Coating for wind power generation blades

A technology for wind power generation blades and coatings, applied in coatings and other directions, can solve problems such as adhesion, wear resistance, low temperature stability, and non-icing of the surface layer, and achieve excellent weather resistance, good hydrophobicity, and improved wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Prepared according to the following mass percentage content feeding ratio:

[0011] Polyvinyl butyral 20%;

[0012] Hydroxy acrylic resin 20%;

[0013] Ethoxy-terminated Dimethicone 35%;

[0014] Ethanol 8%;

[0015] n-Butanol 10%;

[0016] al 2 o 3 5%;

[0017] SiO 2 2%.

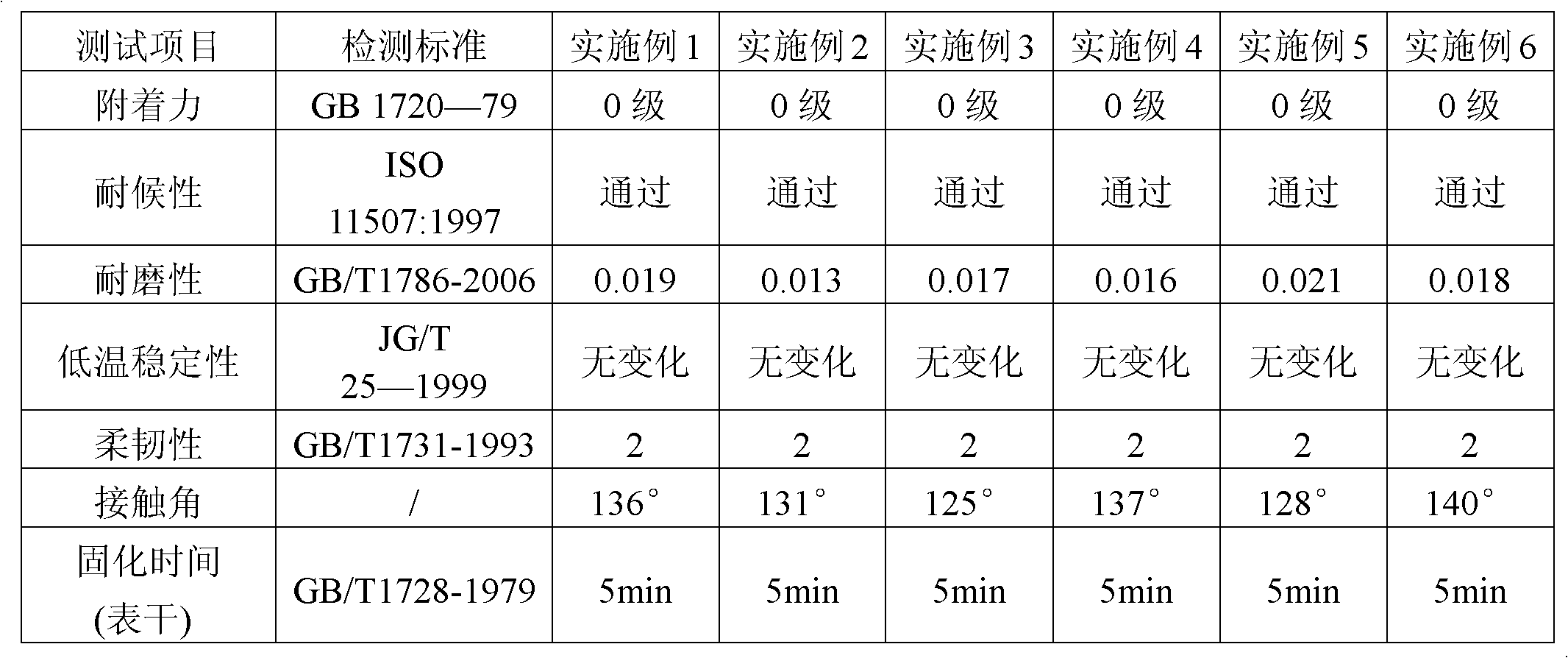

[0018] Dissolve polyvinyl butyral in a solution mixed with ethanol and n-butanol, then add ethoxy-terminated dimethylpolysiloxane and hydroxyacrylic resin to the system, stir well and react at room temperature 4 hours; Add Al to the product obtained above 2 o 3 with SiO 2 Disperse, grind and filter to obtain the coating for wind power generation blades. The above-mentioned paint was sprayed on the tinplate sheet, and the test results of various technical indicators are shown in Table 1.

Embodiment 2

[0020] Prepared according to the following mass percentage content feeding ratio:

[0021] Polyvinyl butyral 23%;

[0022] Hydroxy Acrylic Resin 18%;

[0023] Ethoxy-terminated Dimethicone 34%;

[0024] Ethanol 8.3%;

[0025] n-Butanol 9.7%;

[0026] al 2 o 3 5.2%;

[0027] SiO 2 1.8%.

[0028] Dissolve polyvinyl butyral in a solution mixed with ethanol and n-butanol, then add ethoxy-terminated dimethylpolysiloxane and hydroxyacrylic resin to the system, stir well and react at room temperature 4 hours; Add Al to the product obtained above 2 o 3 with SiO 2 Disperse, grind and filter to obtain the coating for wind power generation blades. The above-mentioned paint was sprayed on the tinplate sheet, and the test results of various technical indicators are shown in Table 1.

Embodiment 3

[0030] Prepared according to the following mass percentage content feeding ratio:

[0031] Polyvinyl butyral 25%;

[0032] Hydroxy Acrylic Resin 17%;

[0033] Ethoxy-terminated Dimethicone 33%;

[0034] Ethanol 9.6%;

[0035] n-Butanol 8.4%;

[0036] al 2 o 3 5.4%;

[0037] SiO 2 1.6%.

[0038] Dissolve polyvinyl butyral in a solution mixed with ethanol and n-butanol, then add ethoxy-terminated dimethylpolysiloxane and hydroxyacrylic resin to the system, stir well and react at room temperature 4 hours; Add Al to the product obtained above 2 o 3 with SiO 2 Disperse, grind and filter to obtain the coating for wind power generation blades. The above-mentioned paint was sprayed on the tinplate sheet, and the test results of various technical indicators are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com