Separable self-drilling embedment anchor

A separate, self-drilling technology, which is applied to anchor points, ship parts, transportation and packaging, etc., can solve the problems of the reduced effect of embedded anchors of rockets, the inability of anchor bodies to provide anchoring force, and high requirements for rocket thrust, and achieve low cost, Enhance the anchoring force of the anchor body and increase the effect of embedding depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Embodiment 1: A separate self-drilling embedded anchor and its working process.

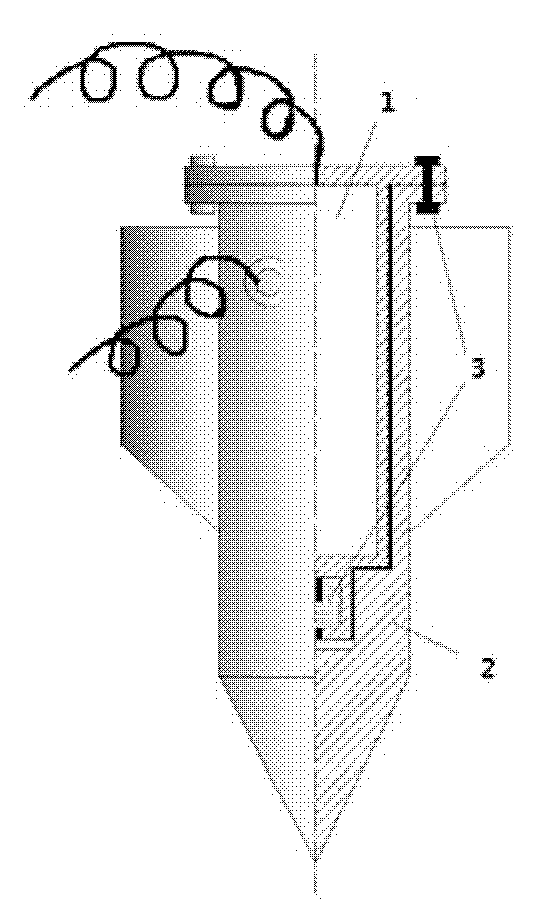

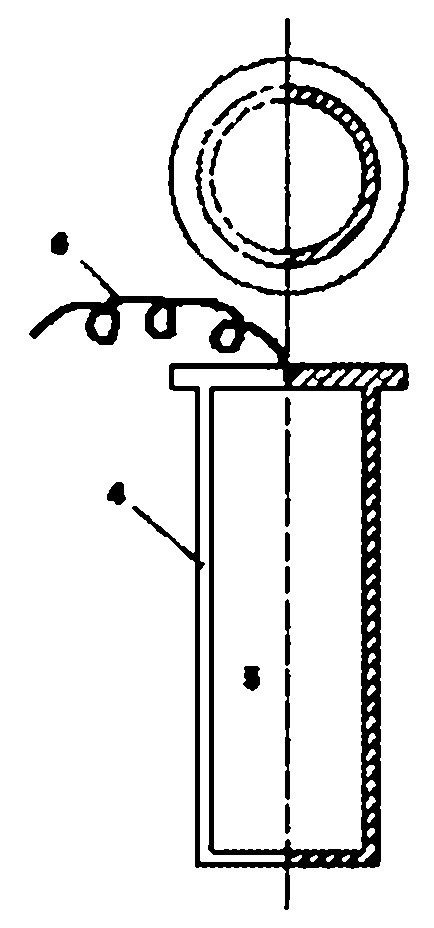

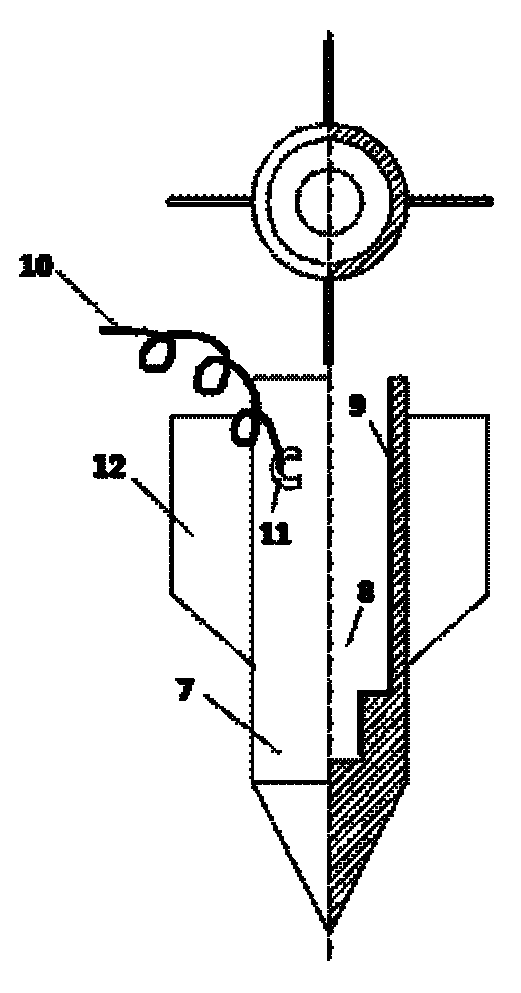

[0061] Such as figure 1 As shown, the dynamic anchor consists of three parts: a propeller 1 , an anchor body 2 and a separating member 3 . Such as figure 2 As shown, the propeller 1 includes: a propeller casing 4, an electromagnetic vibrator 5, and a cable 6; as image 3 As shown, the anchor body 2 includes: the anchor body shell 7, the inner cavity 8, the cavity wall lubricating layer 9, the anchor chain 10, the anchor ring 11, and the main fin 12; the separation member 3 includes a flange 13, an explosion bolt 14, and a combustion chamber 15 , fuel 16, electric lighter 17, injection hole 18 and sealing plug 19.

[0062] The working water depth of this embodiment is 30m. Propeller 1 weighs 150kg, and its shell 4 is a hollow cylinder made of high-strength titanium alloy steel, with a diameter of 178mm and a length of 1.5m; the electromagnetic vibrator 5 is a device that generates vibr...

Embodiment 2

[0071] Embodiment 2: A separate self-drilling embedded anchor and its working process.

[0072] Such as figure 1 As shown, the dynamic anchor consists of three parts: a propeller 1 , an anchor body 2 and a separating member 3 . Such as figure 2 As shown, the propeller 1 includes: a propeller casing 4, a pneumatic turbine vibrator 5, a cable 6; as image 3 As shown, the anchor body 2 includes: the anchor body shell 7, the inner cavity 8, the cavity wall lubricating layer 9, the anchor chain 10, the anchor ring 11, and the main fin 12; the separation member 3 includes a flange 13, an explosion bolt 14, and a combustion chamber 15 , fuel 16, electric lighter 17, injection hole 18 and sealing plug 19.

[0073] The working water depth of this embodiment is 20m. Propeller 1 weighs 160kg, and its shell 4 is a hollow cylinder made of high-strength titanium alloy steel, with a diameter of 188mm and a length of 1.5m; the pneumatic turbine vibrator 5 is a device that drives the ecce...

Embodiment 3

[0082] Embodiment 3: A separate self-drilling embedded anchor and its working process.

[0083] Such as figure 1 As shown, the dynamic anchor consists of three parts: a propeller 1 , an anchor body 2 and a separating member 3 . Such as figure 2 As shown, the propeller 1 includes: a propeller casing 4, an air hammer 5, and a cable 6; as image 3 As shown, the anchor body 2 includes: the anchor body shell 7, the inner cavity 8, the cavity wall lubricating layer 9, the anchor chain 10, the anchor ring 11, and the main fin 12; the separation member 3 includes a flange 13, an explosion bolt 14, and a combustion chamber 15 , fuel 16, electric lighter 17, injection hole 18 and sealing plug 19.

[0084]The working water depth of this embodiment is 20m. Propeller 1 weighs 160kg, and its shell 4 is a hollow cylinder made of high-strength titanium alloy steel material, with a diameter of 188mm and a length of 1.5m; the air hammer 5 is a device that drives the piston to reciprocate w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com