Ultra-low-power organic resistance changing memory device and manufacturing method thereof

A technology of resistive variable memory and ultra-low power consumption, which is applied in the field of ultra-low power organic resistive variable memory devices and its preparation, can solve problems hindering the development and application of organic resistive variable memory, and save preparation time, programming and erasing In addition to the effect of small current and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the present invention is described in further detail by specific embodiment:

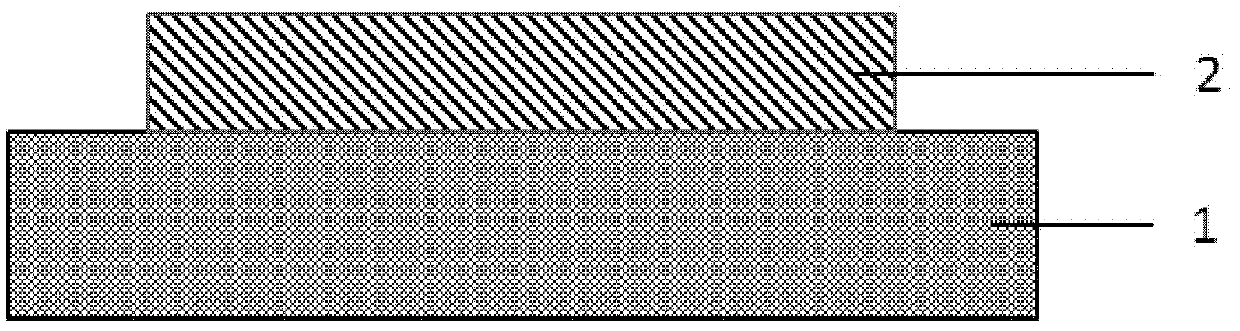

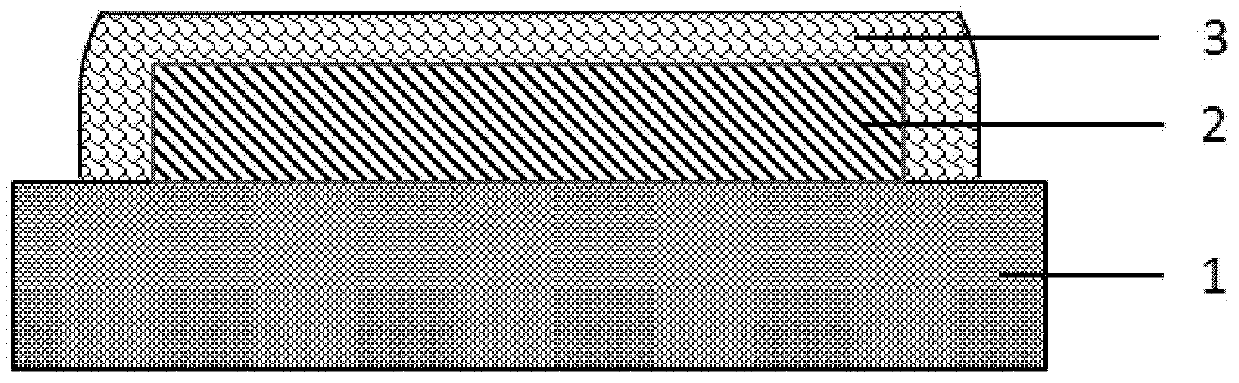

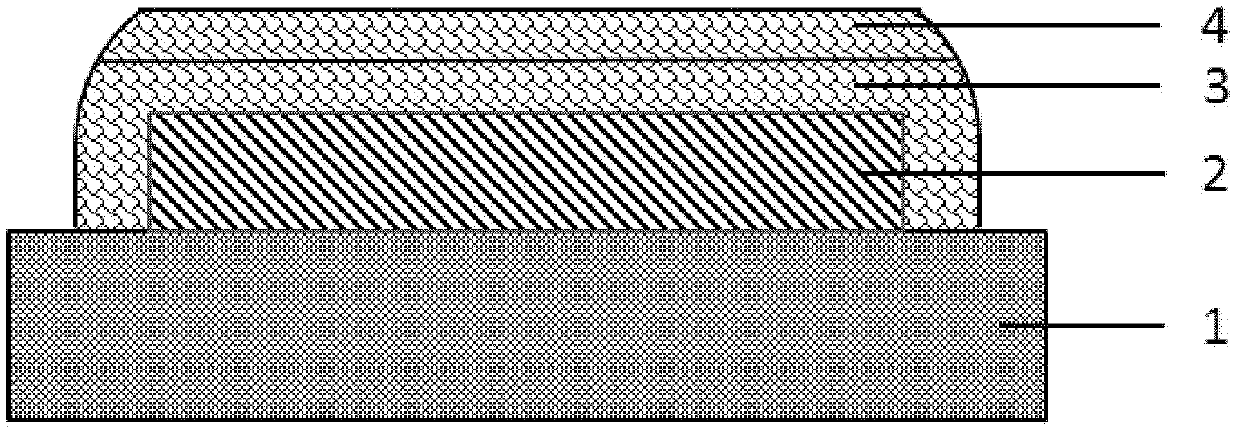

[0025] The process flow of the present invention for preparing ultra-low power organic resistive variable memory is as follows: Figure 1-Figure 5 as shown,

[0026] 1) Utilize physical vapor deposition (PVD) method or other film-forming methods in the integrated circuit (IC) process to form a metal Pt film on the silicon substrate 1, with a thickness between 100nm and 400nm, and use standard photolithography technology to make Its electrodes are patterned to prepare the bottom electrode 2, such as figure 1 shown;

[0027] 2) Utilize Polymer CVD technology to grow the first layer of C-type parylene-C (Parylene-C) film 3, such as figure 2 shown. Then, adopt the same method to deposit one deck of C-type parylene film 4 again on the first layer of C-type parylene, as image 3 shown. Polymer CVD equipment is used for deposition, and the stand...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com