Multilayer numerical control programming method for flexible hole formation on large-scale wing part

A numerical control programming, multi-level technology, applied in the field of offline programming system, can solve the problems of poor quality, high labor intensity and time-consuming manual hole making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

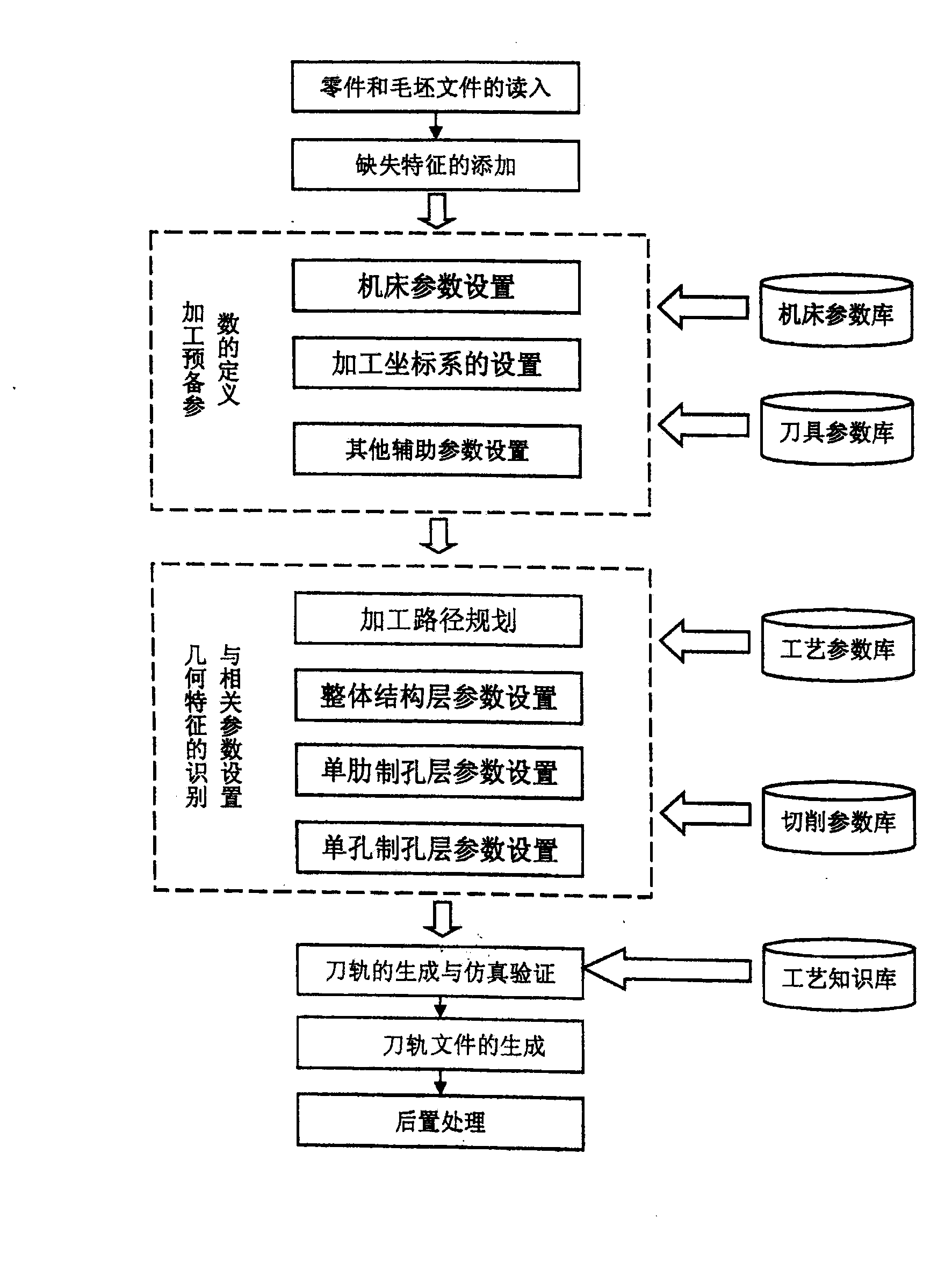

[0015] A multi-level numerical control programming method for flexible hole-making of large-scale wing parts, characterized in that it includes the following steps:

[0016] 1) Reading in parts and blank files: Add the digital model of the aircraft wing parts and its blank model for programming operations through commercial CAD software;

[0017] 2) Addition of missing features: The imported wing part model usually does not include the hole position features of the holes that need to be identified for programming. It is necessary to adopt secondary development methods for CAD software. In the digital model, the required hole position information;

[0018] 3) Extract relevant information from the machine tool parameter library and tool parameter library, and define the processing preparation parameters: the definition of the processing preparation parameters includes: machine tool parameter settings, processing coordinate system settings and other auxiliary parameter settings, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com