Method for screening catalyst for Fischer Tropsch synthesis

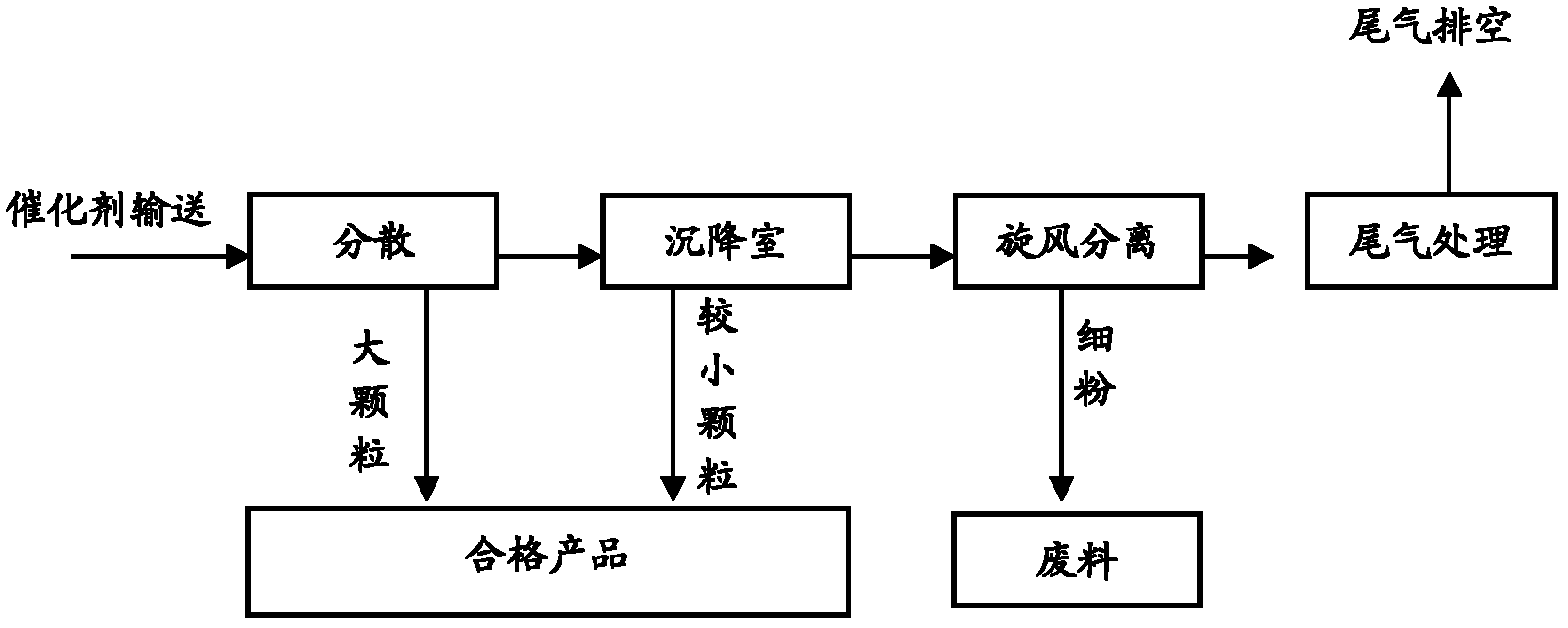

A Fischer-Tropsch synthesis and catalyst technology, applied in chemical instruments and methods, separating solids from solids with airflow, solid separation, etc., can solve the problems of catalyst crushing, dust pollution, high labor intensity, etc., and achieve reduction Catalyst loss, reduced environmental pollution, and simple screening operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

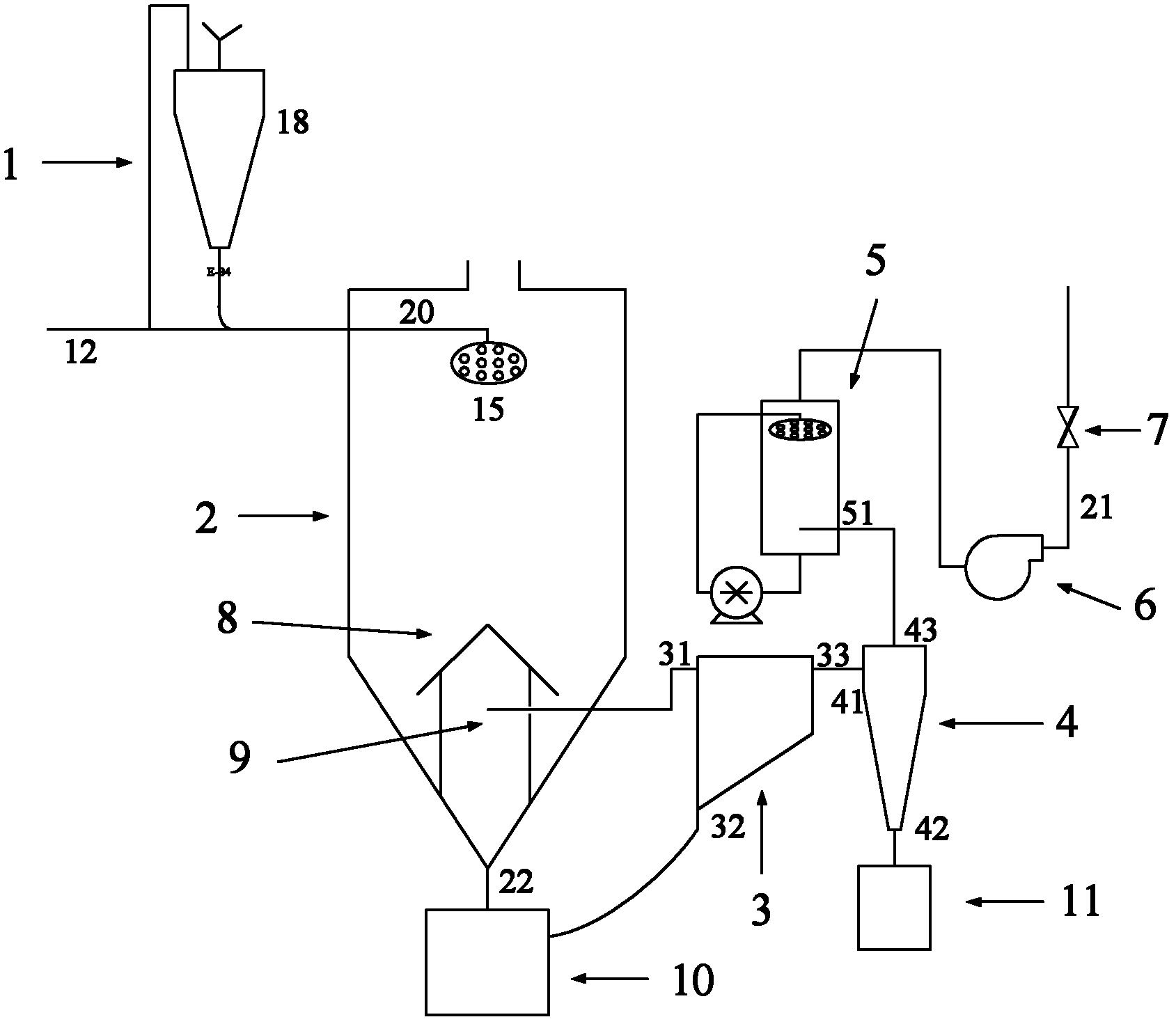

Method used

Image

Examples

Embodiment 1

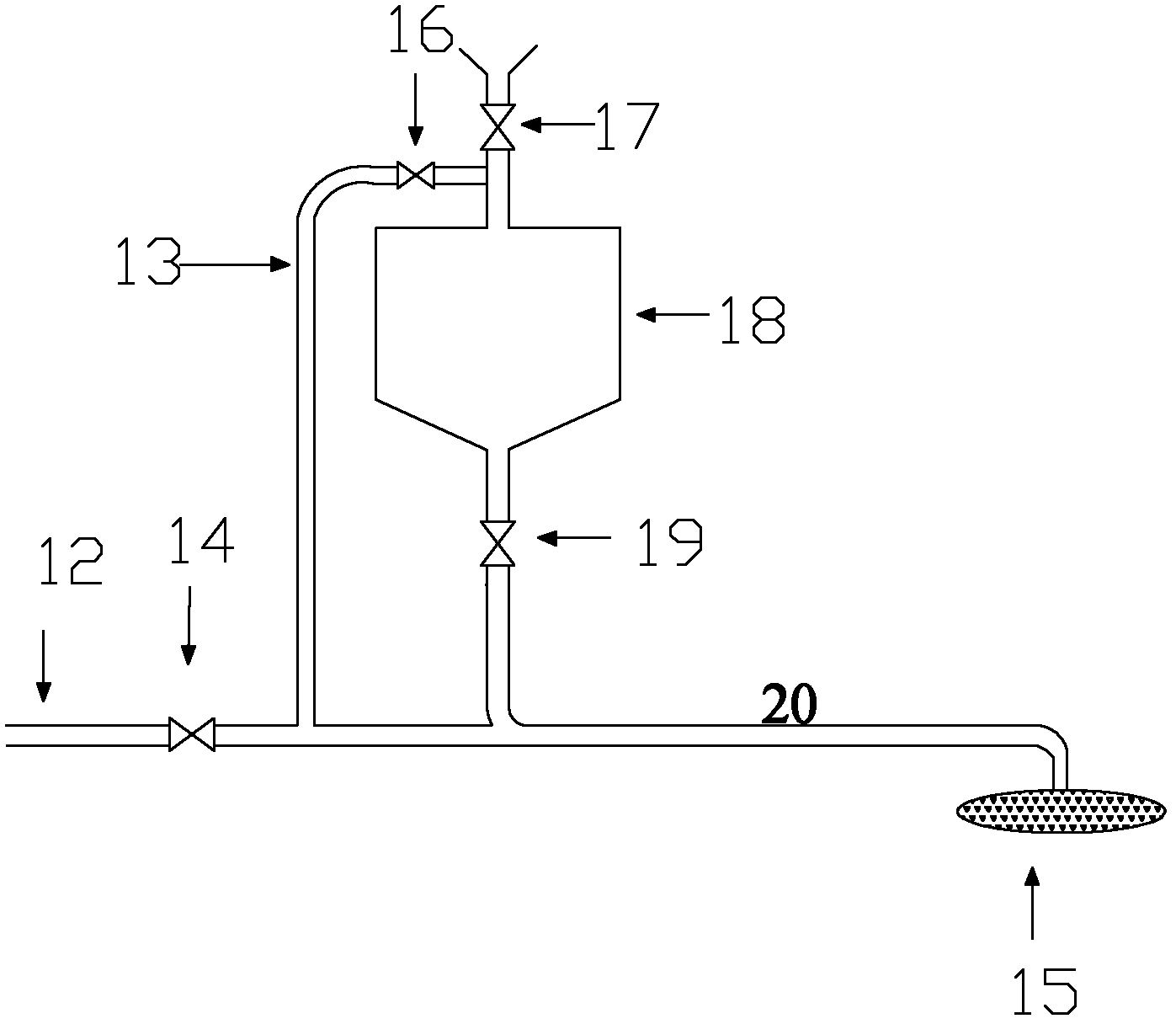

[0080] Weigh 5kg from the uniformly mixed Fischer-Tropsch synthesis iron-based catalyst to be screened in the above comparative example 1, coded as C, put it into the catalyst charging barrel, control the compressed gas inlet pressure to 0.5bar, and fully open the air induction Butterfly valve 7, fully open discharge valve 19, the catalyst enters the dispersion tower with the compressed gas and disperses. After the catalyst is sieved, the finished catalyst is collected and weighed, and 50g of the finished catalyst is evenly taken for laser particle size analyzer testing. The obtained results Listed in Table 1.

Embodiment 2

[0082] Weigh 5kg from the Fischer-Tropsch synthesis iron-based catalyst to be screened uniformly mixed in the above comparative example 1, coded as D, put it into the catalyst charging barrel, control the compressed gas inlet pressure to 1.0bar, and fully open the induced wind butterfly valve 7. Fully open the discharge valve 19, and the catalyst enters the dispersion tower with the compressed gas to disperse. After the catalyst is sieved, collect the finished catalyst and weigh it, and evenly take 50g of the finished catalyst for the laser particle size analyzer test. The obtained results are listed in Table 1.

Embodiment 3

[0084] Weigh 5kg from the evenly mixed Fischer-Tropsch synthesis iron-based catalyst to be screened in Comparative Example 1, coded as E, put it into the catalyst charging barrel, control the compressed gas inlet pressure to 0.5bar, and fully open the air induction Butterfly valve 7, half-open discharge valve 19, the catalyst enters the dispersion tower with the compressed gas and disperses, after the catalyst screening is completed, collect the finished catalyst and weigh it, evenly take 50g of the finished catalyst, use a laser particle size analyzer to test, and obtain The results are listed in Table 1.

[0085] Table 1 Catalyst laser particle size analysis results

[0086]

[0087] It can be seen from the data in Table 1 that before the catalyst was screened, the content of the catalyst less than 50 μm accounted for 14.6% of the total amount of the catalyst, and it was reduced to 2.2% after three times of mechanical vibrating screening with a standard sieve. The conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com