Tail gas treatment device for chemical vapor deposition furnace

A chemical vapor deposition and exhaust gas treatment technology, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of abnormal wear of vacuum pump, loss of sealing function, insufficient pumping force of vacuum pump, etc., to overcome the problem of insufficient operation. , the effect of prolonging the service life and improving the control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment is a tail gas treatment device for a chemical vapor deposition furnace. The chemical vapor deposition furnace is ZGC-100 type, using nitrogen and propylene as raw material gas for chemical vapor deposition, the deposition temperature is 900±50°C, the gas flow rate is 40L / min for nitrogen, 50L / min for propylene, and the furnace pressure is 3000- 5000 Pa.

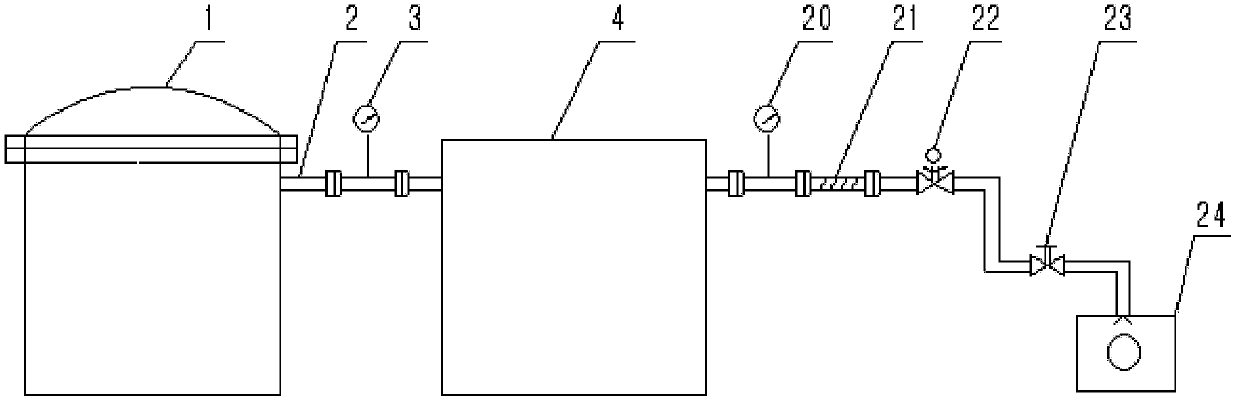

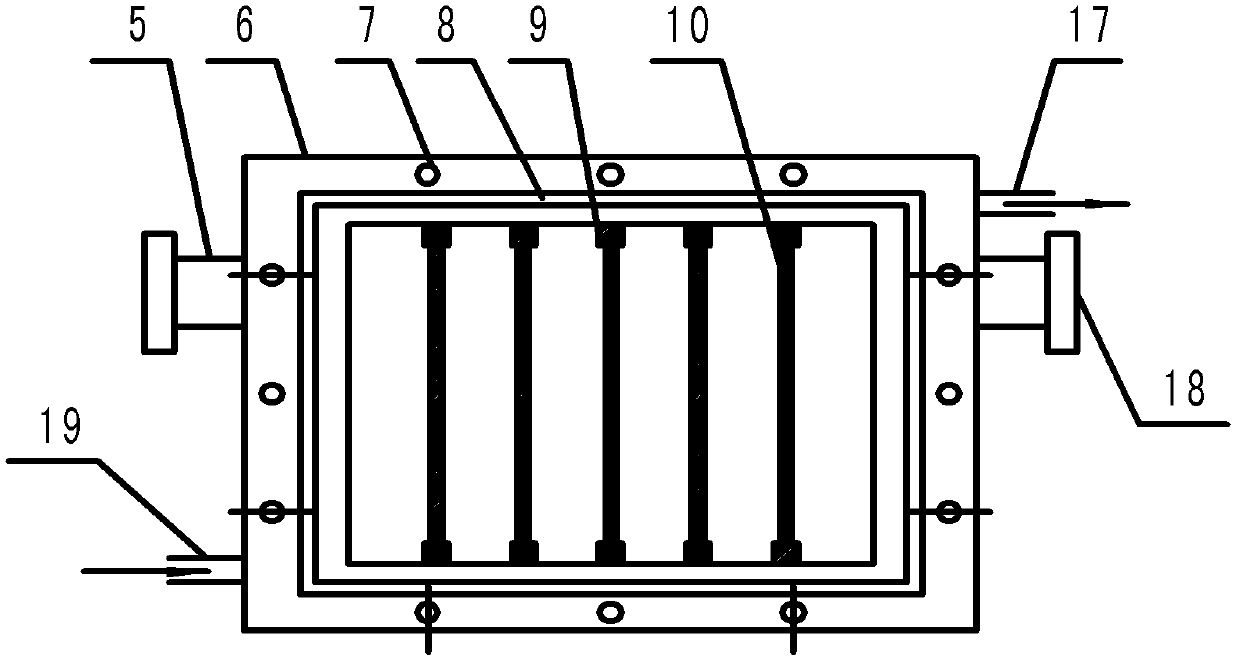

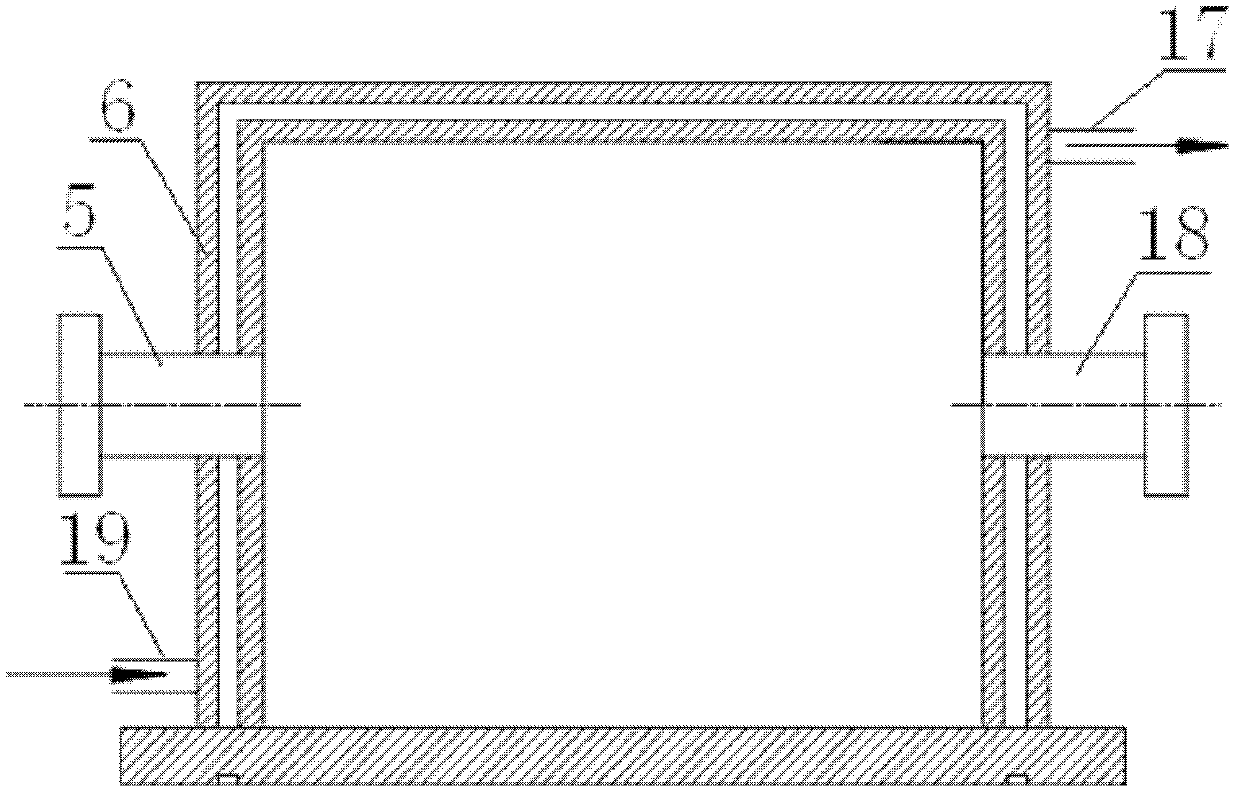

[0027] This embodiment includes a tar filter 4 , a bellows 21 and a vacuum pump 24 . The inlet of the tar filter 4 communicates with the exhaust port of the furnace body 1 through the exhaust pipe 2; the outlet of the tar filter 4 communicates with the inlet end of the bellows 21 through the pipeline. There is an inlet pressure gauge 3 between the tar filter 4 and the furnace body 1 ; and an outlet pressure gauge 20 between the outlet of the tar filter 4 and the bellows 21 . The outlet end of the bellows 21 communicates with the air inlet of the vacuum pump 24 through a pipeline; a servo valve 22 and ...

Embodiment 2

[0036] This embodiment is a tail gas treatment device for a chemical vapor deposition furnace. The chemical vapor deposition furnace is ZGCJ-500-12 type, using nitrogen and propylene as raw material gas for chemical vapor deposition, the deposition temperature is 900±50°C, the gas flow rate is 80L / min for nitrogen, 60L / min for propylene, and the furnace pressure is 3000-5000Pa.

[0037] This embodiment includes a tar filter 4 , a bellows 21 and a vacuum pump 24 . The inlet of the tar filter 4 communicates with the exhaust port of the furnace body 1 through the exhaust pipe 2; the outlet of the tar filter 4 communicates with the inlet end of the bellows 21 through the pipeline. There is an inlet pressure gauge 3 between the tar filter 4 and the furnace body 1 ; and an outlet pressure gauge 20 between the outlet of the tar filter 4 and the bellows 21 . The outlet end of the bellows 21 communicates with the air inlet of the vacuum pump 24 through a pipeline; a servo valve 22 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com