Manufacture method of target material structure

A production method and target technology, which are applied in metal material coating process, ion implantation plating, liquid chemical plating and other directions, can solve the problems of failing to meet the requirements of semiconductor targets, low bonding strength, etc., and achieve high bonding strength , to achieve the effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The production of existing molybdenum or molybdenum alloy target components is to directly weld molybdenum or molybdenum alloy and dissimilar metal (such as copper, copper alloy, aluminum or aluminum alloy) back plate, which will cause unstable welding quality of the two (such as welding combination The strength is weak), which cannot meet the requirements of semiconductor targets.

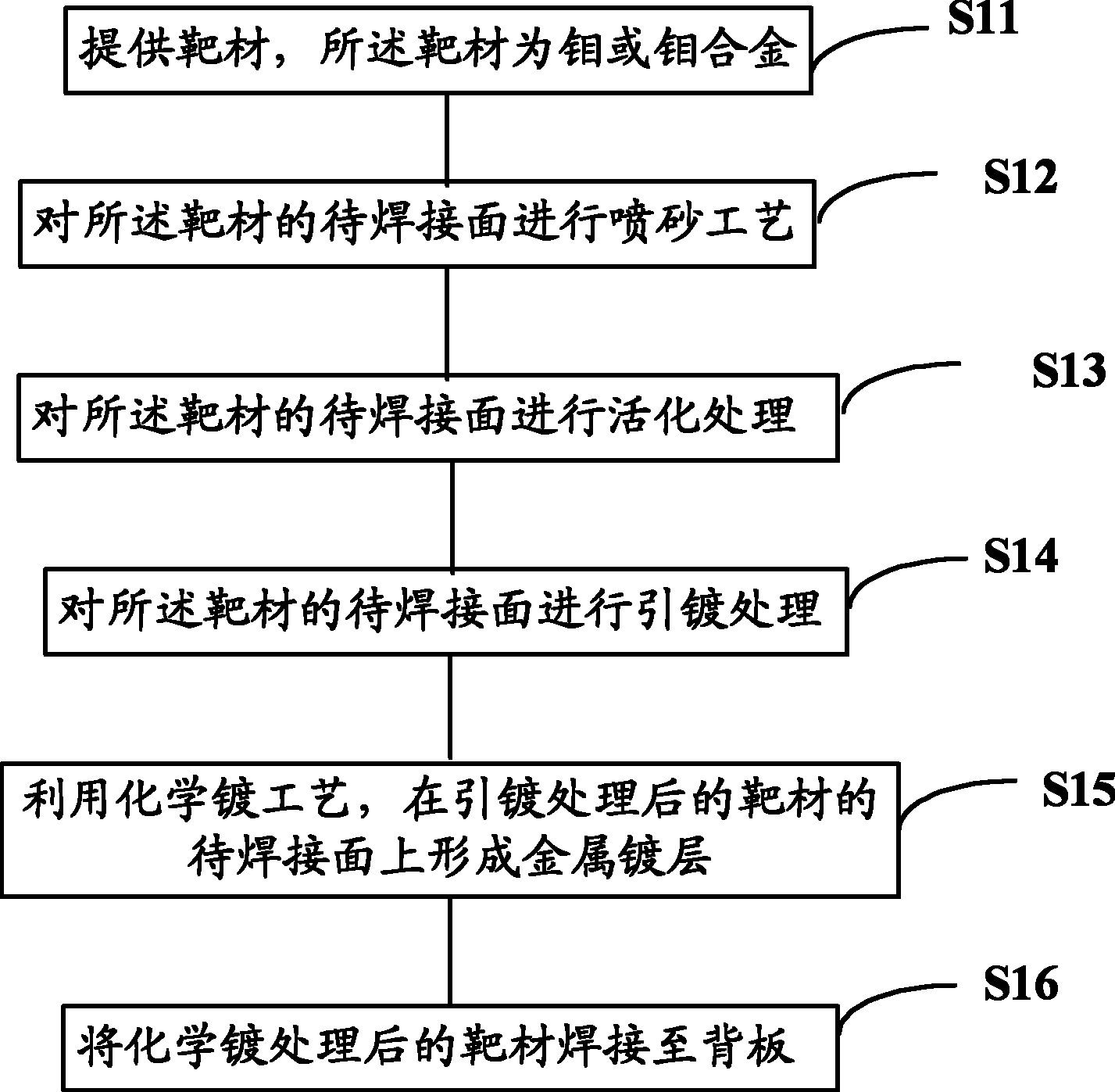

[0039] An embodiment of the present invention provides a method for manufacturing a target assembly, figure 1 It is a schematic flow chart of manufacturing a target structure according to an embodiment of the present invention. Such as figure 1 as shown,

[0040] Step S11, providing a target material, the target material is molybdenum or molybdenum alloy;

[0041] Step S12, performing a sandblasting process on the surface of the target to be welded;

[0042] Step S13, performing activation treatment on the surface to be welded of the target;

[0043] Step S14, performing induction plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com