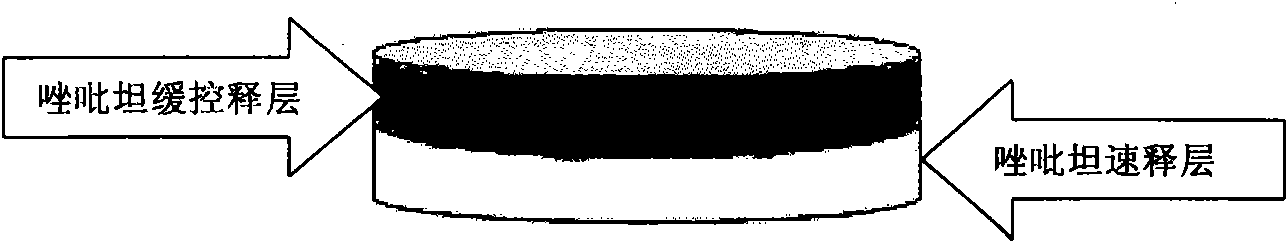

Zolpidem tartrate controlled-release double-layer tablet and preparation process of zolpidem tartrate controlled-release double-layer tablet

A zolpidem tartrate, double-layer tablet technology, applied to medical preparations containing active ingredients, pill delivery, organic active ingredients, etc., can solve the problem of slow onset of action and achieve the effect of improving bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

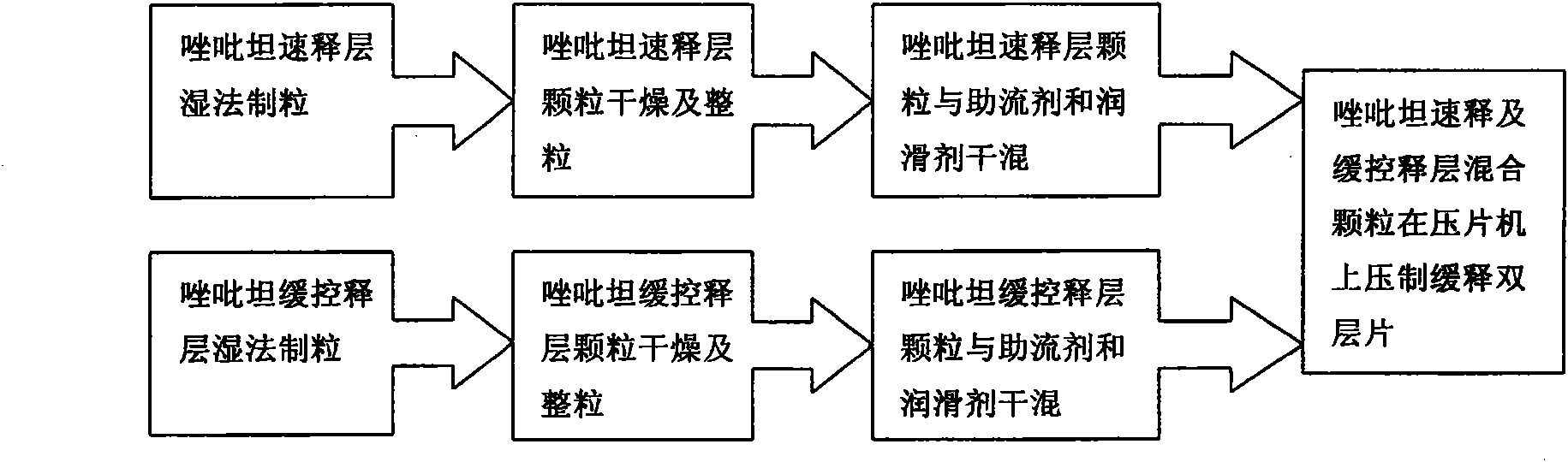

[0033] Firstly, Zolpidem Tartrate, lactose and microcrystalline cellulose (filler), croscarmellose sodium (disintegrant) and povidone (binder) were quickly released according to Table 1. The indicated amounts were accurately weighed and carefully added to the pot of the high-shear wet granulator. Before adding purified water, premix for 5 minutes at a set main knife speed of 150 rpm and a side knife speed of 1500 rpm. Then, increase the speed of the main knife to 250rpm and the speed of the side knife to 1800rpm, and add 400g of pre-weighed purified water through an atomizing nozzle at a speed of 25g / min into the same pot for wet granulation. . After the purified water is added, keep the main knife and side knife running, and continue to mix for 2 minutes. Stop granulation and transfer the Zolpidem Tartrate quick-release soft material to the fluidized bed dryer, and then use the fluidized bed to dry the soft material at 60°C until the water content of the granules is not high...

Embodiment 2

[0037] Firstly, Zolpidem Tartrate, lactose and microcrystalline cellulose (filler), croscarmellose sodium (disintegrant) and povidone (binder) are quickly released according to Table 2. The indicated amounts were accurately weighed and carefully added to the pot of the high-shear wet granulator. Before adding purified water, premix for 5 minutes at a set main knife speed of 150 rpm and a side knife speed of 1500 rpm. Then, increase the speed of the main knife to 250rpm and the speed of the side knife to 1800rpm, and add 400g of pre-weighed purified water through an atomizing nozzle at a speed of 25g / min into the same pot for wet granulation. . After the purified water is added, keep the main knife and side knife running, and continue to mix for 2 minutes. Stop granulation and transfer the Zolpidem Tartrate quick-release soft material to the fluidized bed dryer, and then use the fluidized bed to dry the soft material at 60°C until the water content of the granules is not highe...

Embodiment 3

[0041] Firstly, Zolpidem Tartrate, lactose and microcrystalline cellulose (filler), croscarmellose sodium (disintegrant) and povidone (binder) are quickly released according to Table 3. The indicated amounts were accurately weighed and carefully added to the pot of the high-shear wet granulator. Before adding purified water, premix for 5 minutes at a set main knife speed of 150 rpm and a side knife speed of 1500 rpm. Then, increase the speed of the main knife to 250rpm and the speed of the side knife to 1800rpm, and add 400g of pre-weighed purified water through an atomizing nozzle at a speed of 25g / min into the same pot for wet granulation. . After the purified water is added, keep the main knife and side knife running, and continue to mix for 2 minutes. Stop granulation and transfer the Zolpidem Tartrate quick-release soft material to the fluidized bed dryer, and then use the fluidized bed to dry the soft material at 60°C until the water content of the granules is not highe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com