Composite silver wire

A silver wire and content technology, applied in metal/alloy conductors, electrical components, circuits, etc., can solve the problems of high cost of gold wires, workability (poor productivity, low yield, etc.), and achieve the effect of saving process costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

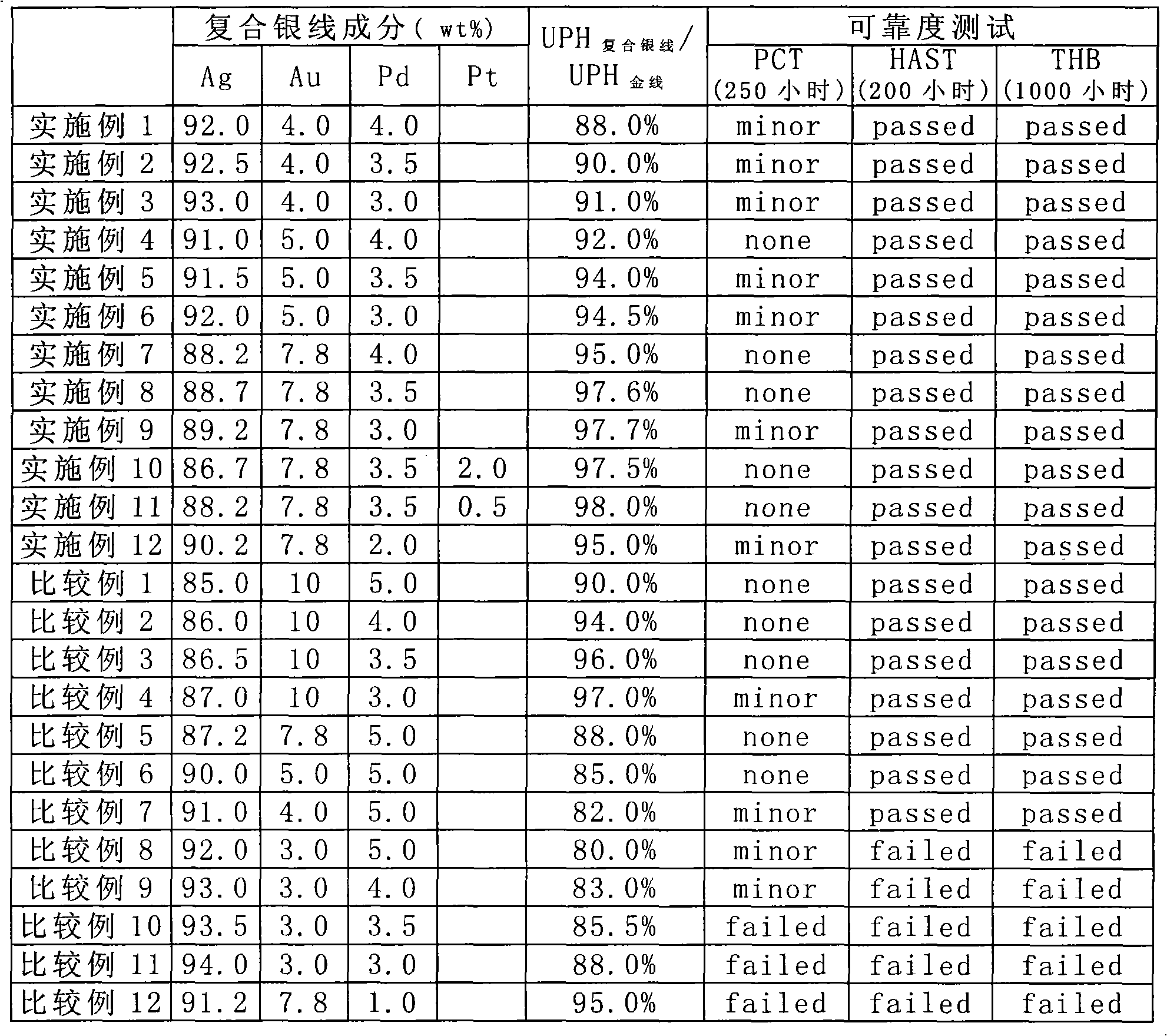

[0009] The composite silver wire of the present invention contains gold, palladium, platinum, and other components such as silver.

[0010] Wherein, the weight percentage of gold is greater than or equal to 4wt% and less than 8wt%. If the gold content is lower than 4wt%, the hardness of the alloy of the present invention will be too high, which will easily lead to poor workability. If the gold content exceeds 8wt%, The workability and reliability of the composite silver wire of the present invention not only fail to be significantly improved, but also greatly increase the cost.

[0011] The weight percentage of palladium is between 2wt% and 4wt%. If the palladium content is lower than 2wt%, the composite silver wire of the present invention cannot pass the high temperature and high humidity reliability test. If the palladium content is higher than 4wt%, the composite silver wire of the present invention cannot Alloy hardness of the composite silver wire is too high, resulting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com