Tobacco extract, and extraction method and application thereof

A technology of tobacco extract and extraction method, applied in the field of tobacco flavor, can solve the problems of breeding and spreading pests and diseases, waste of resources, polluting the atmosphere, etc., and achieve the effects of improving the quality of cigarette smoking, improving aftertaste and high extraction rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Grind the bast of the naturally dried tobacco stems into 80 meshes, add 95% (volume fraction, the same below) ethanol which is 6 times its mass, extract by reflux at 80°C for 3 hours, cool and filter, and adjust the pH with sodium hydroxide value to 7.0, add neutral protease (enzyme activity 50,000 u / g) with a mass concentration of 6.0 g / L, extract at 40°C for 4 hours, and concentrate at 80°C to obtain a crude extract. For the crude extract of the extract, use 95% ethanol which is 3 times its mass as the extractant, and the extract is obtained after distillation. The obtained extract is placed in a brown bottle and sealed and refrigerated.

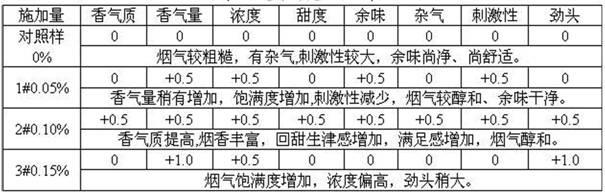

[0020] Dilute the obtained extract with water to 1% (wt%, the same below), according to the ratio of adding 50g (the addition ratio of the extract is 0.05%) of the diluent to 1000g of tobacco leaves, spray it evenly into the leaves, place it at room temperature for 2h, absorb Finally, cut into shreds, dry shreds, and make cigarette...

Embodiment 2

[0022] Grind the naturally dried tobacco stem bast into 60 meshes, add 5 times its mass of 90% ethanol, reflux extraction at 70°C for 4 hours, cool and filter, adjust the pH value to 6.5 with sodium hydroxide, and add a mass concentration of 6.0g / L of neutral protease (50,000 u / g), extracted at 50°C for 5h, concentrated at 70°C to obtain a crude extract. For the crude extract of the extract, 4 times the volume fraction of 95% ethanol is used as the extractant, and the extract is obtained after distillation. The obtained extract is placed in a brown bottle and sealed and refrigerated.

[0023] Dilute the obtained extract with water to 2%, add 50g (the addition ratio of the extract is 0.10%) of diluent to 1000g of tobacco leaves, evenly spray it into the leaves, place it at room temperature for 2h, and cut it into shreds according to the normal process after absorption. Dried silk, cigarettes.

Embodiment 3

[0025] Grind the naturally dried tobacco stem bast into 70 meshes, add 6 times the volume fraction of 85% ethanol, extract at 80°C for 4 hours, cool and filter, adjust the pH value to 7.0 with sodium hydroxide, and add a mass concentration of 6.0 g / L neutral protease (50,000 u / g), extract at 55°C for 6h, and concentrate at 60°C to obtain crude extract. For the crude extract of the extract, 3 times the volume fraction of 95% ethanol is used as the extractant, and the extract is obtained after distillation. The obtained extract is placed in a brown bottle and sealed and refrigerated.

[0026] Dilute the obtained extract to 3% with ethanol with a volume fraction of 75%, and spray it evenly into the leaves according to the ratio of adding 50g (the addition ratio of the extract is 0.15%) to 1000g of tobacco leaves, and place it at room temperature for 2 hours. Shredded, dried and rolled according to the normal process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com