Gas hydrate generation promoter and preparation method thereof

A gas hydrate and accelerator technology, which is applied in the preparation of sulfonate, organic chemistry, etc., can solve the problems of unsatisfactory promotion effect of additives, shortening induction time, etc., to speed up hydrate formation, reduce energy consumption, and simple preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Dissolve 12.215g of 1,3-propane sultone in 100mL of toluene, slowly add 9.915g of cycloheximide dropwise under ice bath and vigorous stirring, the two compounds are 0.1mol. After dropping, react in a water bath at 70°C for 8 h, filter the light yellow precipitate formed by the reaction, wash the filter cake with ethyl acetate and ether three times in turn, and dry at 100°C to obtain a light yellow solid which is the ionic liquid Precursor 1-(3-sulfopropyl)cyclohexylimide salt (HMIPS), its mass is 21.47g;

[0029] (2) Dissolve 0.05mol or 11.066g of HMIPS in water, add 2.8mL of 18mol / L p-toluenesulfonic acid solution dropwise at room temperature, and slowly raise the temperature to 80°C for 24 hours in a water bath to obtain a light yellow transparent liquid. Titrate to neutral with NaOH, distill under reduced pressure to remove water, then wash with methanol and ether for 3 times respectively, and distill under reduced pressure again after washing to obtain the sulfo...

Embodiment 2

[0033] (1) Same as above-mentioned embodiment 1 step (1)

[0034] (2) Dissolve 0.05mol or 11.066g of HMIPS in water, add 10.0mL of 5moL / L p-toluenesulfonic acid solution dropwise at room temperature, and slowly raise the temperature to 80°C for 24 hours in a water bath to obtain a light yellow transparent liquid. Titrate to neutral with NaOH, remove water by distillation under reduced pressure, wash with methanol and ether three times respectively, and distill under reduced pressure again after washing to obtain sulfonic acid functionalized ionic liquid [HMIPS]OTs, and dry at 100 °C to obtain 18.63 g.

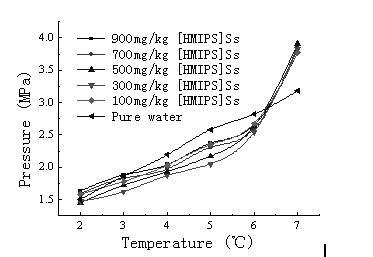

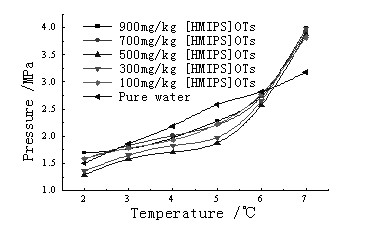

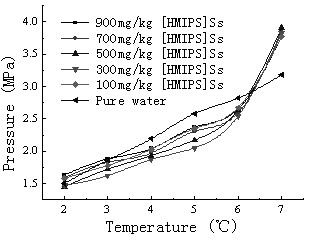

[0035] (3) The obtained [HMIPS]OTs product was dissolved and prepared into ionic liquid solutions with concentrations of 100, 300, 500, 700, and 900 mg / kg. The following hydrate synthesis experiments verified that [HMIPS]OTs at different concentrations and temperatures CO in ionic liquid solution 2 The pressure of hydrate generation is compared with the data of pure water und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com