Method for estimating endurance life of vehicle motor driving system

A technology of motor drive system and durability life, which is applied in the direction of engine testing, machine/structural component testing, measuring devices, etc., to achieve the effect of reducing test cost, reducing test time and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will be clearly and completely described in conjunction with the drawings of the technical solutions in the embodiments of the present invention. All other embodiments obtained by those of ordinary skill in the art without creative work fall within the protection scope of the present invention .

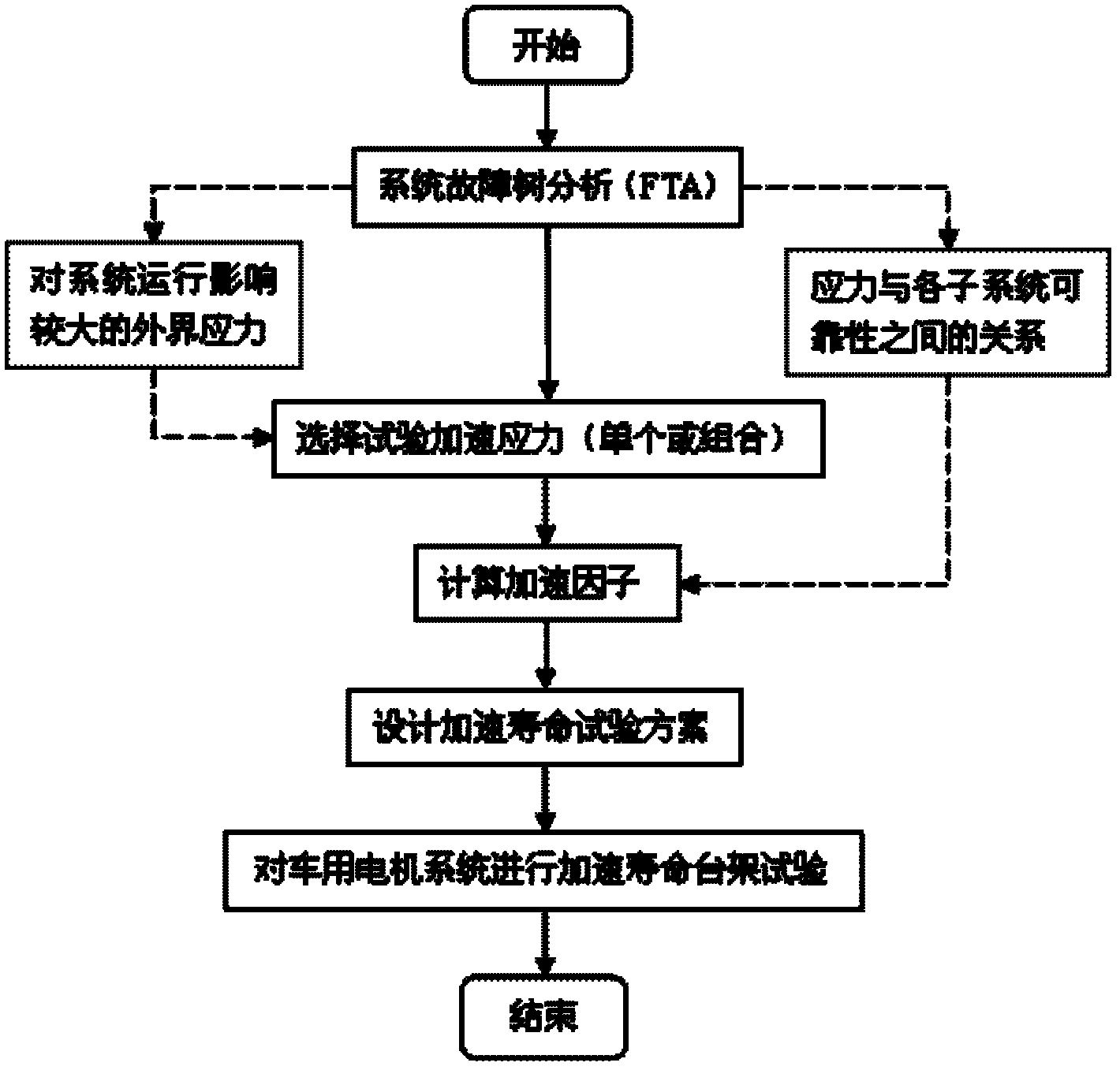

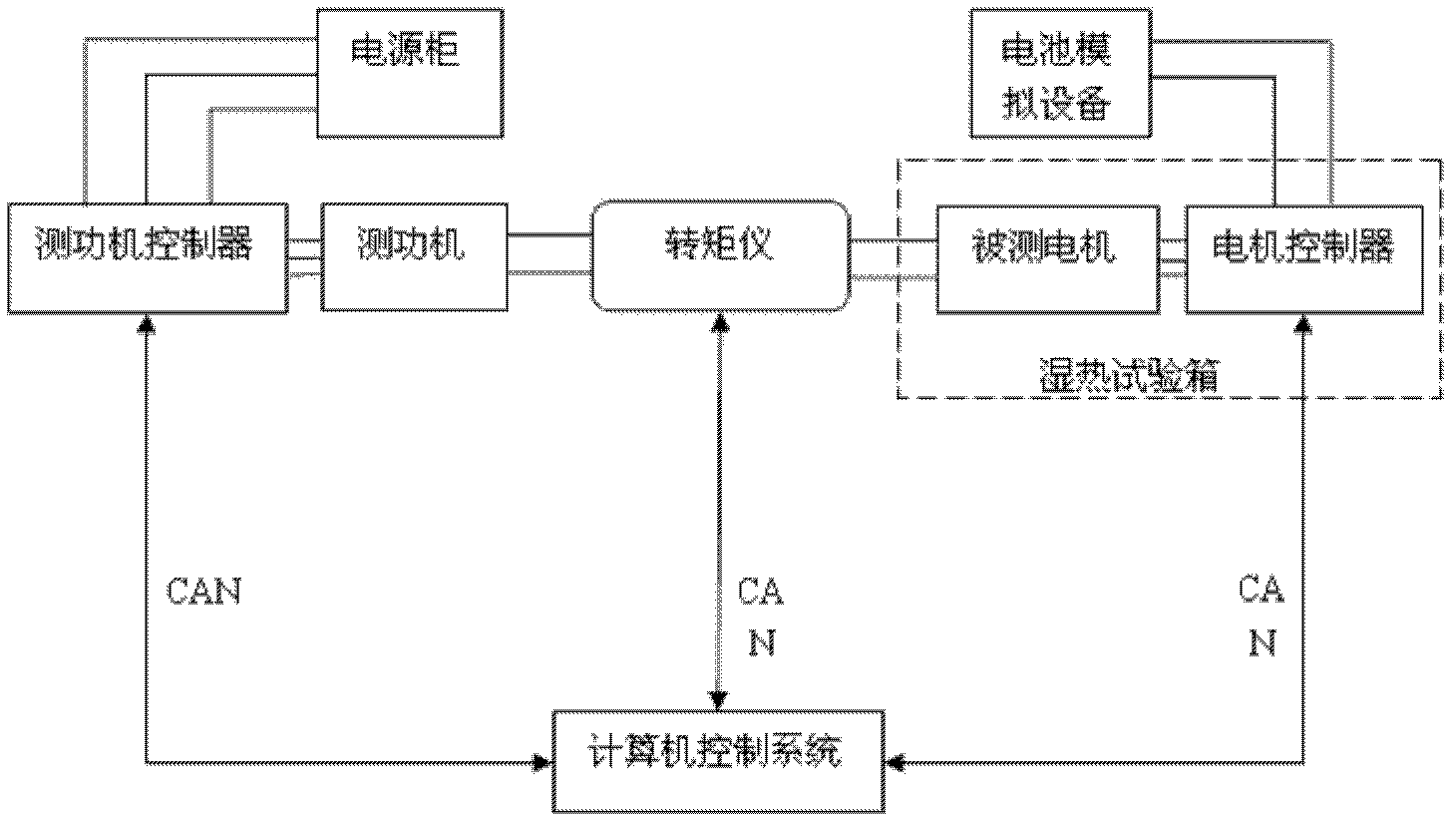

[0030]The flow chart of the accelerated life test method of the vehicle motor system of the present invention is as follows figure 1 As shown, its specific implementation is as follows:

[0031] To determine the reliability index of the vehicle motor system, the present invention uses the system mean working time before failure (MTTF) and mean time between failure (MTBF) to measure the reliability of the system.

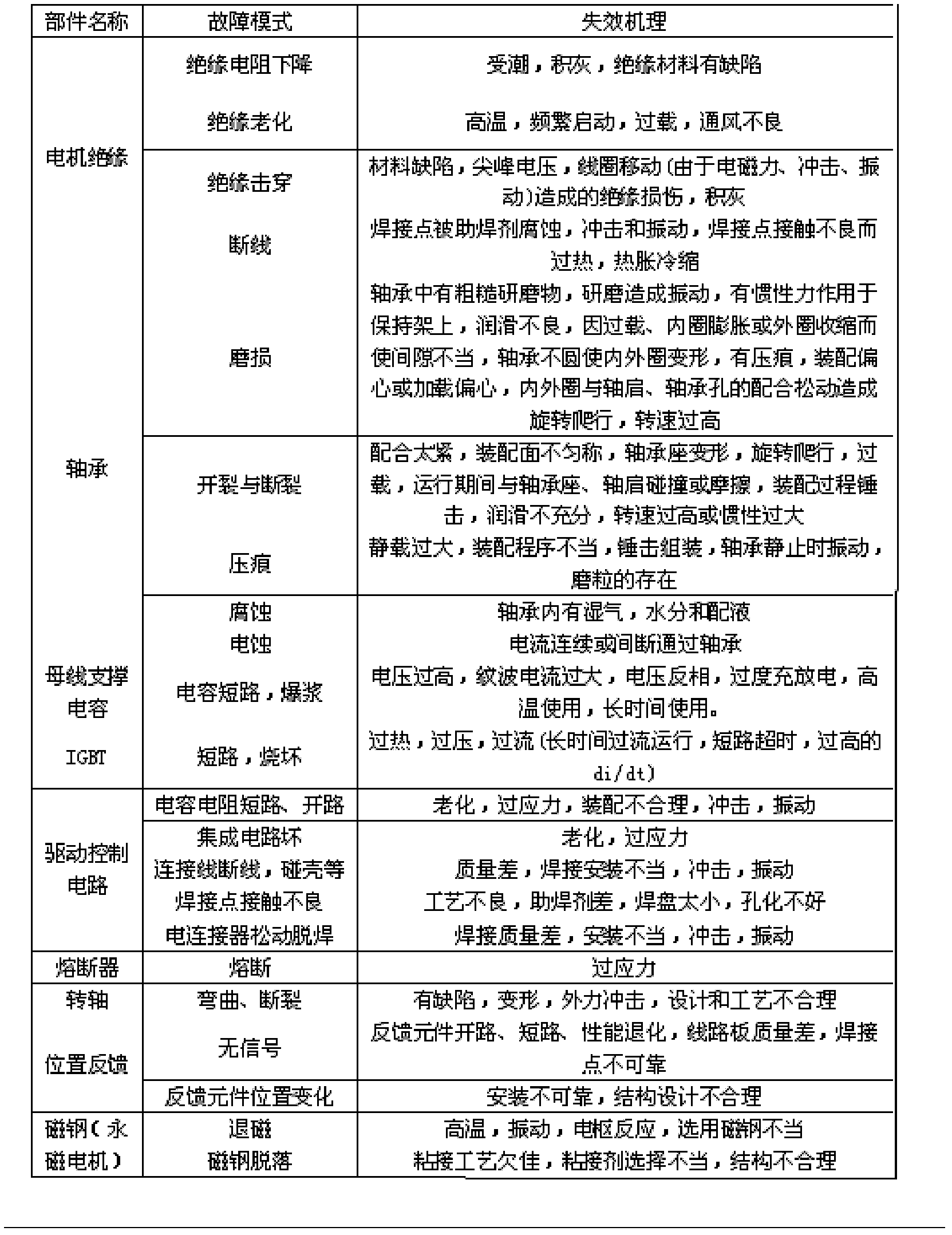

[0032] Analyze the failure mode and failure mechanism of weak links in the system (motor insulation, bearings, bus support capacitors, IGBT, control circuit, magnetic steel), and select the controller output voltage and current value, motor speed and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com