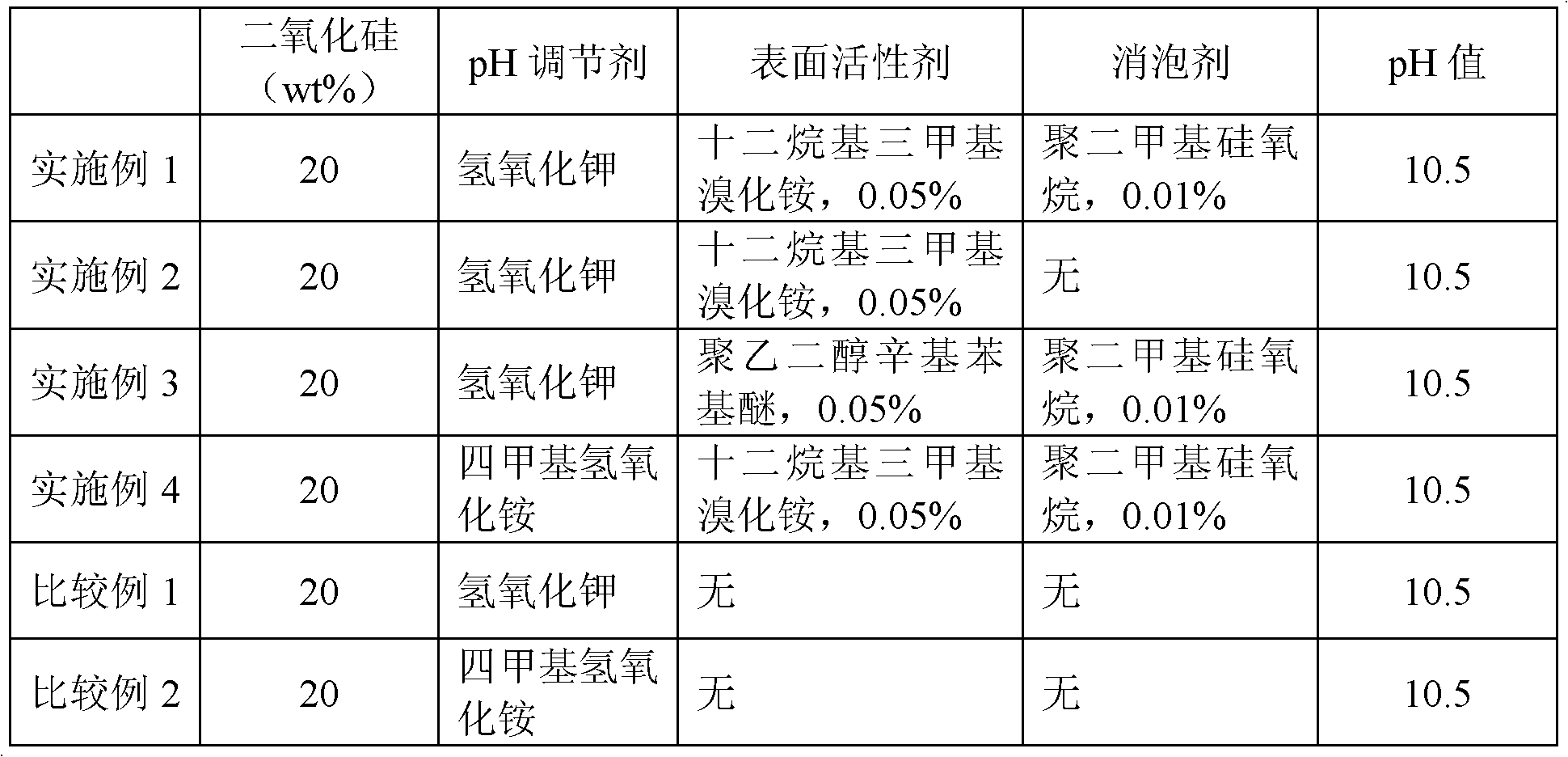

[0026] Under the condition of mechanical stirring, add the required amount of colloidal silicon dioxide into deionized water to disperse and dilute, then add pH regulator, surfactant, and defoamer in sequence, and stir well. The experimental samples of Examples 1-4 and Comparative Examples 1-2 were prepared by this method, and their specific proportions are shown in Table 1.

[0027] Table 1

[0028]

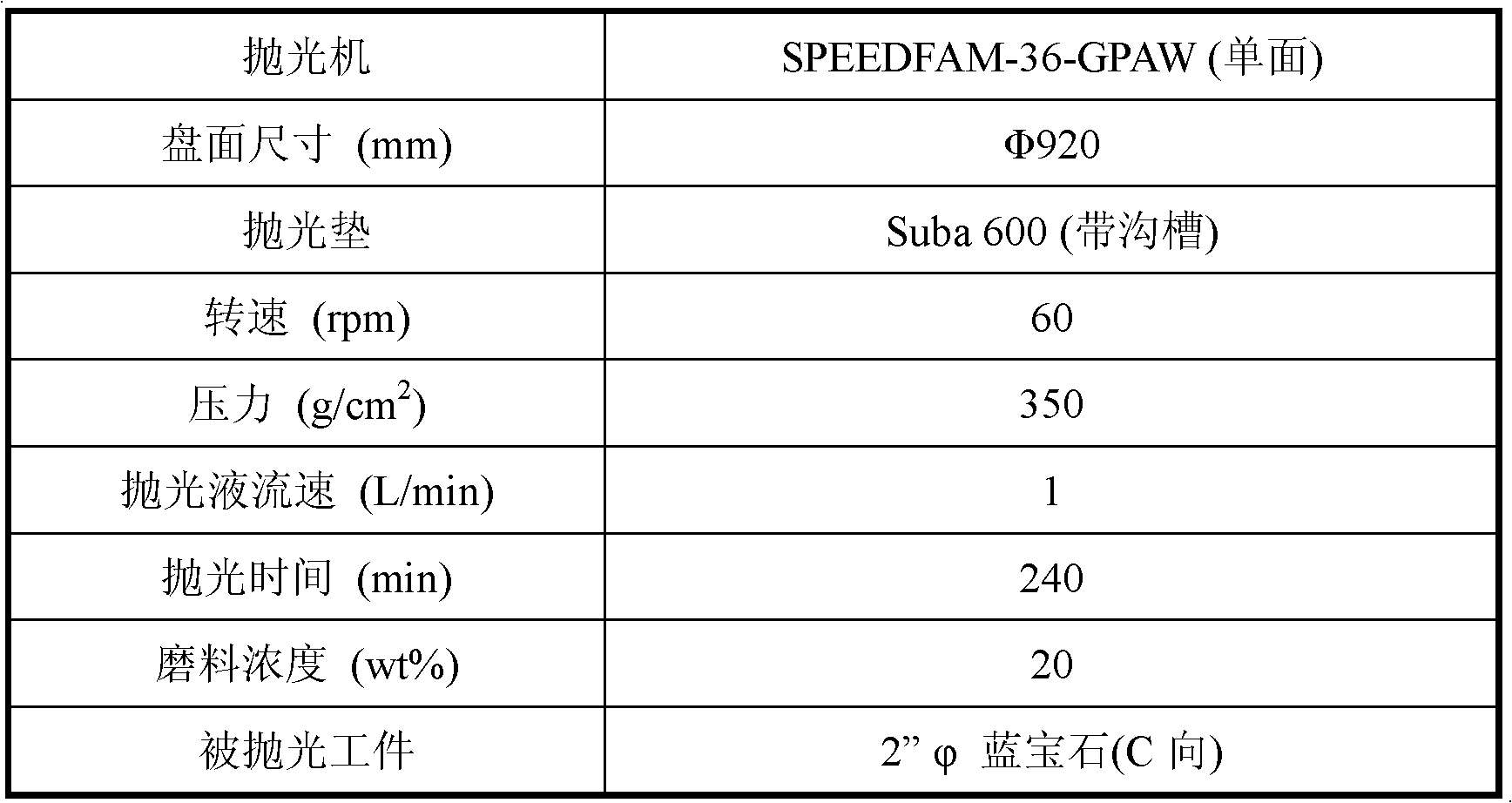

[0029] The polishing conditions for chemical mechanical polishing of the sapphire substrate using the above polishing solution are shown in Table 2:

[0030] Table 2

[0031]

[0032] After polishing, the sapphire substrate was washed and dried, and then the morphology and polishing rate of the substrate surface were measured. Use a spiral micrometer and a balance to measure the thickness difference and quality difference before and after polishing to evaluate the polishing rate, and use an atomic force microscope to measure the sapphire substrate to obtain the roughness...

Embodiment 5-7

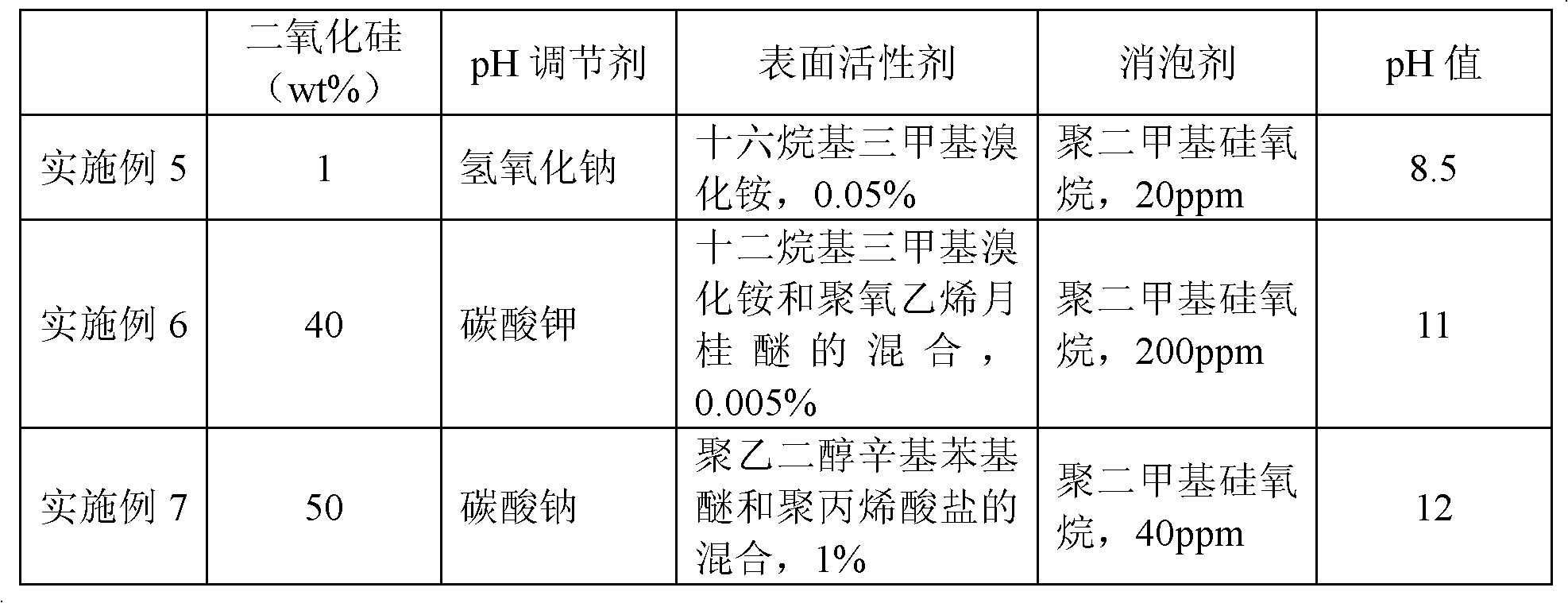

[0038] Under the condition of mechanical stirring, add the required amount of colloidal silicon dioxide into deionized water to disperse and dilute, then add pH regulator, surfactant, and defoamer in sequence, and stir well. The experimental samples of Examples 1-4 and Comparative Examples 1-2 were prepared by this method, and their specific proportions are shown in Table 4.

[0039] Table 4

[0040]

[0041] The sapphire substrate was chemically mechanically polished using the polishing solution of Examples 5-7. After polishing, the sapphire substrate was washed and dried, and then the morphology and polishing rate of the substrate surface were measured. Use a spiral micrometer and a balance to measure the thickness difference and quality difference before and after polishing to evaluate the polishing rate, and use an atomic force microscope to measure the sapphire substrate to obtain the roughness Ra value. The results obtained are shown in Table 5.

[0042] table 5

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com