Ultrasonic excitation impact space sampling drill

An ultrasonic excitation, space technology, applied in the direction of sampling devices, etc., can solve problems such as differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

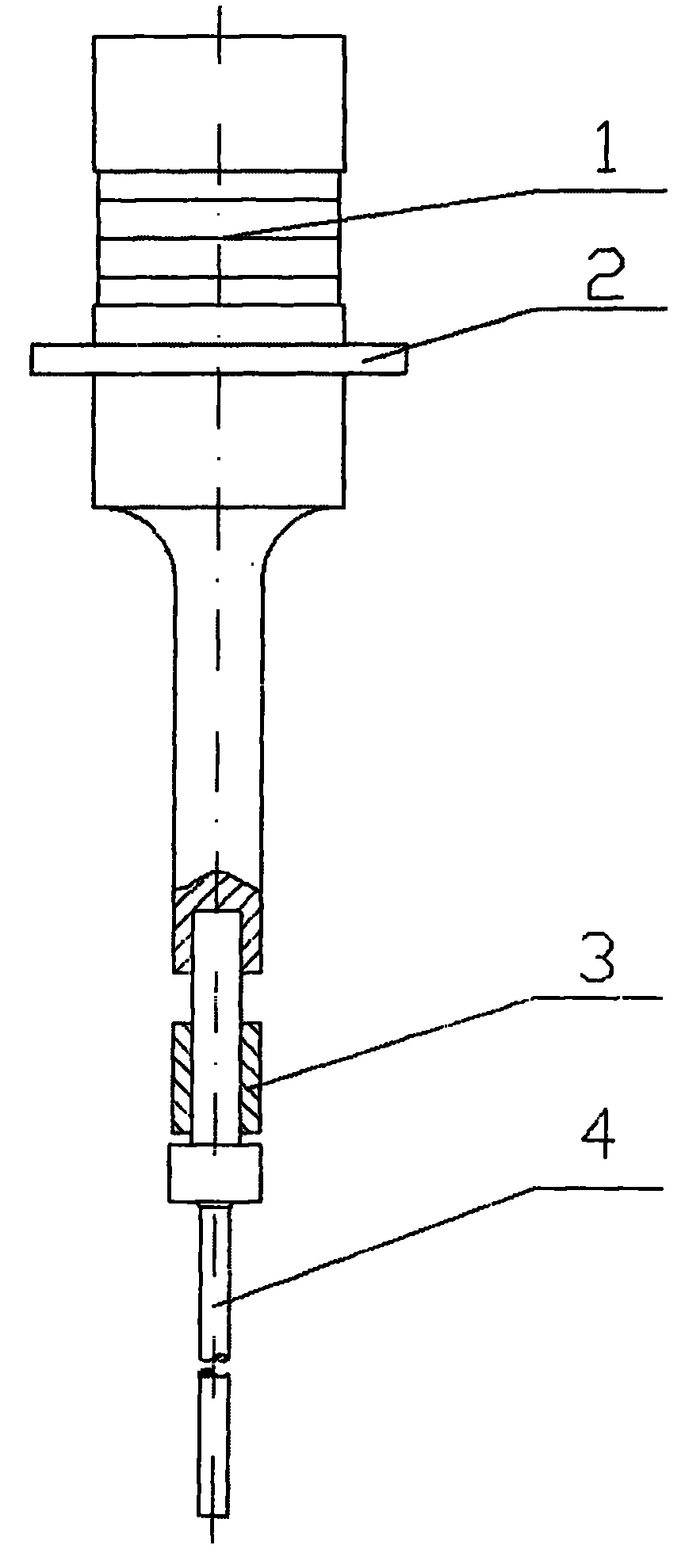

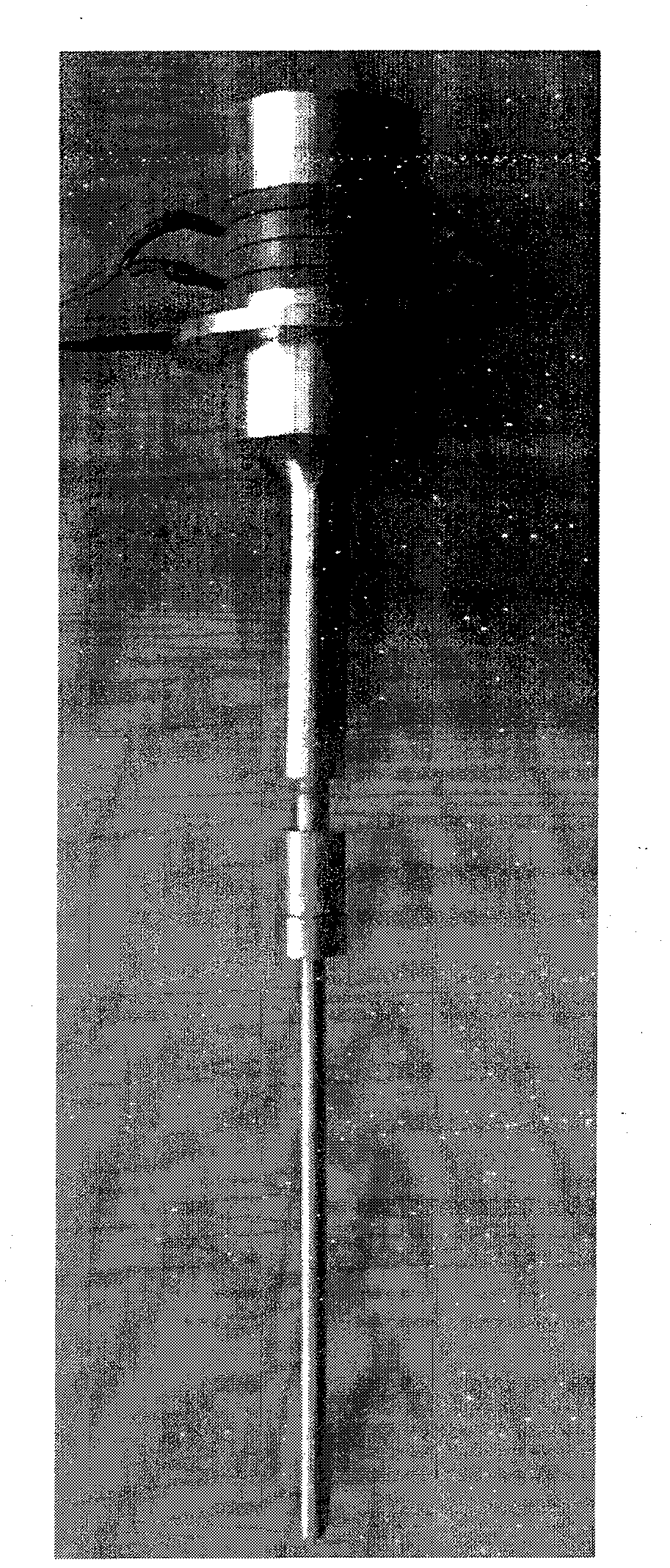

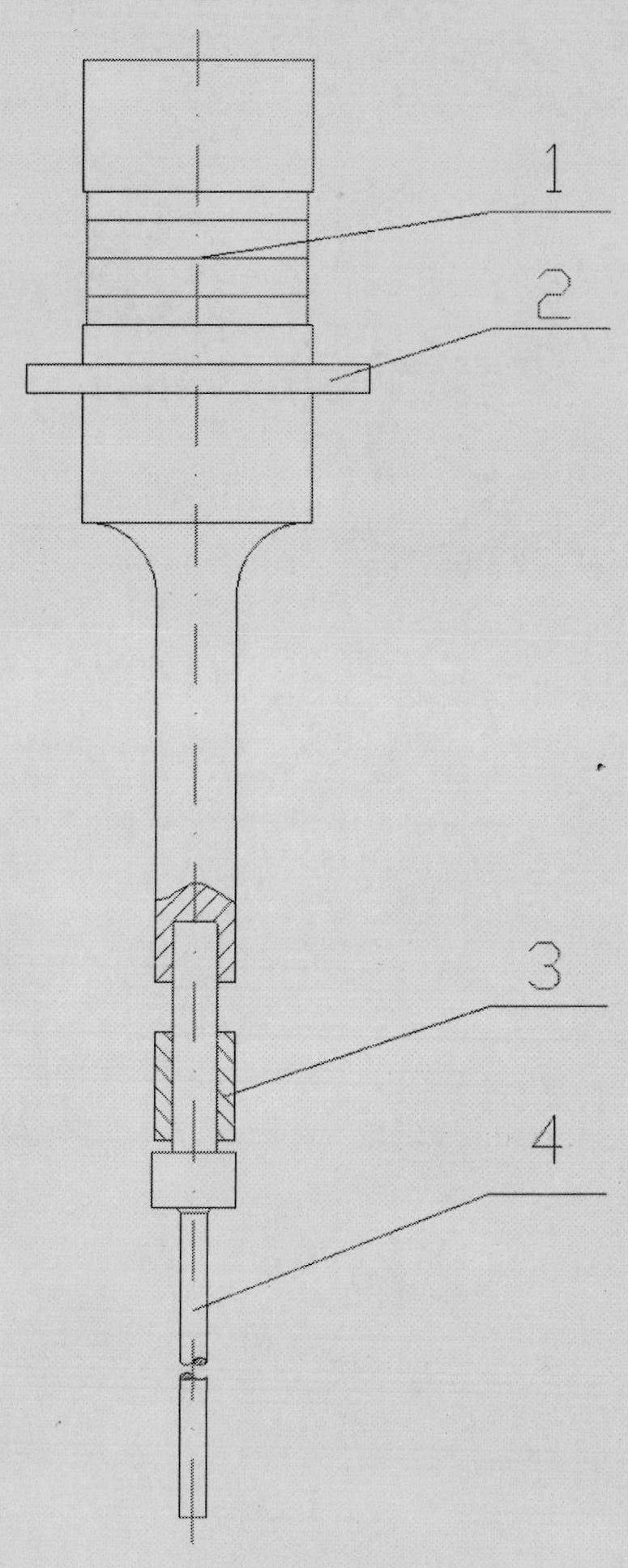

[0009] The ultrasonic excitation impact space sampling drill consists of four parts: an ultrasonic transducer (1), a pressurized clamping surface (2), a free mass (3) and a drill pipe (4). The position of the nodal surface of the ultrasonic transducer (1) is determined first, and then the pressurized clamping surface (2) is designed according to the position of the nodal surface. The ultrasonic transducer (1) is connected to the drill pipe (4) in a plug-in type, the free mass (3) is set on the drill pipe (4), and the pressurized clamping surface (2) is clamped on the test bench or manipulator. When the high-frequency AC excitation voltage is applied to the ultrasonic transducer (1), due to the inverse piezoelectric effect of piezoelectric ceramics, the ultrasonic transducer (1) produces longitudinal resonance, and the amplitude of the front end of the ultrasonic transducer (1) The rod amplifies the ultrasonic amplitude; the free mass (3) generates a high-frequency reciprocatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com