Safe cutting machine

A cutting machine and safe technology, applied in the cutting machine field, can solve the problem that the cutting machine is not suitable for cutting standard circular arcs, etc., and achieve the effects of light weight, safe and flexible operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

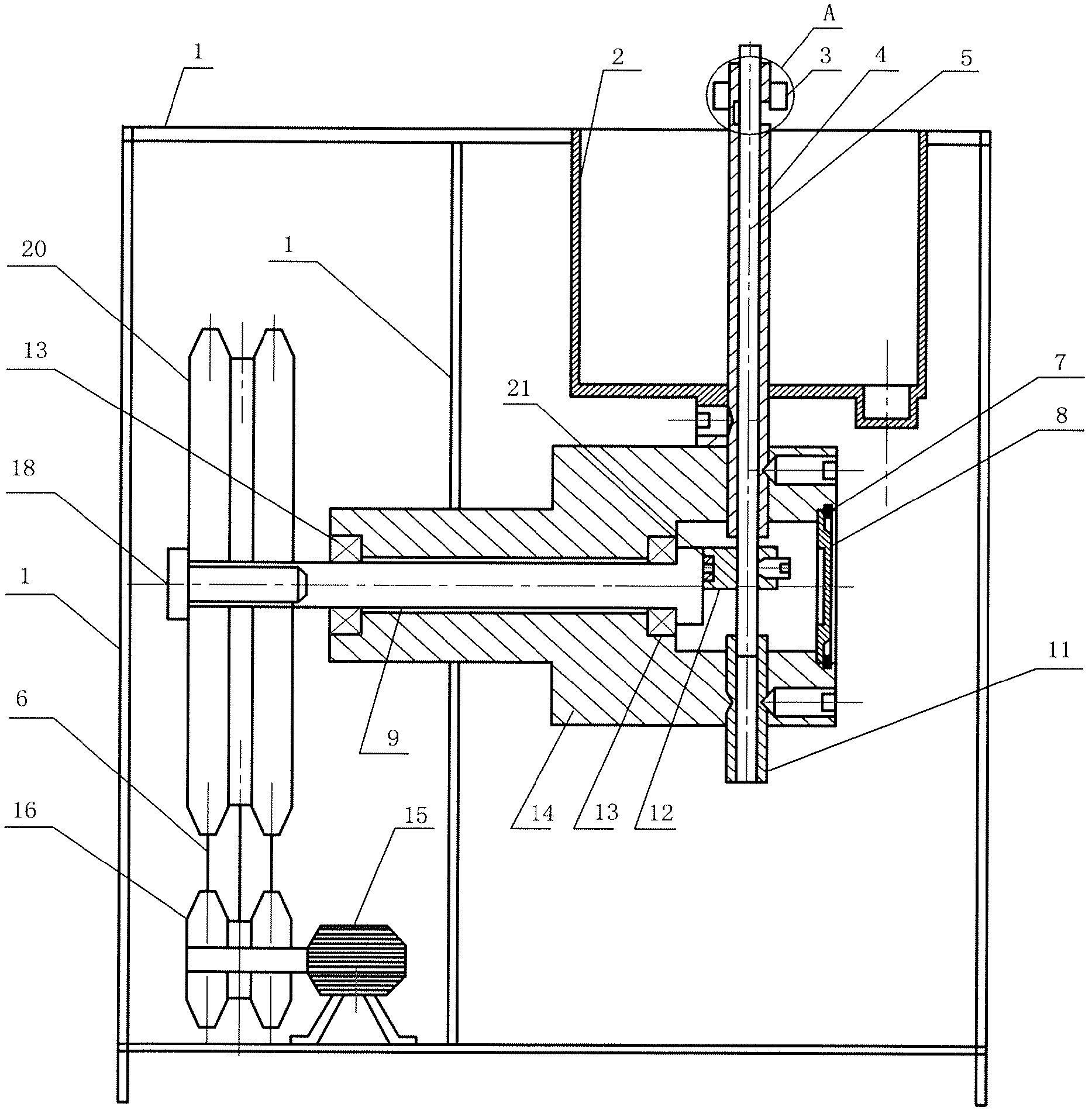

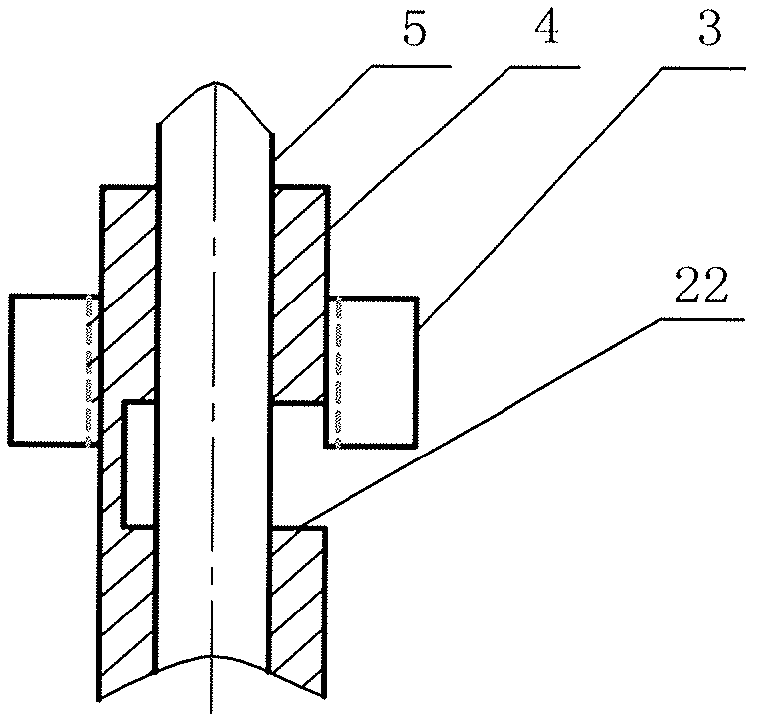

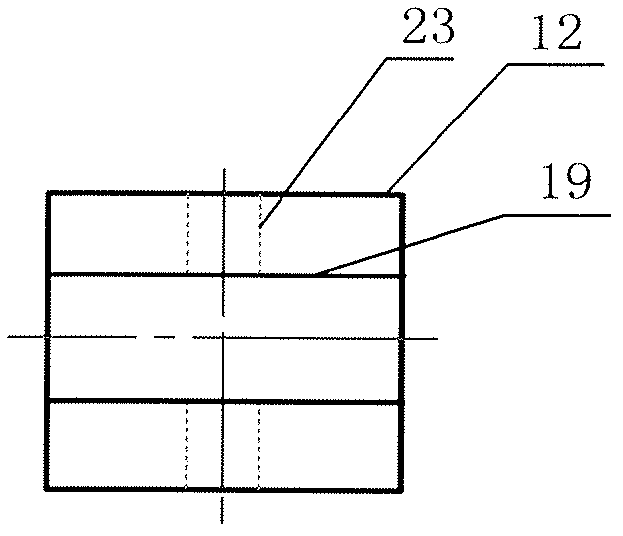

[0023] Such as figure 1 As shown, the safety cutting machine of the present invention includes: a frame 1, a transmission mechanism, a fuselage 14, a shaft 9, a cutter bar 5 and a machine cover 8, and the fuselage 14 is fixed on the frame 1 by screws (not shown) , the shaft 9 is horizontally mounted on the fuselage 14, and a pair of bearings 13 are mounted on the shaft 9, and the bearings 13 are installed in the fuselage 14. One end of the shaft 9 stretches out from the fuselage 14, and the transmission mechanism drives it to rotate. The transmission mechanism includes: a motor 15, a small pulley 16, a large pulley 20 and a belt 6, and the large pulley 20 is fixed on the shaft 9 by a safety screw 18. Belt 6 is contained on small pulley 16 and large pulley 20, and motor 15 is fixed on the frame 1, and motor 15 drives small pulley 16 rotations, and belt 6 drives large pulley 20 rotations, and large pulley 20 drives shaft 9 rotations. The machine cover 8 is fixed on the fuselage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com