Piezoelectric wafer control type non-contact glue dispensing device

A piezoelectric chip and glue dispensing device technology, which is applied to the surface coating liquid device, embroidery machine mechanism, embroidery machine, etc., can solve the problems of poor consistency of glue points and slow glue dispensing speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

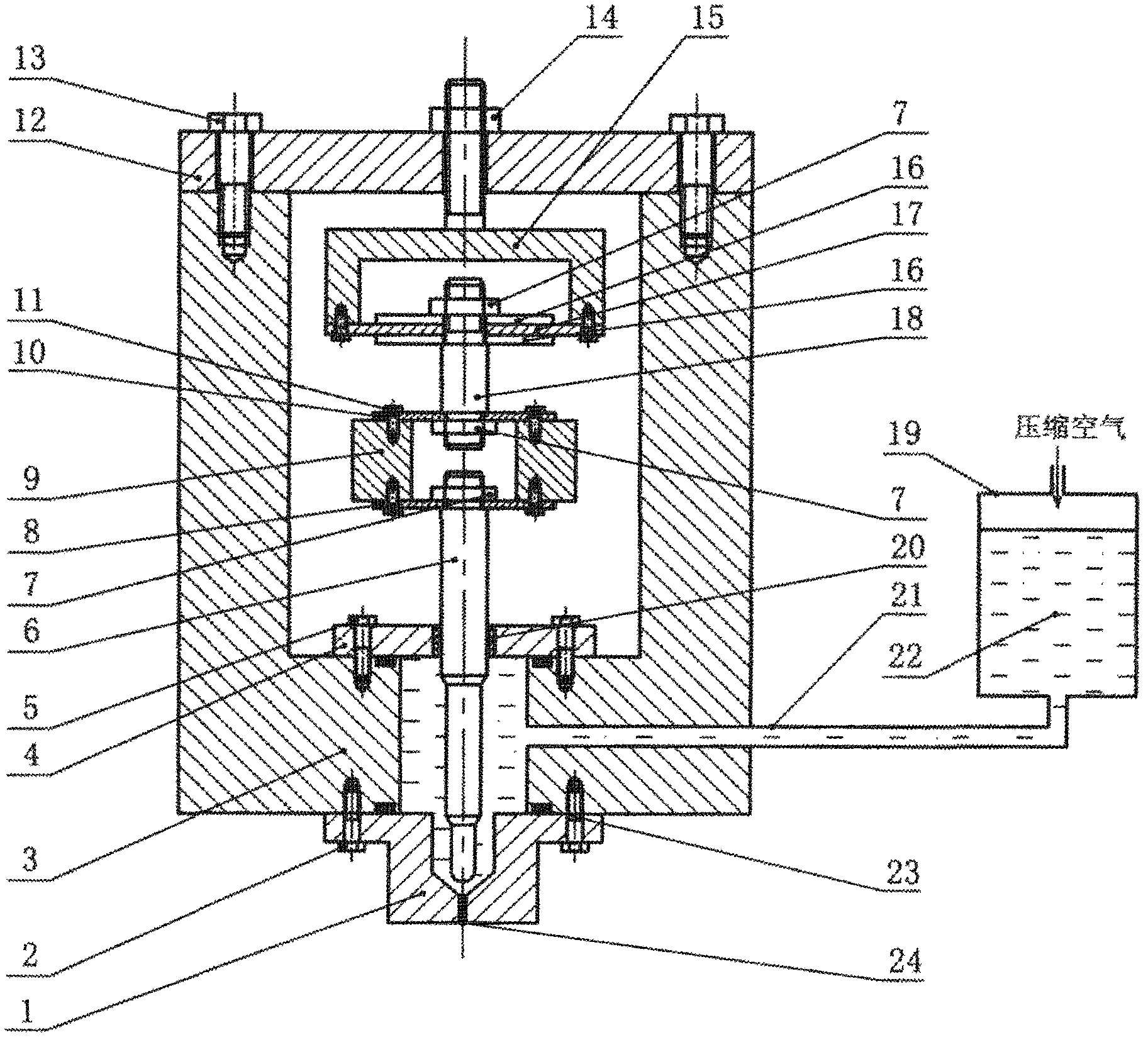

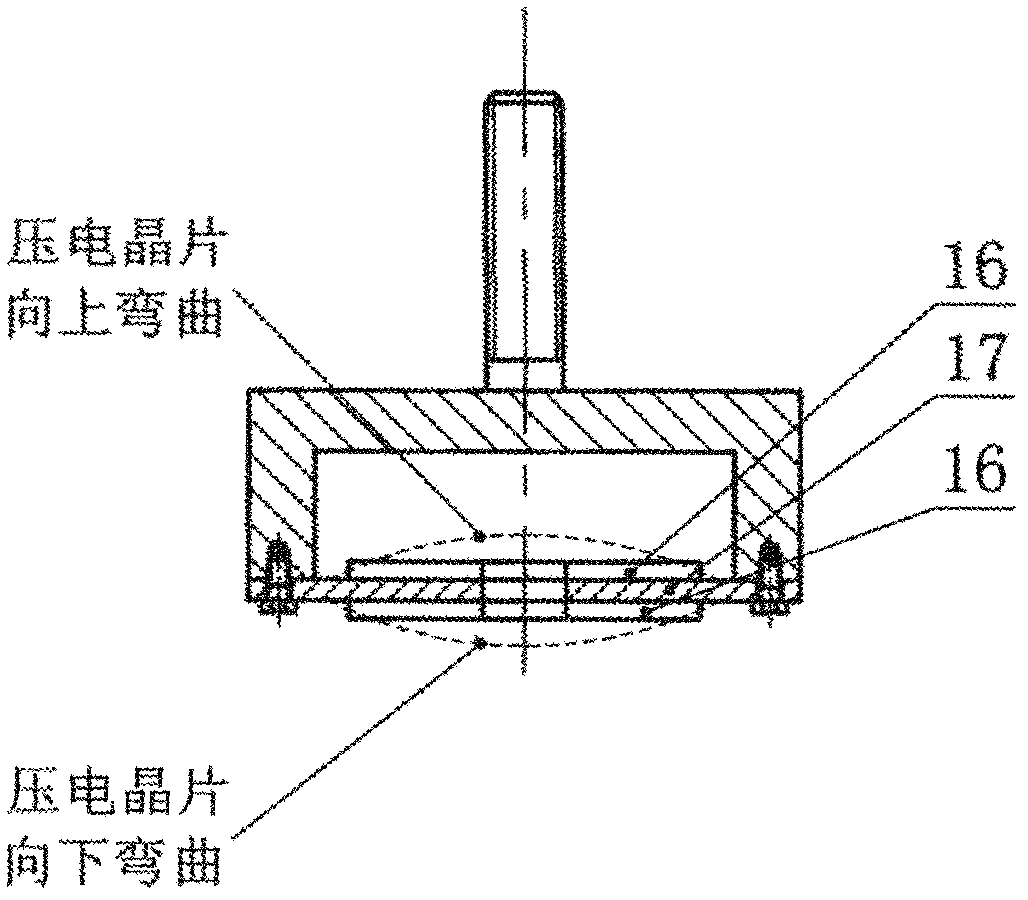

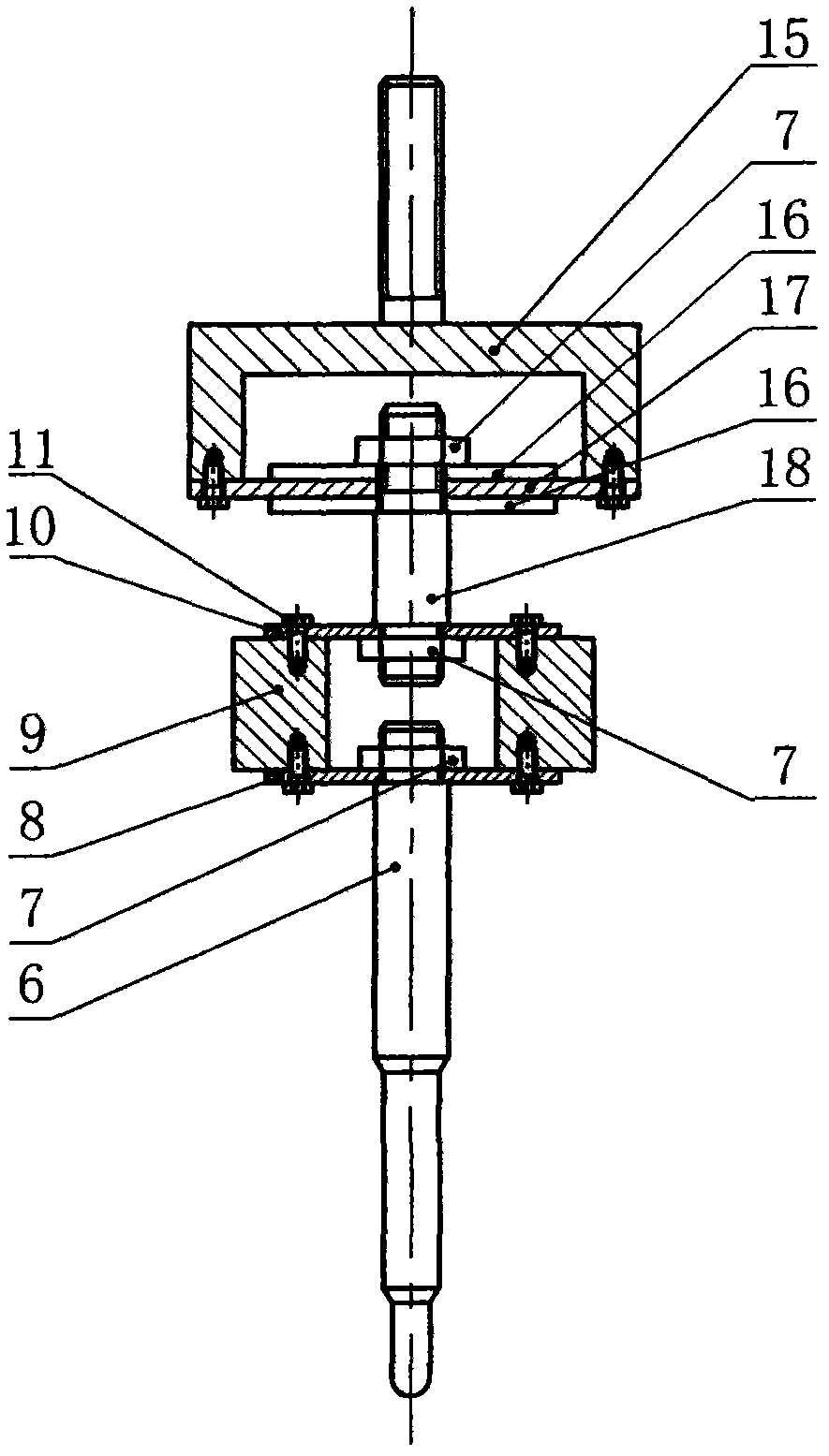

[0030] see figure 1As shown, a piezoelectric chip-controlled non-contact dispensing device of the present invention is composed of the piezoelectric chip displacement amplification mechanism and its auxiliary components shown in FIG. 3 . The piezoelectric chip displacement amplifying mechanism is made of piezoelectric chip (16), substrate (17), end cover (15), transmission vibration rod (18), set nut (7), diaphragm spring 1 (10), mass block ( 9), diaphragm spring II (8), striker (6) form. The piezoelectric wafer (16) is bonded to the base plate (17), and the base plate (17) is fixedly connected to the end cover (15); the two ends of the vibration transmission rod (18) are respectively connected to the piezoelectric wafer (16) and the diaphragm spring 1 ( 10) Fixed connection; the diaphragm spring I (10) is fixedly connected to the mass block (9); the striker (6) is connected to the diaphragm spring II (8), and the diaphragm spring II (8) is fixed to the mass block (9). The n...

Embodiment approach 2

[0036] see Figure 4 As shown, the piezoelectric wafer (16), substrate (17), vibration transmission rod (18), diaphragm spring II (10), mass block (9), diaphragm spring I (8) and connecting rod (31) are composed of The displacement amplifying mechanism amplifies the tiny displacement of the piezoelectric chip, and the connecting rod (31) is connected with the flexible hinge (32). One end of the flexible hinge (32) is fixed on the cavity (3), and the other end is fixedly connected with the striker (6). Through the lever amplification of the flexible hinge (32), when the displacement amplification mechanism moves downward, the striker (6) The displacement is further amplified, which can drive the more viscous glue to realize automatic distribution and realize the injection of glue.

Embodiment approach 3

[0038] see Figure 5 As shown, the piezoelectric wafer (16), substrate (17), vibration transmission rod (18), diaphragm spring II (10), mass block (9), diaphragm spring I (8) and connecting rod (33) are composed of The displacement amplifying mechanism of the horizontal placement, connecting rod (33) is fixedly connected with conversion lever (34), and the middle part of conversion lever (34) is hinged on the cavity (3), and at the other end, conversion lever (34) and striker ( 6) Fixed connection. The micro-displacement of the piezoelectric chip (16) is amplified by the displacement amplifying mechanism, and then through the conversion lever (34), the displacement in the horizontal direction is converted into the displacement in the vertical direction of the striker (6), thereby driving the automatic distribution of the glue liquid and realizing the glue liquid injection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com