On-line quality measurement device for plastic product on extruder

A product quality and measuring device technology, applied in the field of on-line measuring devices for plastic product quality on extruders, can solve problems such as limited information, lagging real-time production control, economic losses, etc., achieve accurate control parameters, ensure processing quality, reduce The effect of scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

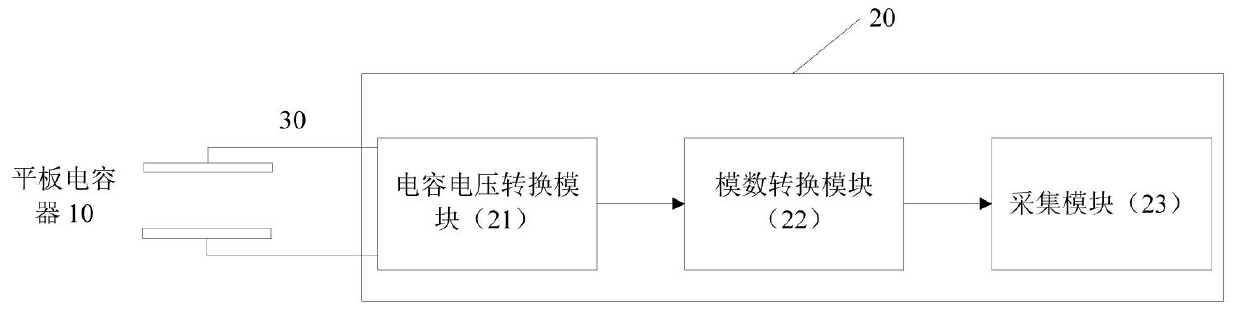

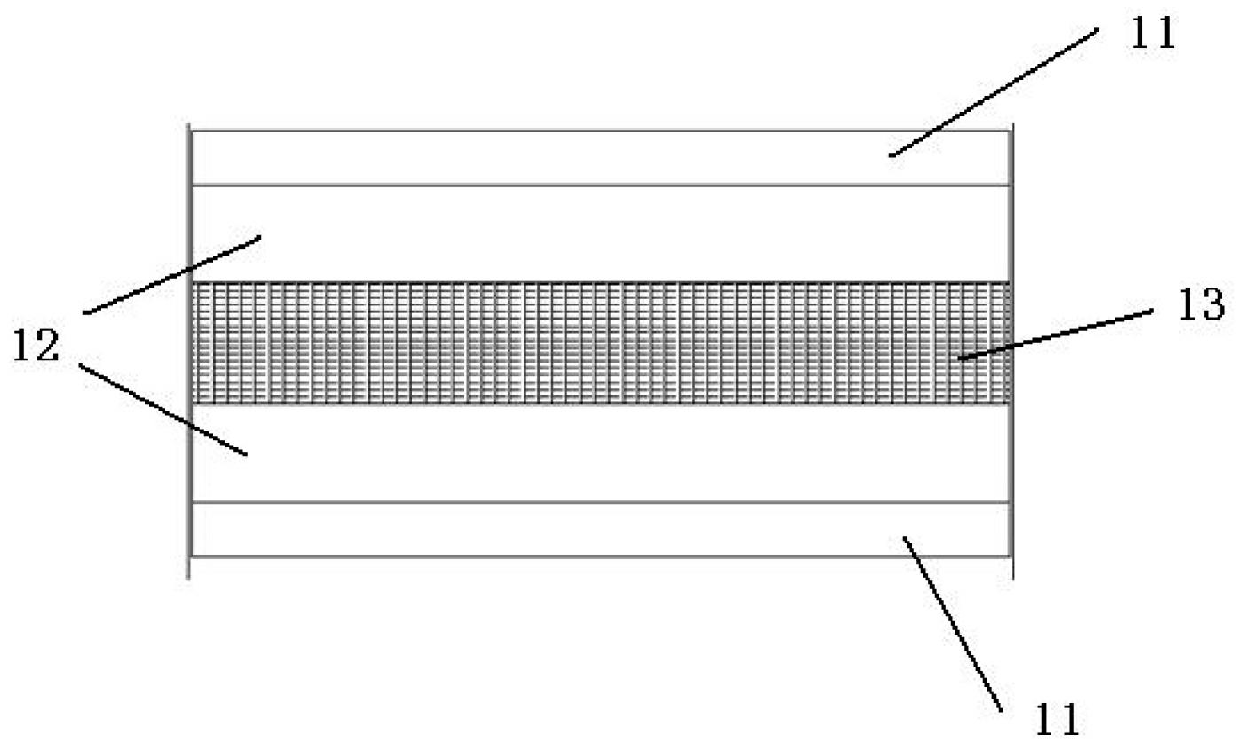

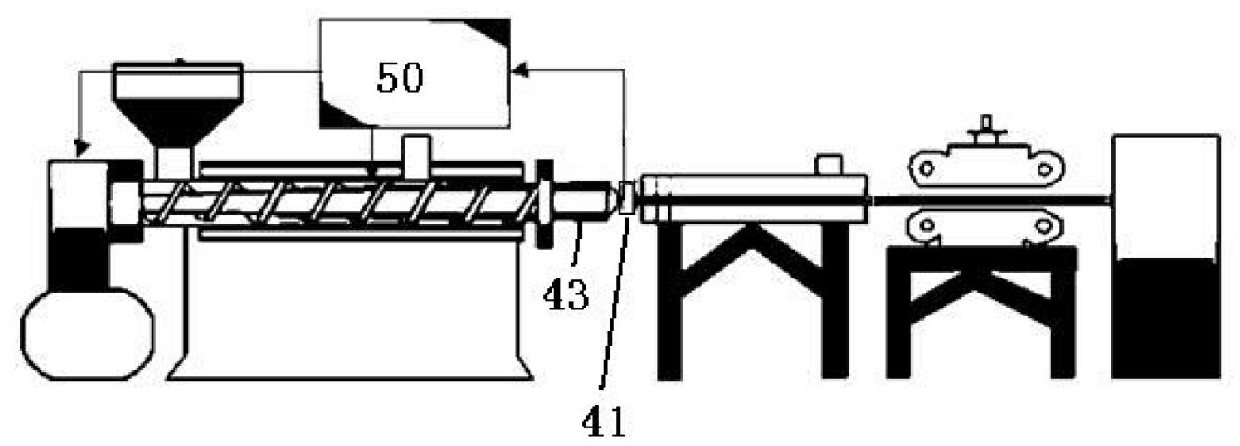

[0025] In embodiment one, the number of plate capacitors 10 is one, refer to image 3 , the two electrodes 11 of the flat plate capacitor 10 are radially fixed on both symmetrical sides of the exit 41 of the extrusion head on the extruder through an insulating material.

[0026] When the extrusion process did not take place, the dielectric layer between the two electrodes 11 of the flat capacitor 10 was air 11, and the capacitance value of the flat capacitor 10 was C 0 , , where ε 0 is the dielectric constant of the medium between the electrodes, S is the relative area of the two electrodes, and D is the relative distance between the two electrodes. Changing any one of these 3 parameters will change the capacitance value of the plate capacitor.

[0027] When the extrusion process takes place, once the extruded material passes through the flat capacitor 10 after coming out of the extrusion head 43, since the dielectric layer between the two electrodes 11 of the flat capac...

Embodiment 2

[0033] In embodiment two, the number of plate capacitors 10 is two, refer to Figure 4 , the two electrodes of one of the flat capacitors are radially fixed on the symmetrical sides of the extrusion head exit 41 on the extruder through insulating materials, and the two electrodes of the other flat capacitor are fixed radially on the extruder through insulating materials Symmetrical both sides of the outlet 42 of the cooling water tank.

[0034] Similarly, during the extrusion process, the formula for calculating the capacitance values of the two flat capacitors in this embodiment is applicable to formula 1, namely .

[0035] When the extrusion material comes out of the extrusion head 43 and passes through the plate capacitor 10 at the exit 41 of the extrusion head, the capacitance measuring unit 20 can measure whether the heating and extrusion process of the extruded product in the barrel is uniform;

[0036] When the extruded material passes through the cooling water tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com