Design method of blade suction surface groove for controlling flow separation

A suction surface and blade technology, applied to blade support components, mechanical equipment, engine components, etc., to achieve the effects of improving flow conditions, reducing fuel consumption, increasing efficiency and total pressure recovery coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

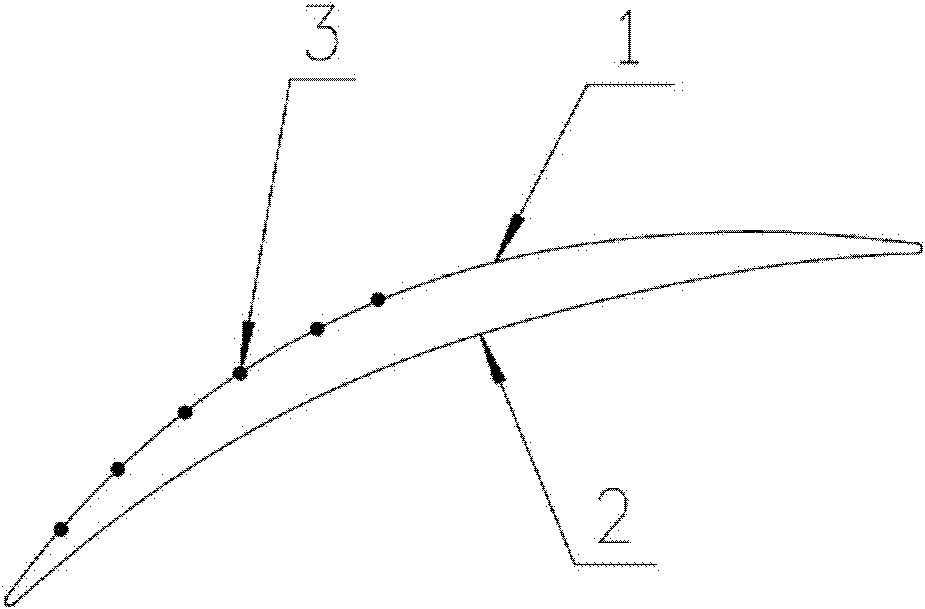

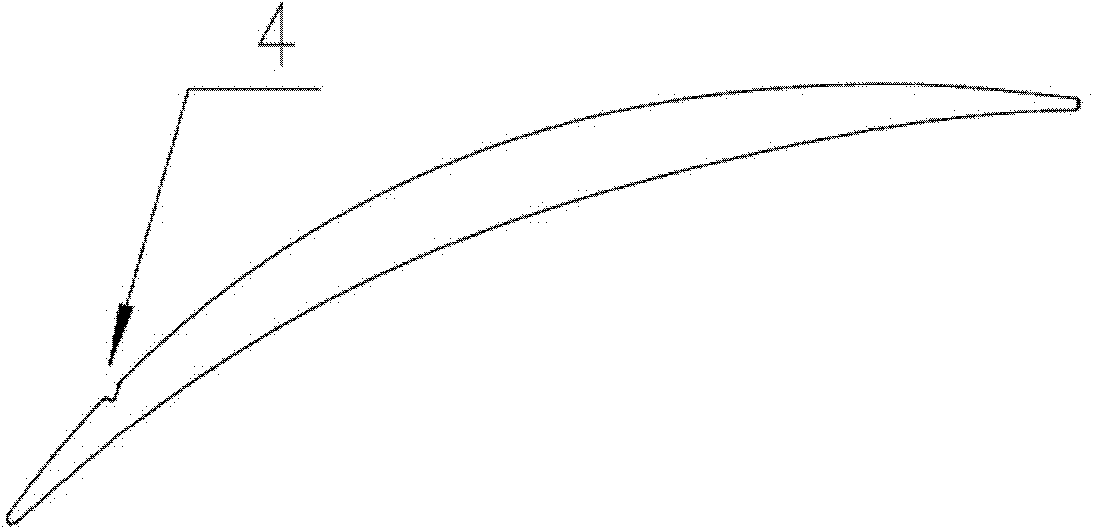

[0026] In this embodiment, a certain cascade primitive blade type (as attached Figure 5 shown) is the design object. The design inlet Mach number of this primitive airfoil is 0.7, and the critical angle of attack is 8°. To design the groove 4 on the blade suction surface 1 of the original primitive airfoil shape, it is first necessary to determine the initial position of the groove starting point, the initial projected length of the groove on the blade suction surface profile line, and the initial curve describing the groove function equation.

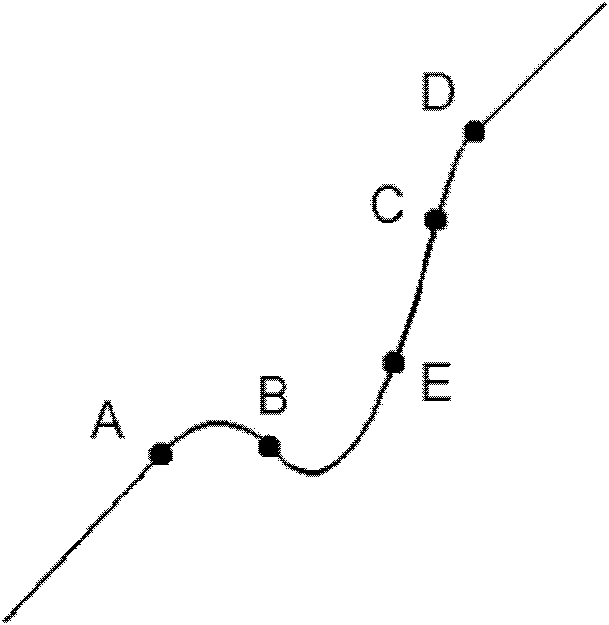

[0027] To determine the initial position of the starting point of the groove, it is necessary to calculate and analyze the flow field of the original primitive blade type cascade channel. The initial position of the starting point of the groove is selected within the projection range of the development stage of the separation zone on the suction surface of the blade, and the projection range of the development stage of the separatio...

Embodiment 2

[0038] In this embodiment, a certain cascade primitive blade shape is taken as the design object. The design inlet Mach number of the primitive airfoil is 0.5, and the critical angle of attack is 8°. To design the groove on the blade suction surface of the original primitive airfoil shape, it is first necessary to determine the initial position of the groove starting point, the initial projection length of the groove on the blade suction surface shape line, and the initial function equation describing the groove curve .

[0039] To determine the initial position of the starting point of the groove, it is necessary to calculate and analyze the flow field of the original primitive blade type cascade channel. The initial position of the starting point of the groove is selected within the projection range of the development stage of the separation zone on the suction surface of the blade, and the projection range of the development stage of the separation zone on the suction surf...

Embodiment 3

[0050] In this embodiment, a certain cascade primitive blade shape is taken as the design object. The design inlet Mach number of the basic airfoil is 0.6, and the critical angle of attack is 7°. To design the groove on the blade suction surface of the original primitive airfoil shape, it is first necessary to determine the initial position of the groove starting point, the initial projection length of the groove on the blade suction surface shape line, and the initial function equation describing the groove curve .

[0051] To determine the initial position of the starting point of the groove, it is necessary to calculate and analyze the flow field of the original primitive blade type cascade channel. The initial position of the starting point of the groove is selected within the projection range of the development stage of the separation zone on the suction surface of the blade, and the projection range of the development stage of the separation zone on the suction surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com