Cement kiln tube body cooling automatic control system

An automatic control system and control system technology, applied in the direction of furnaces, lighting and heating equipment, furnace types, etc., can solve the problems of reducing the quality and output of cement clinker, increasing the maintenance of kiln shells, and falling off of refractory bricks on the inner wall of the kiln, etc. Achieve the effect of reducing maintenance, preventing local overheating and reducing danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

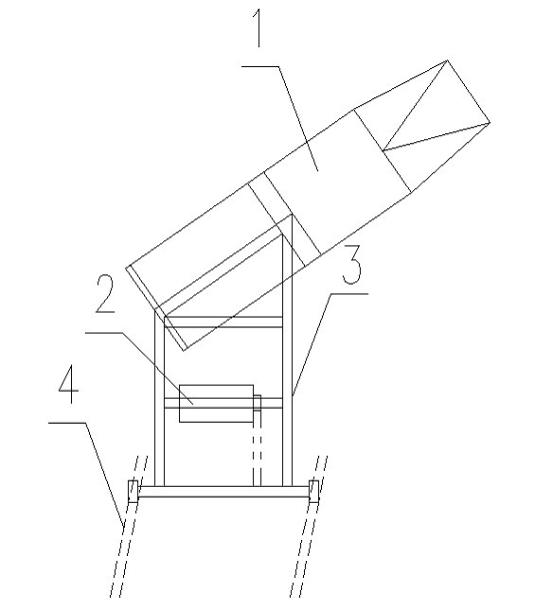

[0014] In the figure, a track 4 is laid on one side of the cement kiln. The track 4 is parallel to the kiln body. The fan 1 is fixed on the trolley frame 3 at a certain angle. The trolley frame 3 can ride on the track 4 through its four wheels. Parallel rolling; a transmission device 2 is installed on the trolley frame 3, the transmission device 2 is composed of a motor, a coupling and a reducer, and the transmission device 2 can drive the fan 1 to freely parallel on the track 4 by driving the wheels of the mobile. The number of fans 1 is determined according to the scale of the on-site cement kiln.

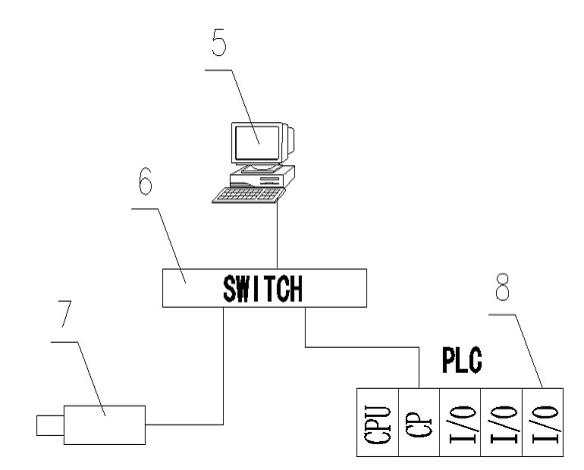

[0015] The start and stop signals of the fan 1 are introduced into the computer control system 5 through the programmable controller PLC8, and the forward and reverse signals of the motor of the wheel transmission device 2 of the trolley frame 3 are introduced into the computer control system 5; the kiln body infrared scanner system 7 Communicate with the computer control system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com