Cold-hot dual-purpose pad and manufacturing method thereof

A dual-use technology for heating and cooling, and a manufacturing method that can be used in mattresses, appliances, household appliances, etc., and can solve problems such as high energy consumption, hidden safety hazards, and short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

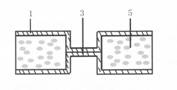

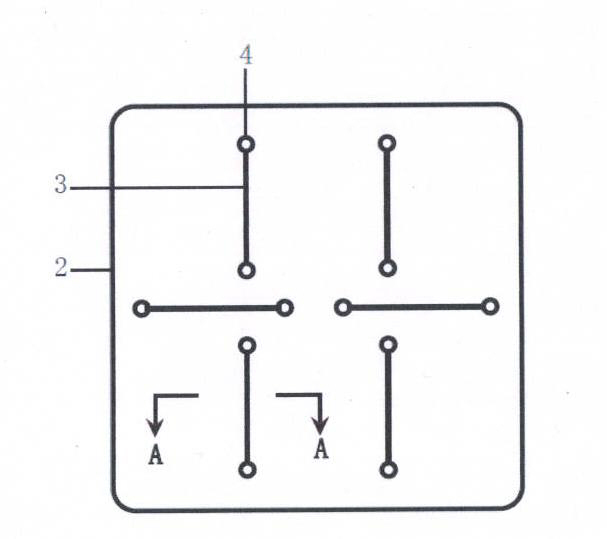

[0013] Manufacturing process: two layers of heat-sealed calendered film 1 are stacked together, and then three sides of them are welded by high frequency with a strip-shaped aluminum mold to form an outer bag 2, and the middle part of the outer bag 2 can also be welded by high frequency Several sealing strips 3 that are parallel or perpendicular to each other can be drilled. Two small holes 4 can also be drilled on both sides of the sealing strip 3 to facilitate ventilation and heat dissipation. Then fill the prepared sol 5 into a bag to remove the air in the bag and seal it. , flatten the sol 5 in the bag, and wait until the sol 5 is completely cured and shaped.

[0014] Sol configuration steps:

[0015] A: Add 4Kg of sodium polyacrylate and 400g of aluminum hydroxide into a container containing 20Kg of glycerin, and stir evenly.

[0016] B: 200g of tartaric acid, 80g of polysorbate 80, 100g of methyl chloroisothiazolinone and methyl isothiazolinone mixed in a ratio of 3: 1 ...

Embodiment 2

[0019] The manufacturing process is the same as in Example 1.

[0020] Sol configuration steps:

[0021] A: Weigh 5Kg of polyacrylamide and 480g of aluminum glycinate into a container containing 25Kg of propylene glycol, and stir evenly.

[0022] B: 240g tartaric acid, 100g polysorbate 80, 120g mixed in a 4: 1 ratio are added to a container with 70Kg of pure water respectively, Stir well.

[0023] C: Slowly add B to A, stir constantly, mix well and set aside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com