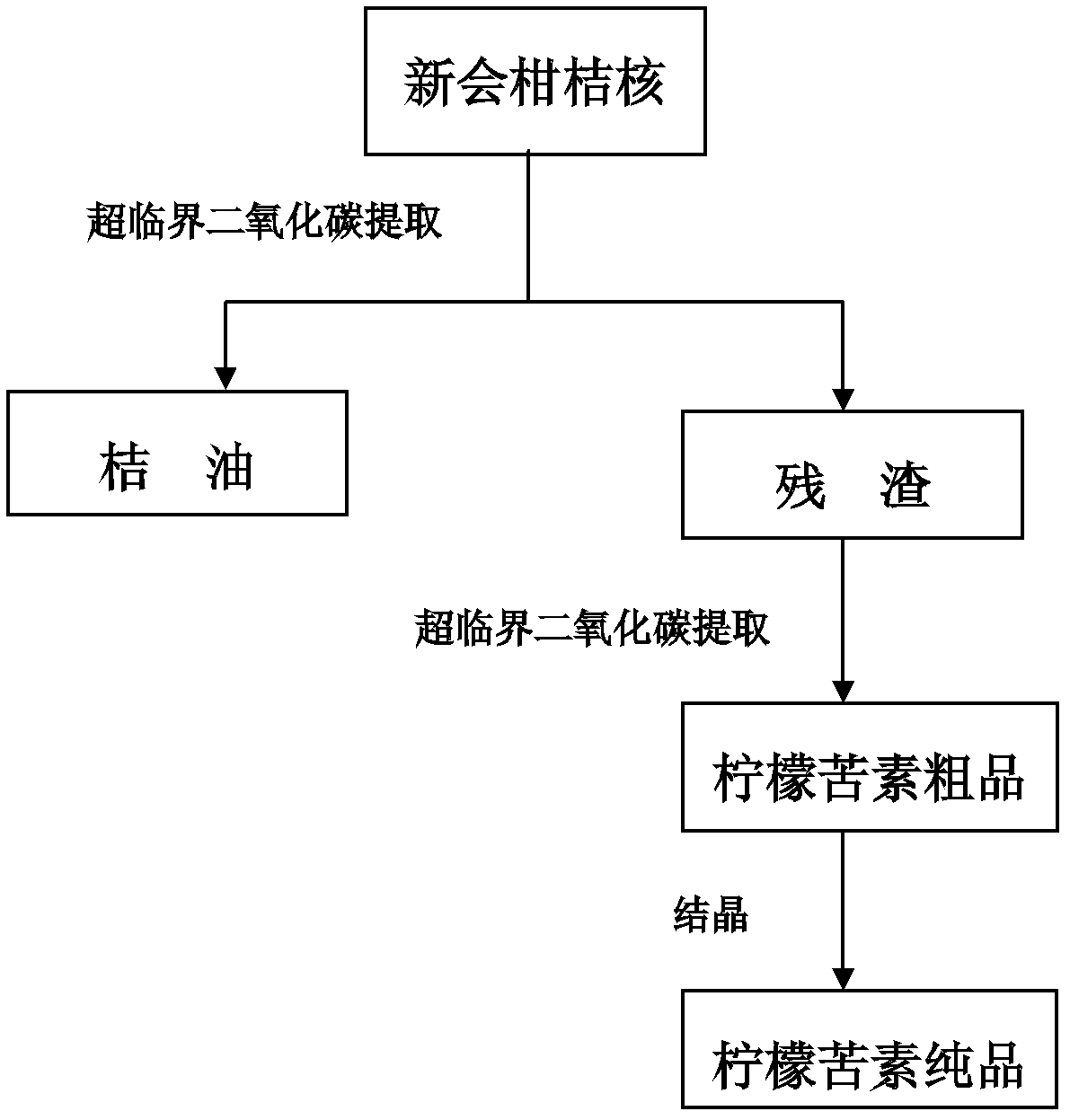

Method for continuously extracting orange oil and limonin from citrus reticulata

A technology of limonin and orange oil, which is applied in the production of fatty oil/fat, steroids, bulk chemicals, etc., can solve the problems of high production cost, limited popularization and application, etc., and achieve low production cost and high yield , oily yellowish effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

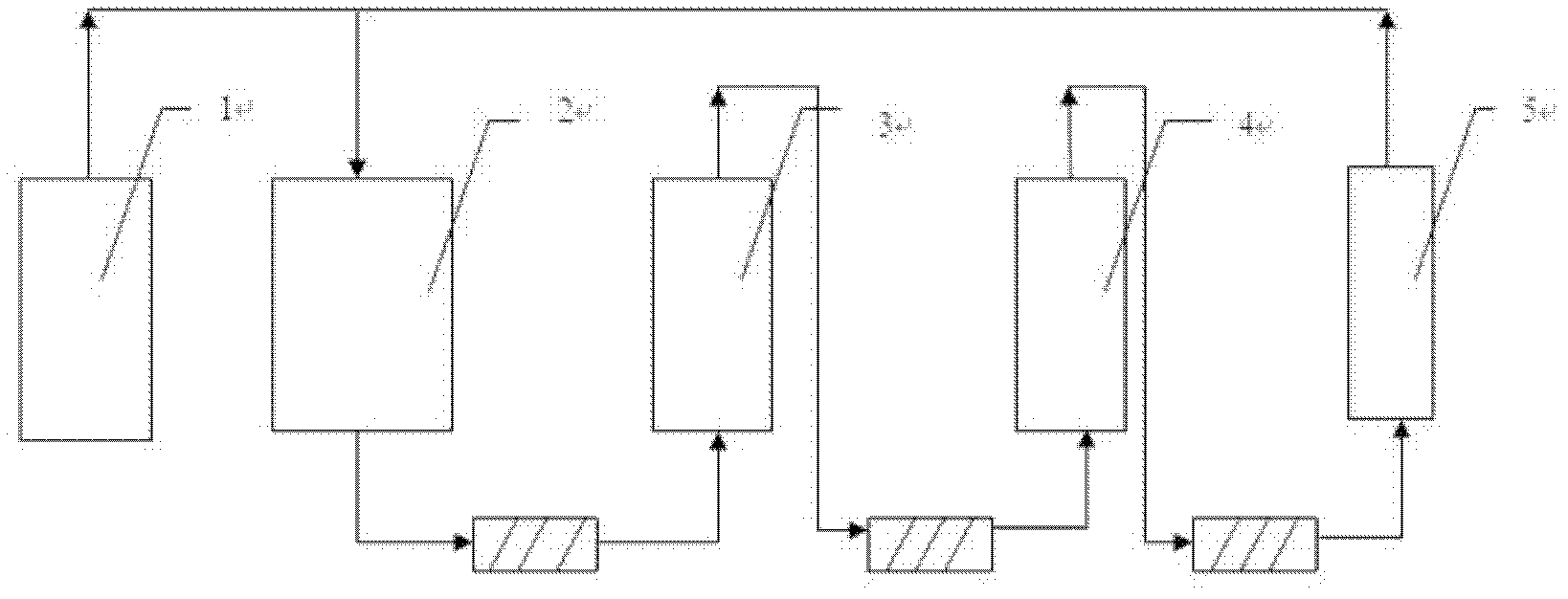

Method used

Image

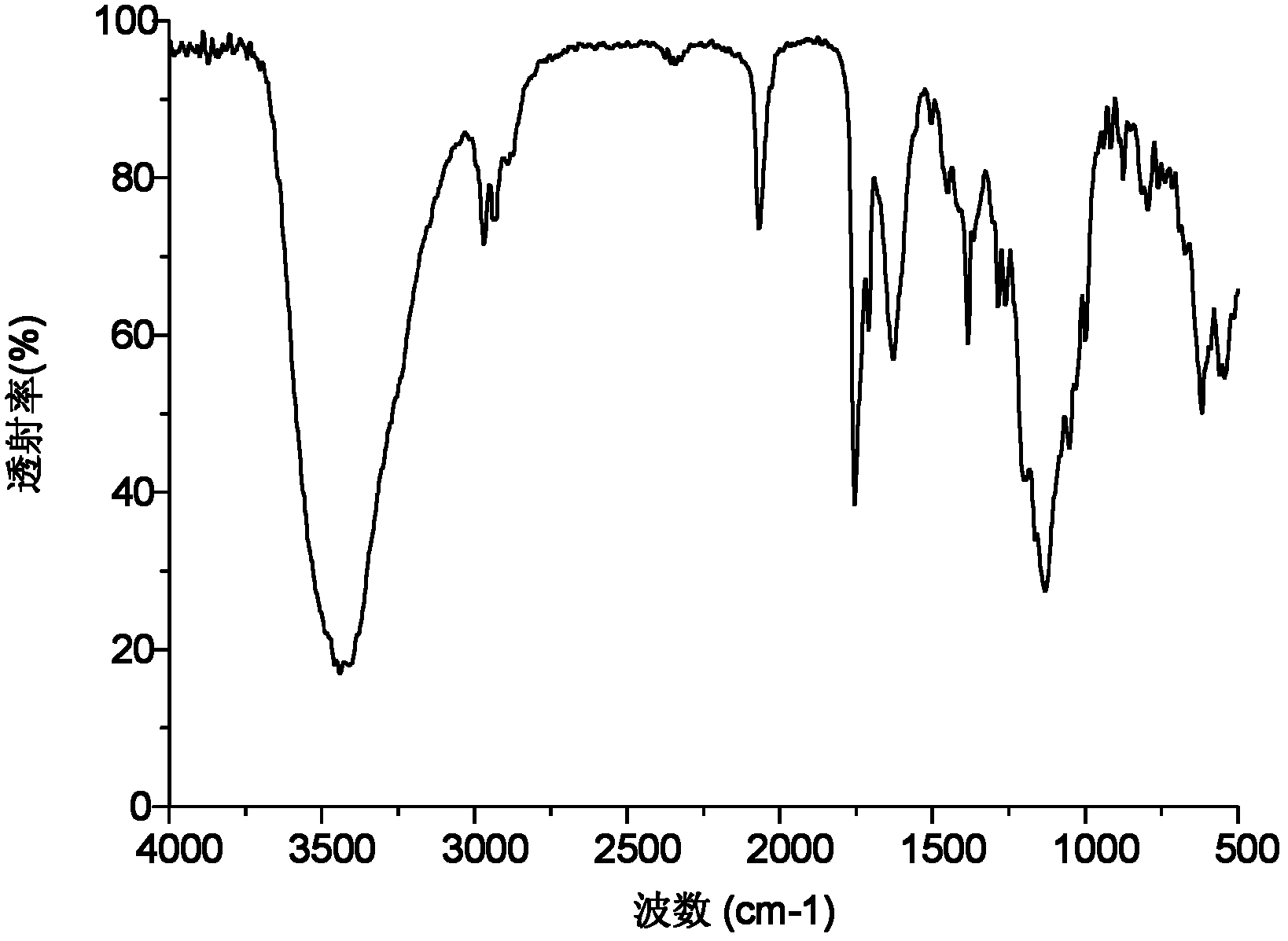

Examples

Embodiment 1

[0036] Apply the method provided by the invention to continuously extract tangerine oil and limonin from new citrus oranges, and the concrete steps are as follows:

[0037] The first step, the pretreatment of orange stone:

[0038] The core of Xinhui citrus was dried until the water content was about 3%, and it was pulverized to 40 mesh with a pulverizer.

[0039] The second step, the extraction of orange oil:

[0040] Get 300g of 40-mesh crushed material and pack it into the extraction tank. The flow rate of carbon dioxide is set as 60kg / h, the extraction pressure in the extraction tank is 28MPa, and the extraction temperature is 40°C to extract the orange oil.

[0041] The third step, the separation of orange oil:

[0042] The carbon dioxide carrying orange oil enters the separator for separation. The pressure of the primary separator is 12MPa, the temperature is 40°C MPa, the pressure of the secondary separator is 6MPa, and the temperature is 45°C.

[0043] Under the ex...

Embodiment 2

[0053] Apply the method provided by the invention to continuously extract tangerine oil and limonin from new citrus oranges, and the concrete steps are as follows:

[0054] The first step, the pretreatment of orange stone:

[0055] The Xinhui citrus core was dried until the water content was about 5 wt%, and it was pulverized to 50 mesh with a pulverizer.

[0056] The second step, the extraction of orange oil:

[0057] Get 400g of 50-mesh crushed material and put it into the extraction tank. The flow rate of carbon dioxide is set as 70kg / h, the extraction pressure in the extraction tank is 32MPa, and the extraction temperature is 45°C to extract the orange oil.

[0058] The third step, the separation of orange oil:

[0059] The carbon dioxide carrying orange oil enters the separator for separation. The pressure of the primary separator is 14MPa, the temperature is 50°C MPa, the pressure of the secondary separator is 7MPa, and the temperature is 50°C.

[0060] Operated unde...

Embodiment 3

[0070] Apply the method provided by the invention to continuously extract tangerine oil and limonin from new citrus oranges, and the concrete steps are as follows:

[0071] The first step, the pretreatment of orange stone:

[0072] The Xinhui citrus core was dried to a moisture content (mass percentage) of 9%, and it was pulverized to 60 mesh with a pulverizer.

[0073] The second step, the extraction of orange oil:

[0074] Get 500g of 60-mesh crushed material and put it into the extraction tank. The flow rate of carbon dioxide is set as 80kg / h, the extraction pressure in the extraction tank is 35MPa, and the extraction temperature is 50°C to extract the orange oil.

[0075] The third step, the separation of orange oil:

[0076] The carbon dioxide carrying orange oil enters the separator for separation. The pressure of the primary separator is 16MPa, the temperature is 50°C, the pressure of the secondary separator is 9MPa, and the temperature is 55°C.

[0077] Operated un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com