Coal roadway tunneling machine with double round cutter heads

A technology of circular cutter head and roadheader, which is applied to cutting machinery, mining equipment, earthwork drilling and mining, etc. It can solve the problems of longer anchorage time, longer empty head distance, and shorter service life, so as to improve the safety operation factor and reduce dust Content, the effect of ensuring safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

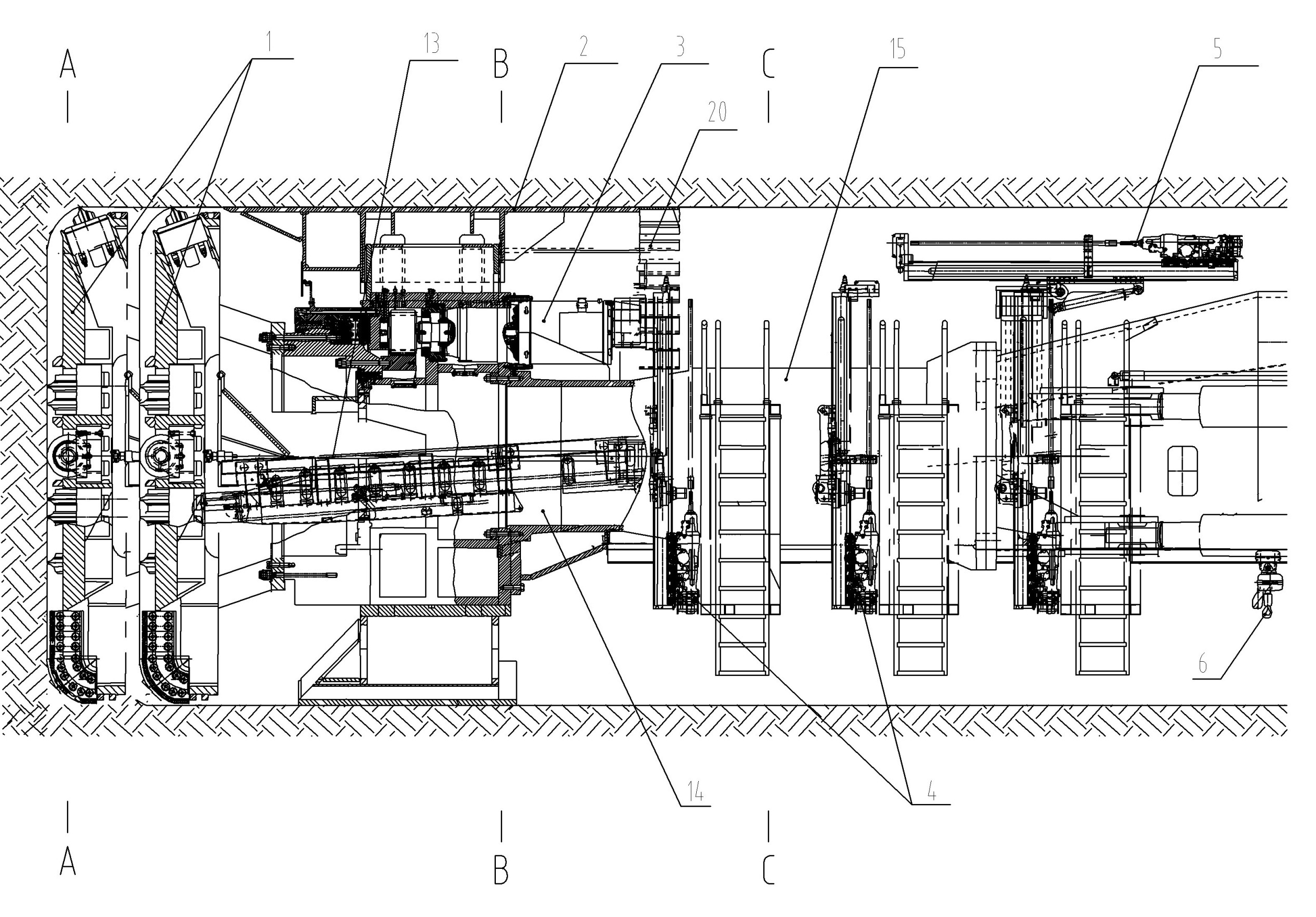

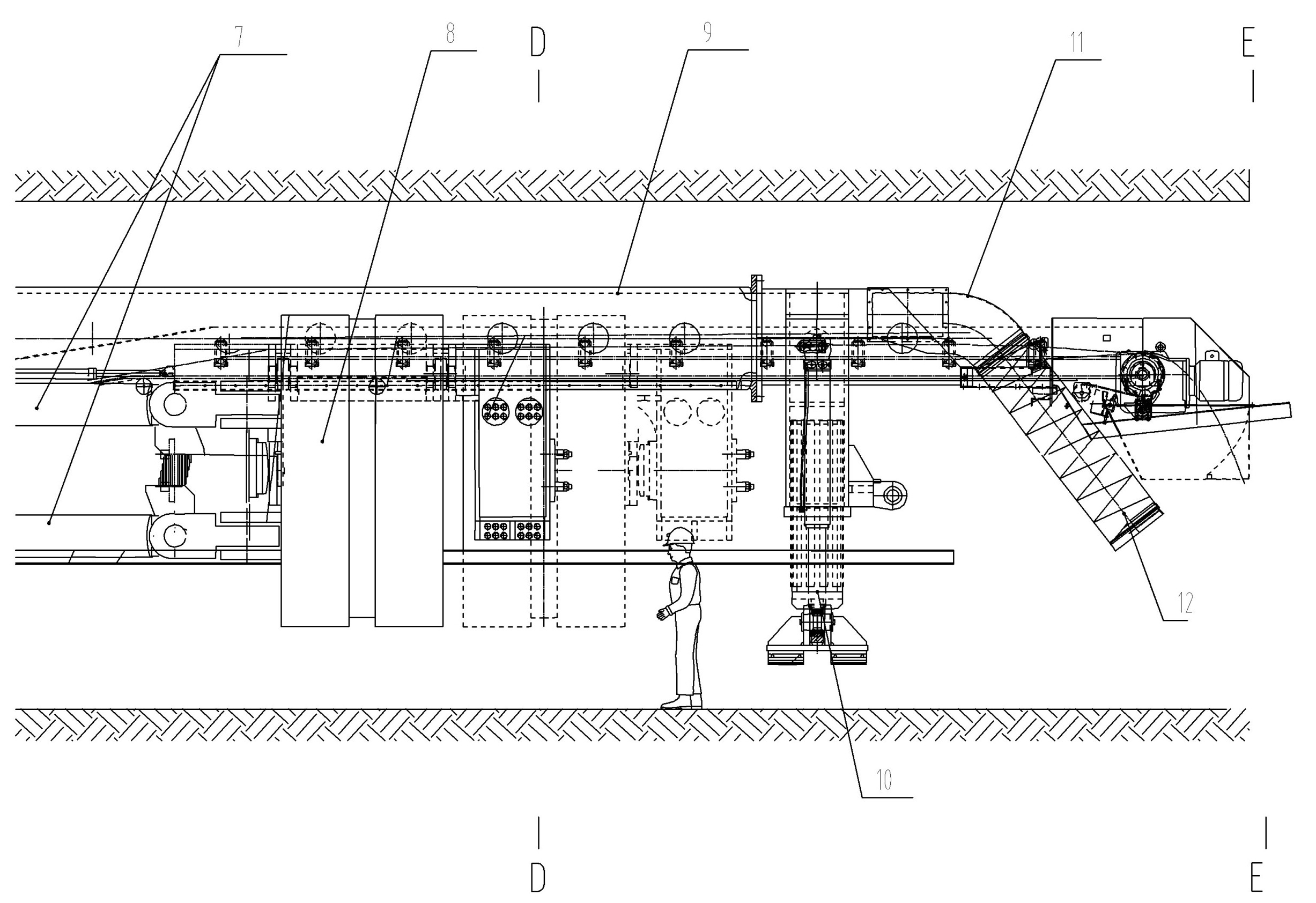

[0024] Embodiment one: see Figure 1-Figure 7 Double circular cutterhead coal roadheader. The roadheader includes a double-circular cutter head tunneling mechanism, a coal and rock conveying device, an anchoring mechanism, a traveling mechanism, etc.

[0025] Wherein, the double-circular cutter head tunneling mechanism includes two annular sub-beams 14 (cylindrical) horizontally arranged inside the machine head, see Figure 4 cross-sectional schematic diagram. The outer sides of the two annular sub-beams 14 are brackets, and four main drive motors 3 (or more) are fixed on the brackets outside each annular sub-beam 14, and the outermost side of the brackets is a shield 2, which is approximately rectangular structure.

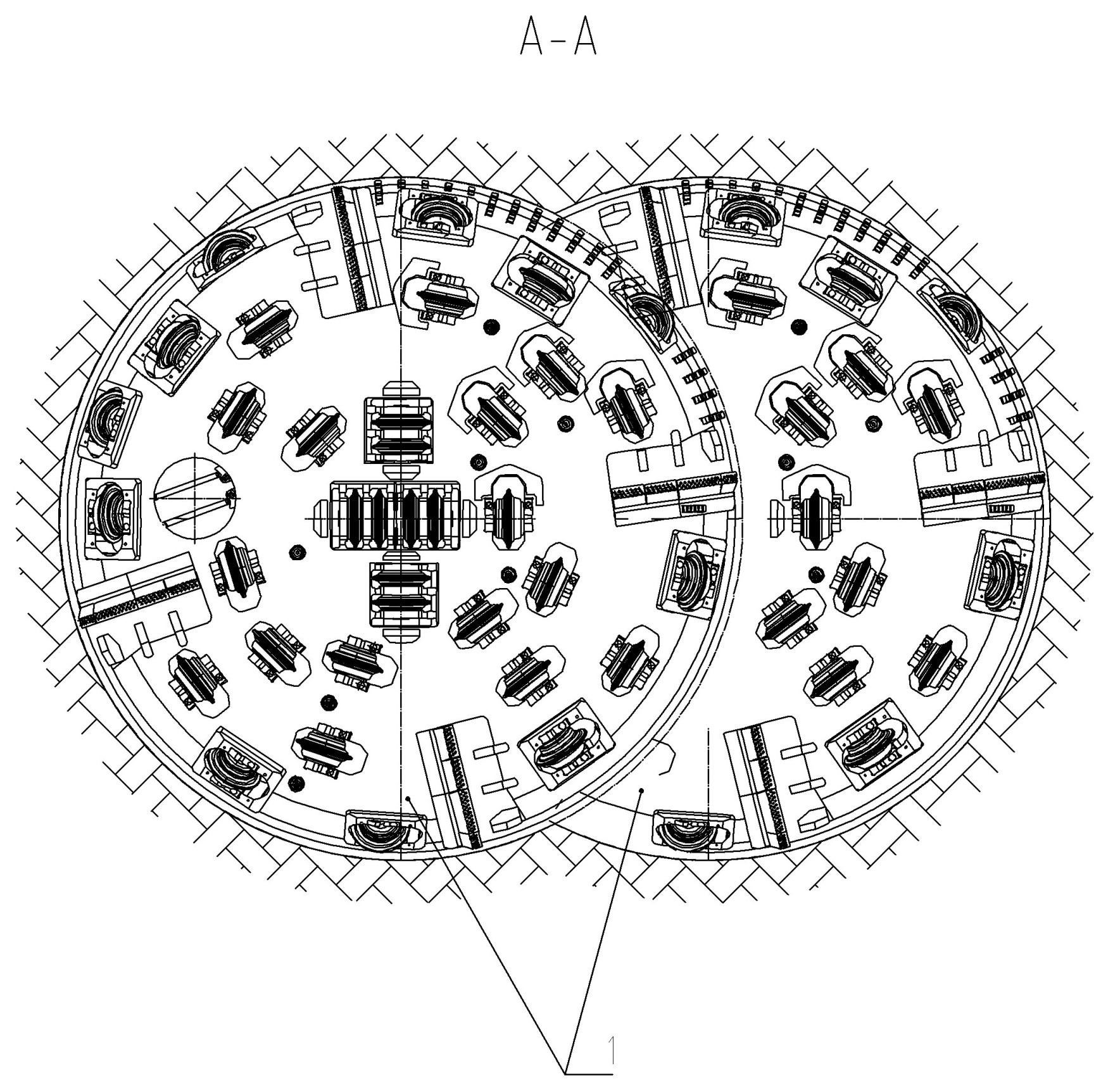

[0026] The front ends of two annular sub-beams 14 are respectively equipped with a circular cutterhead 1, see image 3 , a certain number of hobs are arranged on each circular cutter head 1, and corresponding specifications and quantities of knives can be arr...

Embodiment 2

[0031] Embodiment two: see figure 1 , figure 2 , Figure 6 and Figure 7 , many parts and components of this embodiment have the same number as that of Embodiment 1, and represent the same meaning, so they will not be repeated here. In order to achieve the purpose that the head can be adjusted up and down, in this embodiment, in Figure 6 Torque cylinders 16 are set on the stays 8 in the center, that is, approximately vertical torque cylinders 16 are installed between the two sides of the support body 18 and the stays 8 on both sides respectively, and one end of the torque cylinders is arranged on the stays 8 . One end of the torque cylinder 16 is arranged on the shoe, the shoe cylinder 16 is responsible for the left and right adjustment of the machine head, and the torque cylinder 16 is responsible for the up and down adjustment of the machine head. The cutterhead is realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com