Hydrotreatment catalyst and preparation method thereof

A hydrotreating and catalyst technology, applied in physical/chemical process catalysts, catalyst carriers, chemical instruments and methods, etc., can solve the problems of uneven dispersion, poor alumina modification effect, etc., and achieve the improvement of hydrodesulfurization activity, The effect of improving surface acidity and pore structure and improving hydrodenitrogenation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Take 30 grams of aluminum hydroxide dry glue containing 4w% of F and 2w% of silicon oxide and 70 grams of aluminum hydroxide dry glue of 10w% containing zirconia and mix them evenly with 5 grams of squash powder, add 90ml of Dilute nitric acid solution with a concentration of 3%, mixed evenly, extruded into strips, dried at 120°C for 4 hours, and calcined at 550°C for 4 hours to prepare modified carrier SA-1.

[0020] Take 30 grams of aluminum hydroxide dry glue containing 6w% F and 2w% silicon oxide and 70 grams of aluminum hydroxide dry glue containing 10w% zirconia and mix them evenly with 5 grams of squash powder, and follow the above steps Preparation of modified carrier SA-2.

[0021] Take 30 grams of aluminum hydroxide dry glue containing 10w% of F and 2w% of silicon oxide and 70 grams of aluminum hydroxide dry glue of 10w% containing zirconia and mix them evenly with 5 grams of squash powder, and follow the above steps Preparation of modified carrier SA-3.

[...

Embodiment 2

[0025] 51.5 grams of molybdenum trioxide, 13.2 grams of basic nickel carbonate, 10.3 grams of 85% phosphoric acid were dissolved and calibrated to 100ml to obtain a Ni-Mo-P impregnation solution, and 100 grams of SA-1 carrier was impregnated with 75ml of the impregnation solution in equal volumes at 120 It was dried at ℃ for 4 hours and calcined at 400℃ for 4 hours to prepare catalyst A-1.

[0026] The SA-2, SA-3, SA-4 and SA-5 carriers were respectively impregnated with the same impregnating solution to prepare A-2, A-3, A-4 and A-5 catalysts respectively.

Embodiment 3

[0037] This example is an activity evaluation test of the catalyst of the present invention and compared with other catalysts. The evaluation is carried out on a 100ml small-scale hydrogenation device, and the evaluation conditions are: reaction pressure 10.0MPa, hydrogen-oil volume ratio 500:1, volume space velocity 1.5h -1 , The reaction temperature is 380°C. The properties of the raw oil used are shown in Table 1, and the evaluation results are shown in Table 2.

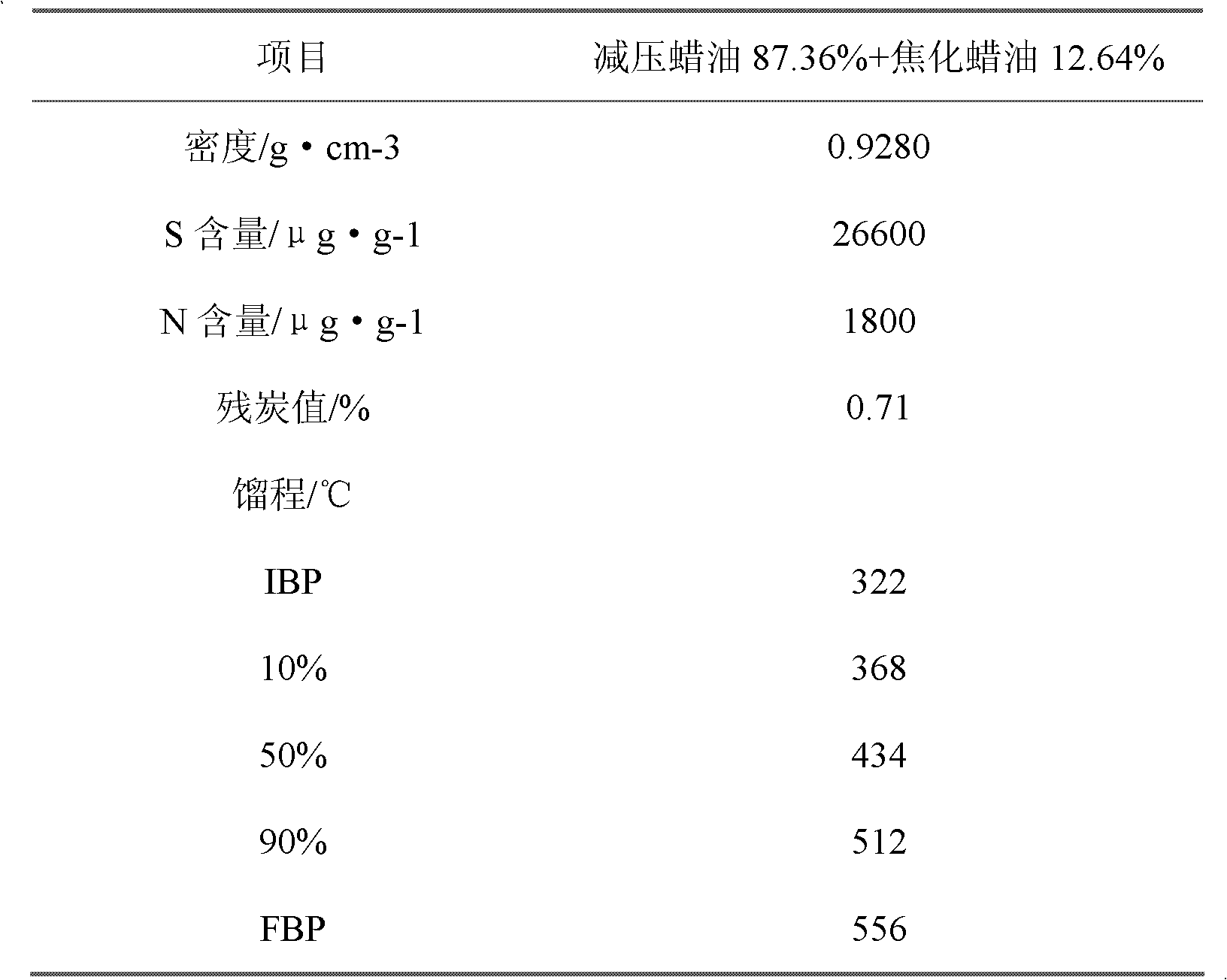

[0038] Table 1 Evaluation of raw oil properties

[0039]

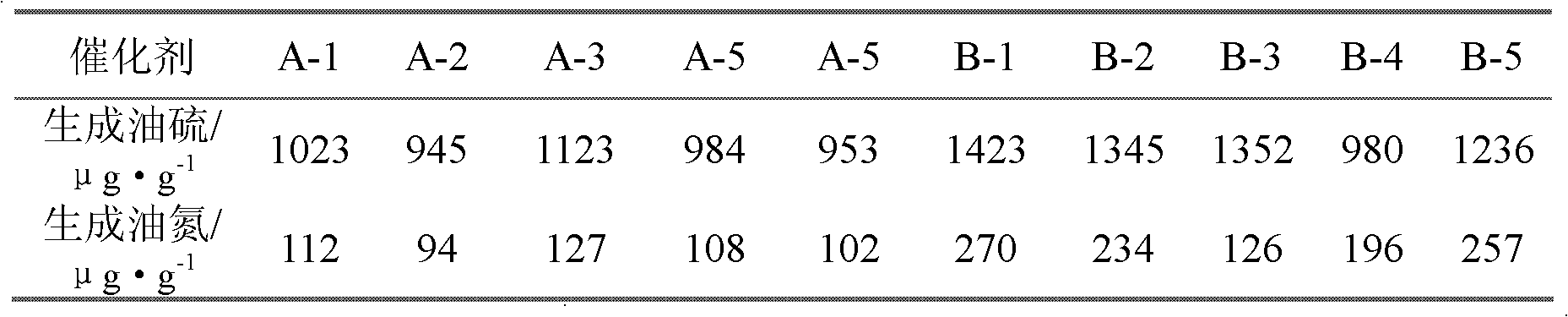

[0040] Table 2 Catalyst evaluation results

[0041]

[0042] As can be seen from Table 2, under the same process conditions, the catalyst of the present invention has a better pore structure and surface acidity, and the modified carrier and catalyst are prepared by using F, Si, Zr combined modified aluminum hydroxide dry glue to improve the carrier And the surface acidity of the catalyst, while improving the hydrodesulfurization activity of the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com