Primary dedusting system for rotating furnace

A dust removal system and converter technology, applied in the direction of manufacturing converters, improving process efficiency, improving energy efficiency, etc., can solve the problems of long maintenance time, excessive dust emission rate, high cost, etc., and achieve simple structure and low dust emission rate , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

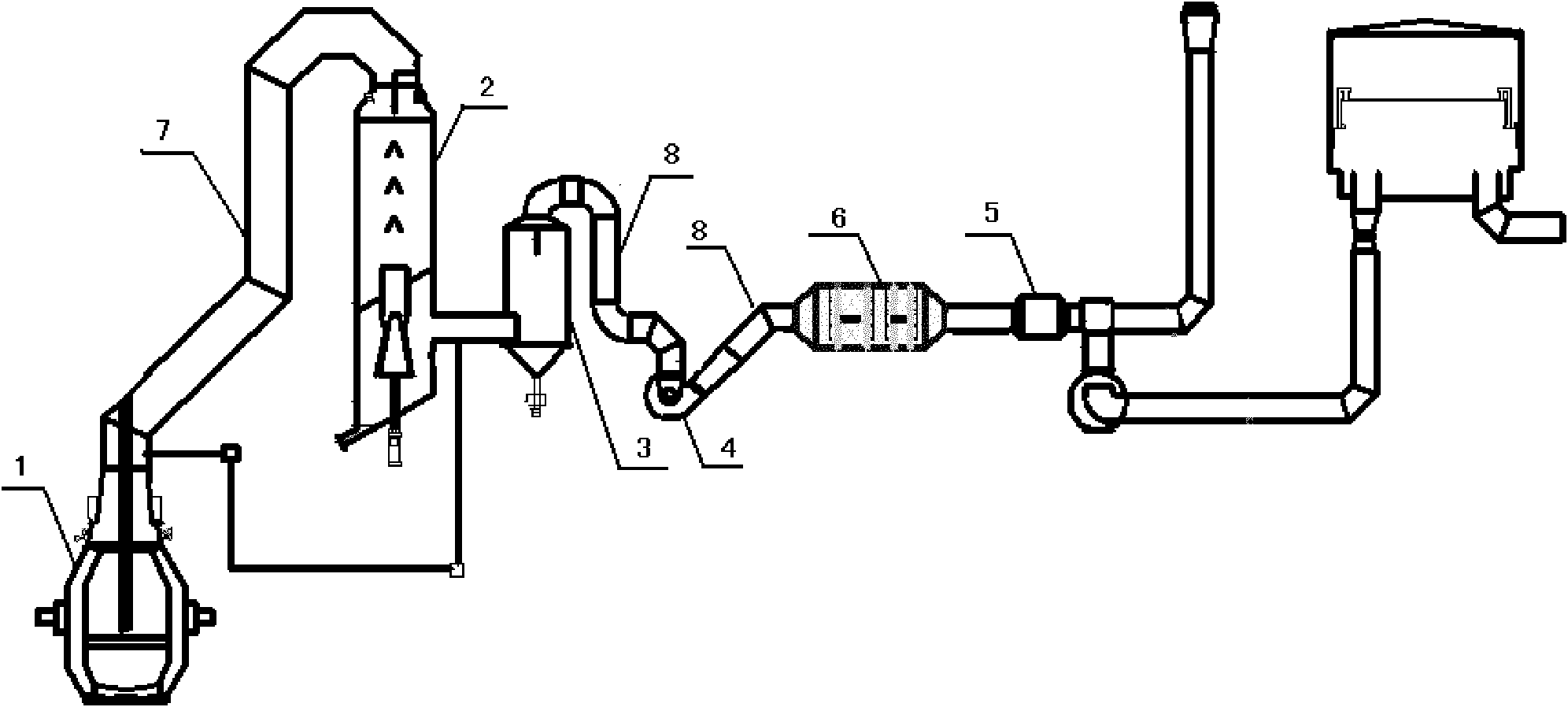

[0028] Such as figure 1 As shown, it is a structural schematic diagram of a primary dust removal system for a converter according to the present invention. The dust removal system includes a converter 1, a spray cooling tower 2, an annular seam washing tower 3, a dehydrator 4 and a fan 5. The gas in the converter 1 passes through the vaporization flue 7 to the spray cooling tower 2, and then passes through the gas in turn. The pipeline 8 leads to the ring seam washing tower 3, the dehydrator 4 and the fan 5, and the dust removal system also includes a dehumidifier 6, which is connected in series between the outlet of the dehydrator 4 and the inlet of the fan 5. Preferably, the dehumidifier is a cylindrical horizontal dehumidifier. This facilitates manufacture, installation and maintenance.

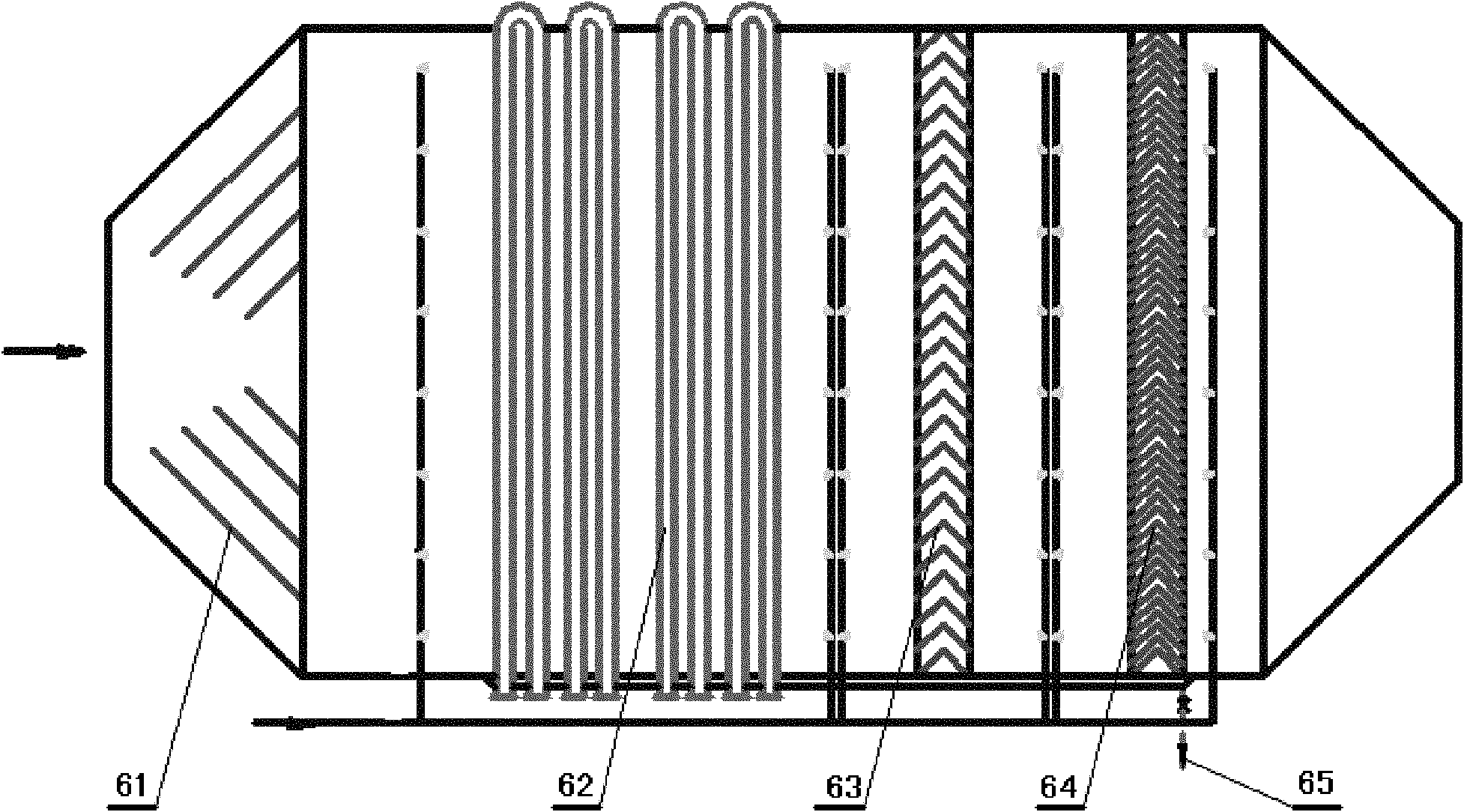

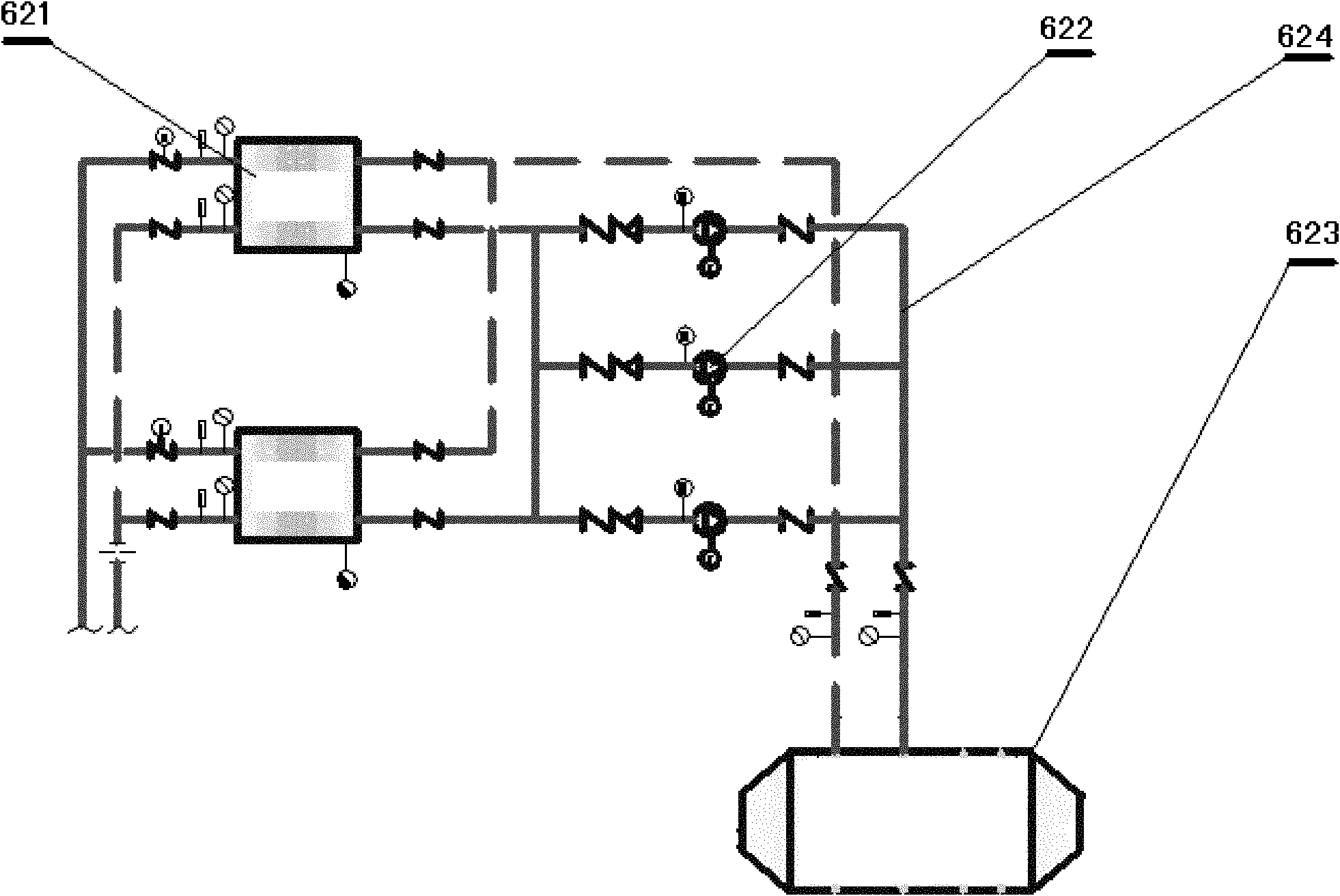

[0029] Such as figure 2 Shown is a schematic structural view of the dehumidifier in the dust removal system. The dehumidifier is provided with an inlet section, a condensation section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com