Kapok spinning processing method

A processing method and kapok spinning technology, which is applied in yarn, textiles, papermaking, plant fibers, etc., can solve the problems of high discreteness of kapok fibers, difficulty in spinning, and inability to separate the lengths of kapok fibers, etc., and achieve the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is applied in the modern spinning process system, and is an improvement on the basis of existing kapok weaving which is difficult to spin due to the influence of kapok's own characteristics in practical application.

[0022] The technical problem to be solved by the present invention is to provide a kapok blended processing method and its production process.

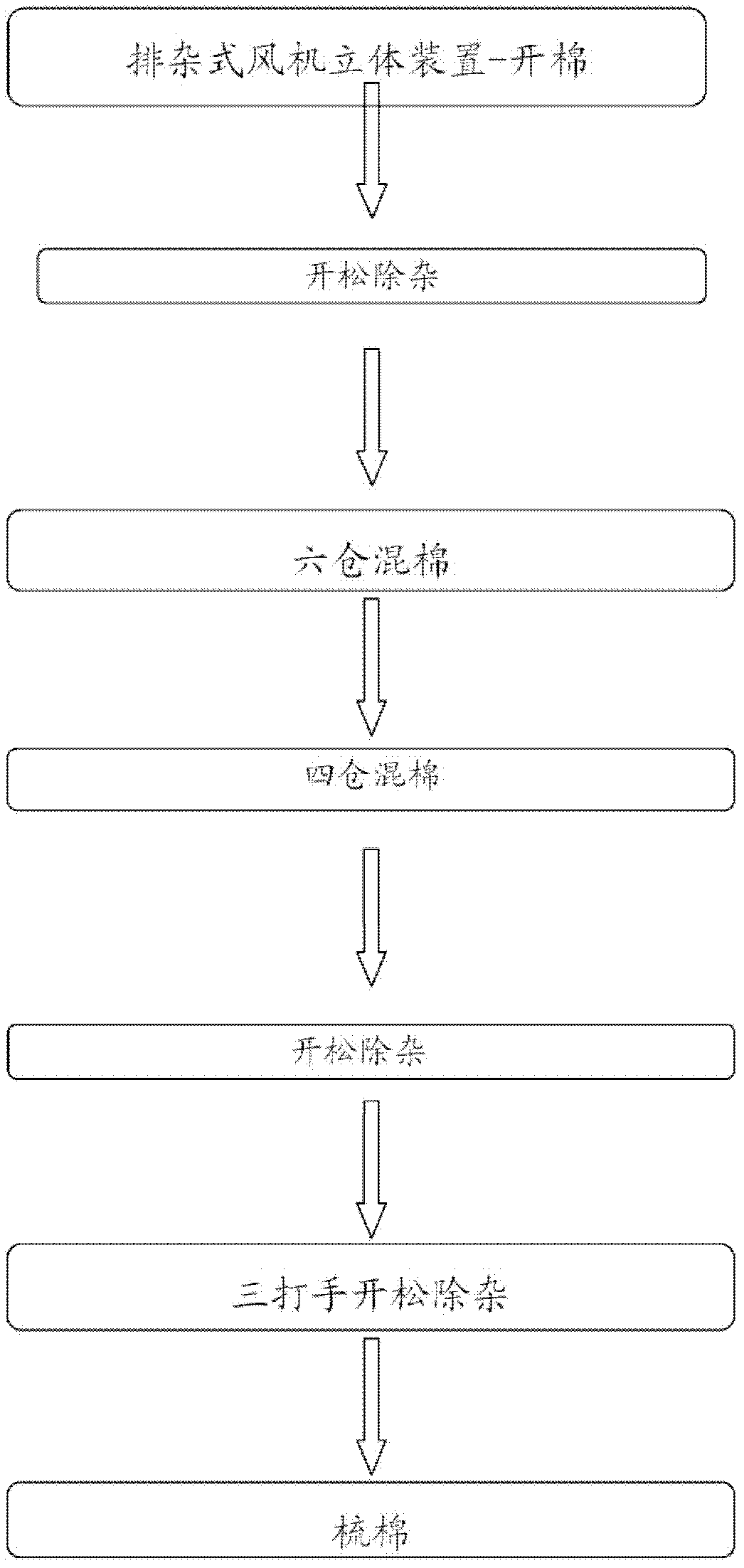

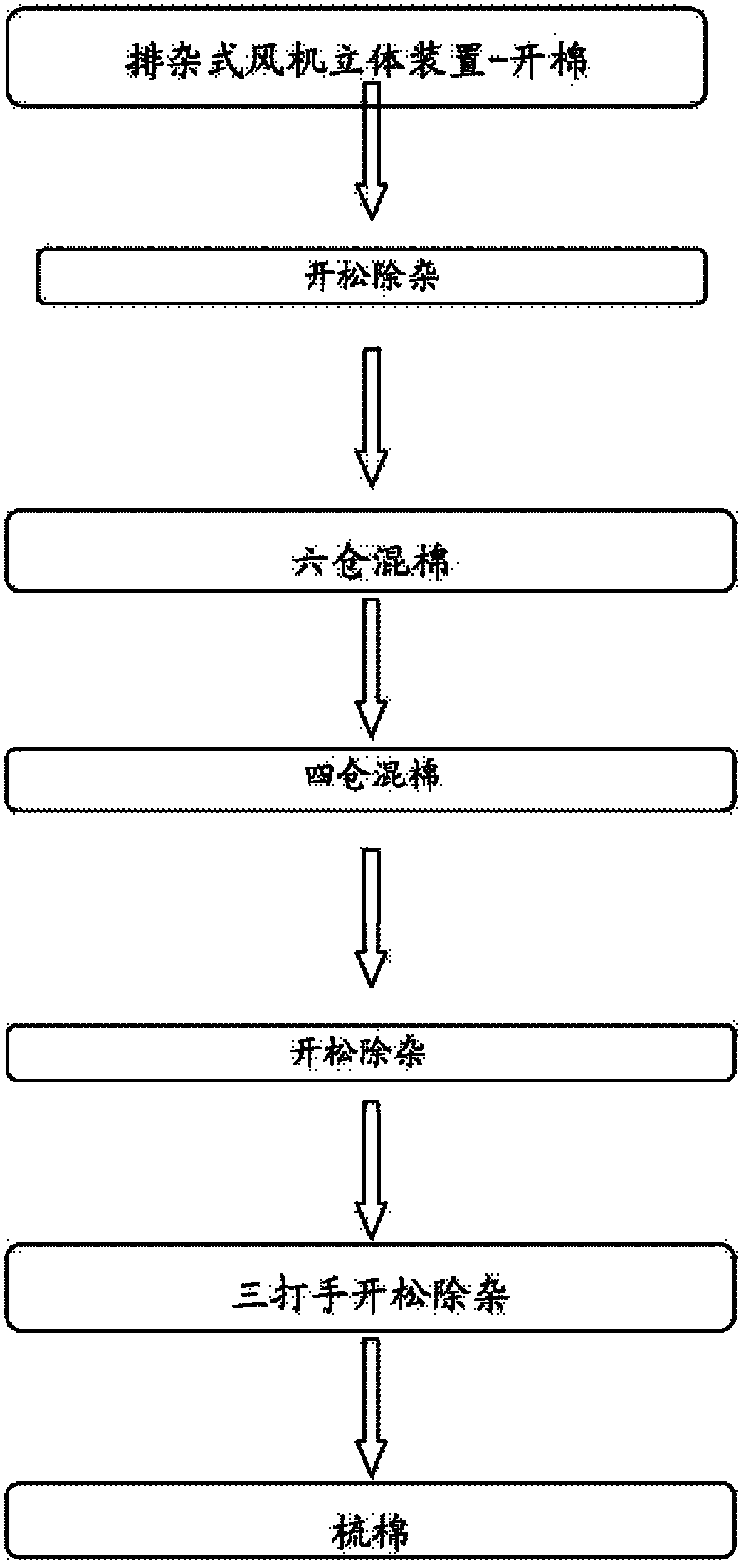

[0023] As shown in the figure, the processing method of the present invention comprises the following steps:

[0024] 1. Humidify the kapok fiber with steam, and add non-ionic additives at the same time. The non-ionic additives include but not limited to: 1), auxiliary agent: polyethylene glycol; 2), starch: triethanolamine.

[0025] 2. Saponification value 90-160, its PH value: 6-7

[0026] 3. Kapok treatment: The above-mentioned non-ionic additives are added in the process of loosening and smoothing the kapok by the miscellaneous fan three-dimensional device.

[0027] 4. Then enter the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com