Waterproof thermal-insulation decorative wall board, casing for doors and windows, and installation method of casing

A thermal insulation decorative board, waterproof technology, applied in the direction of window/door frame, covering/lining, construction, etc., can solve the problems of difficult construction, poor sealing performance, poor fixation, etc., to reduce labor intensity and labor volume , Improve the firmness and stability, the effect of firm combination and elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

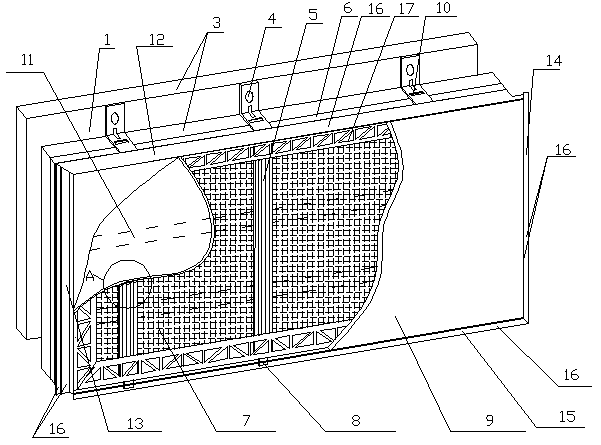

[0049] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0050] The technical solution of the present invention is: a waterproof wall thermal insulation decorative board, including a thermal insulation laminate and a structural laminate, the structural laminate covers the thermal insulation laminate, and the thermal insulation layer is fixed on the structural laminate through the structural laminate On the wall; use the integrity of the structural laminate, that is, strength and rigidity, and use a certain method to fix the insulation layer on the wall.

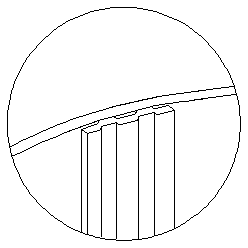

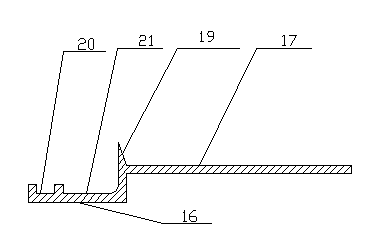

[0051] from figure 1 It can be seen that the waterproof wall thermal insulation decorative panel includes the thermal insulation laminate 3, the thermal insulation laminate 3 is two upper and lower layers arranged in dislocation, and the upper surface of the thermal insulation laminate 3 is sequentially covered with the structural laminate 6 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com