Detection system and method for oxynitride sensor

A technology of nitrogen oxides and detection system, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of fuel consumption, exhaust gas test gas control, lack of nitrogen oxide sensors, etc., and achieve good variability, simple structure, Quick and easy heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

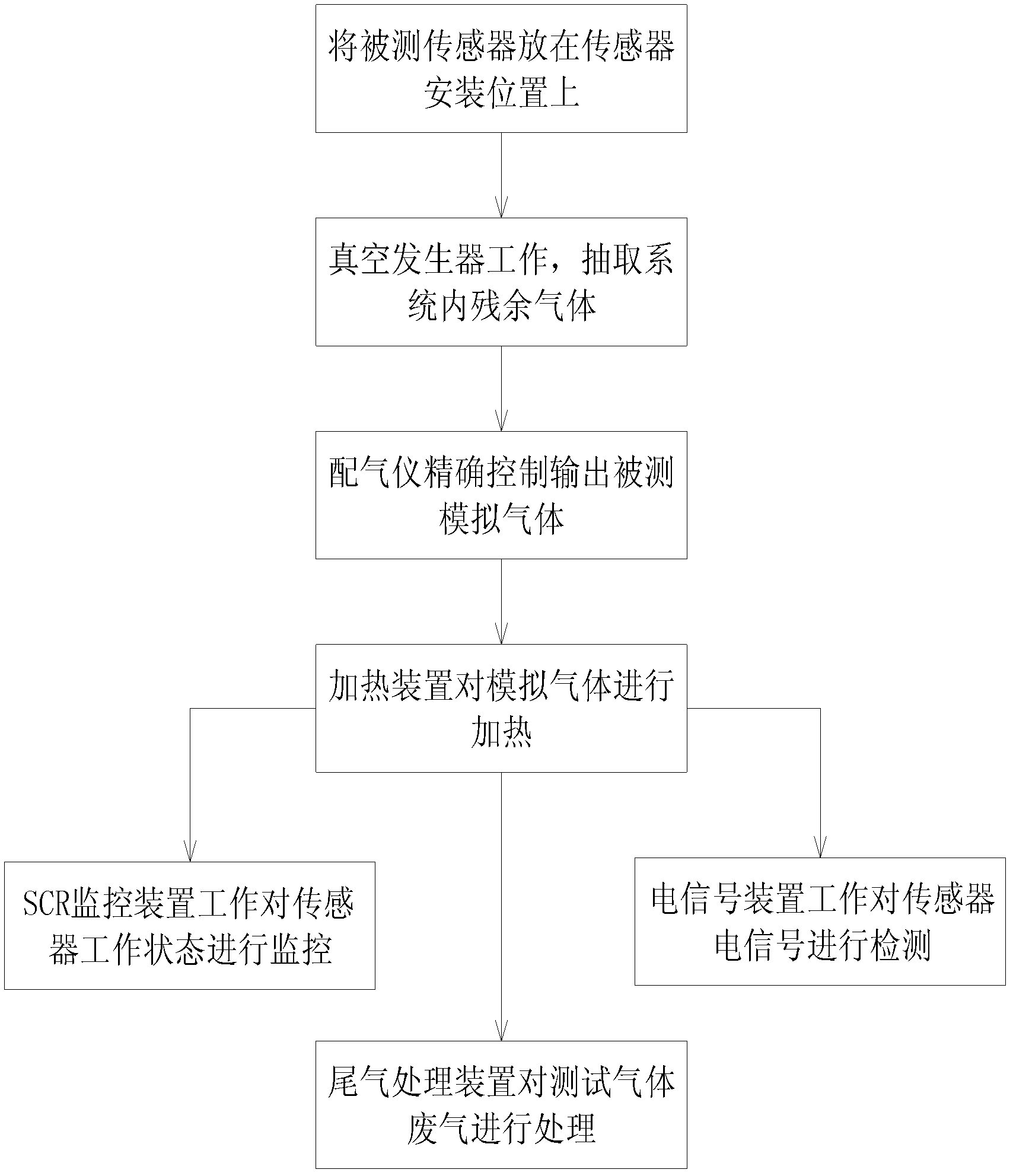

[0034] The technical scheme of the present invention will be further described below in conjunction with the drawings.

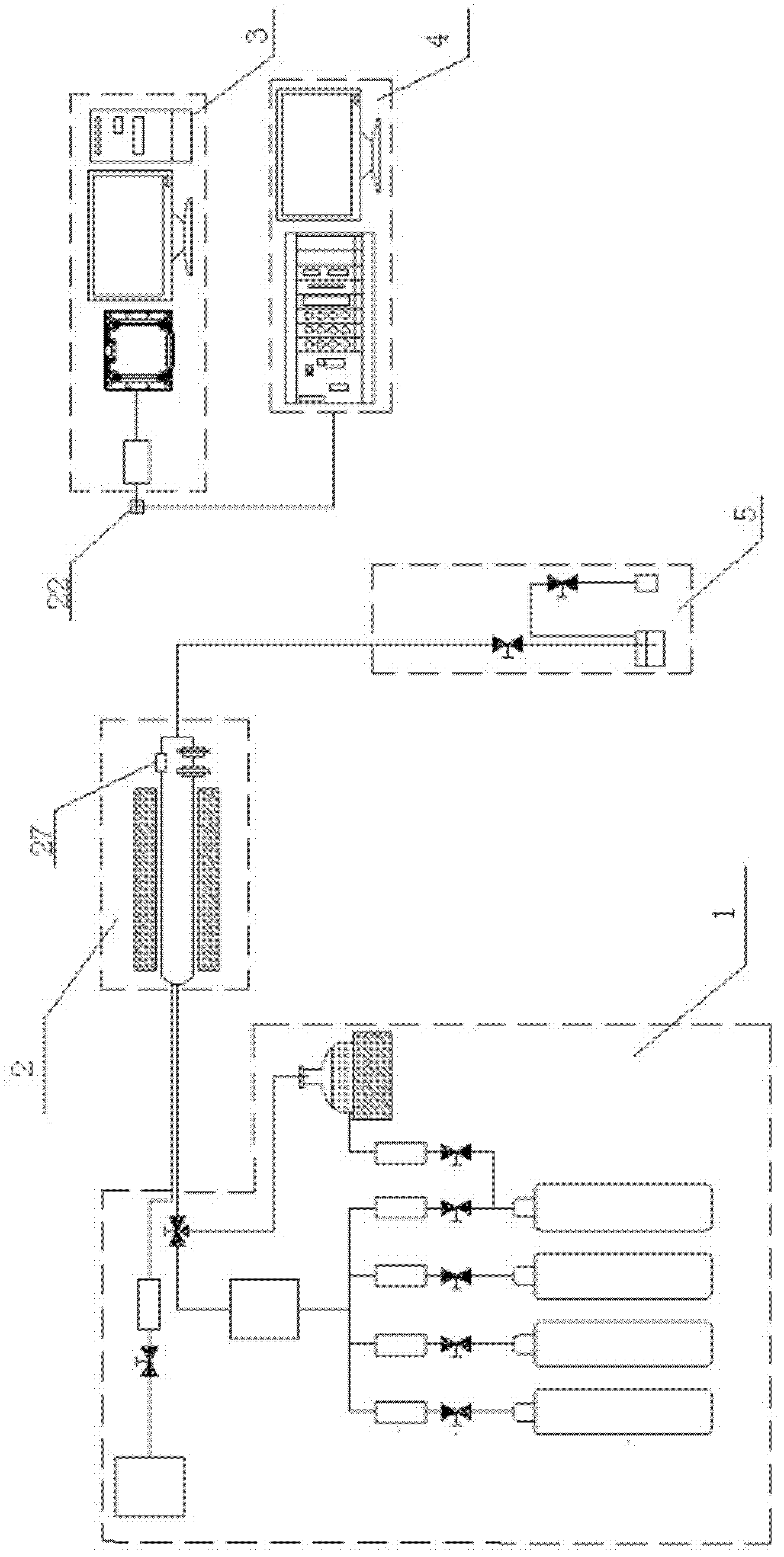

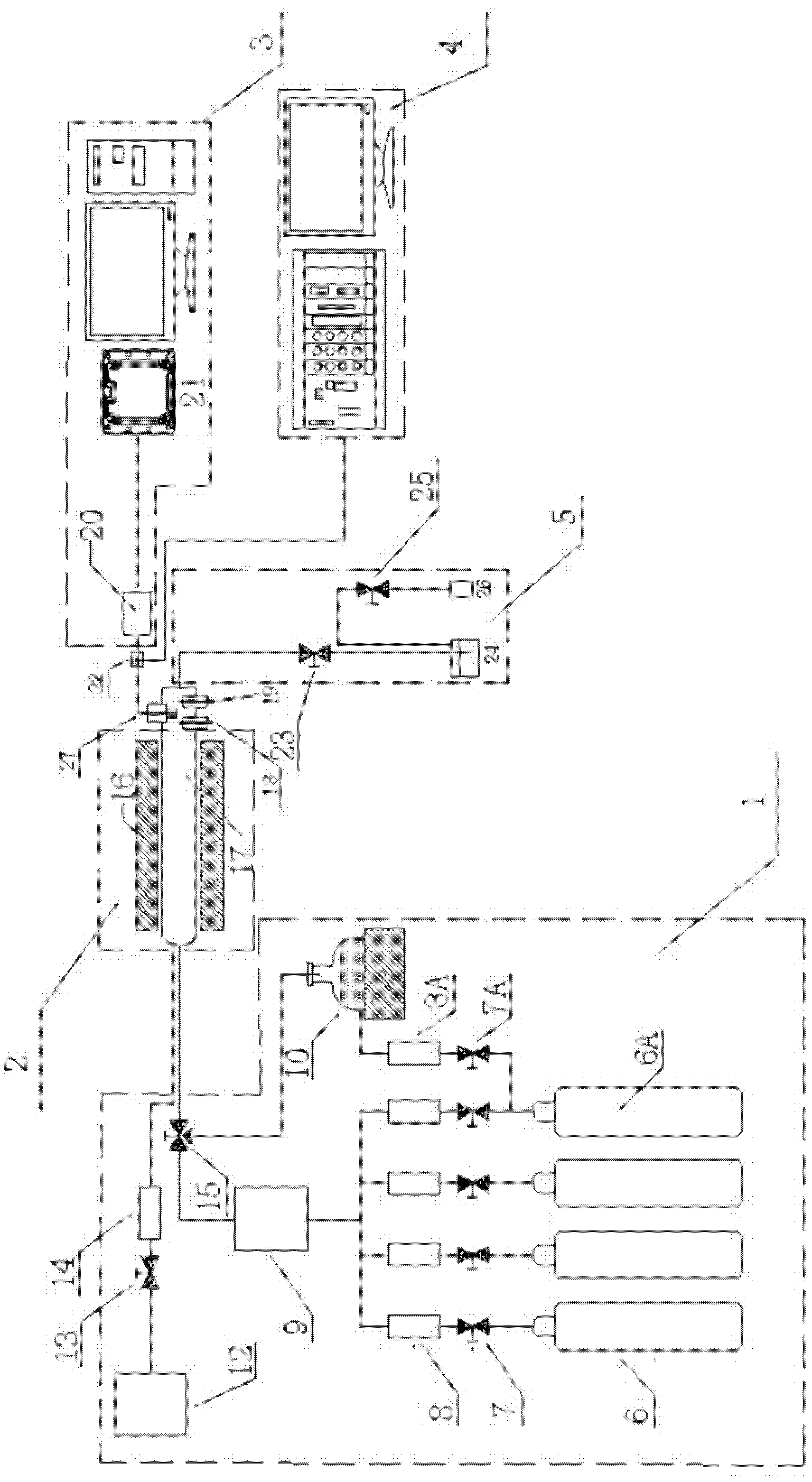

[0035] A nitrogen oxide sensor detection system, which is characterized in that it includes a simulated exhaust gas distribution device 1, a heating device 2, an SCR detection device 3, an electrical signal testing device 4, an exhaust emission processing device 5, a simulated exhaust gas distribution device 1 and a heating device. One end of the device 2 is connected, and the other end of the heating device 2 is connected in parallel with an SCR detection device 3, an electrical signal testing device 4 and an exhaust gas emission processing device 5. The simulated exhaust gas distribution device 1 includes at least two gas storages for storing different simulated exhaust gases Tank 6, one of which is a nitrogen gas storage tank 6A, the gas storage tank 6 is connected to a mass flow meter 8 through a pressure regulating valve 7, a mass flow meter 8 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com