Method for adsorbing lead in wastewater by using composite magnetic biological adsorbent

A biosorbent and composite technology, applied in biological water/sewage treatment, adsorption water/sewage treatment, chemical instruments and methods, etc., can solve the problems of reduced treatment efficiency, high cytotoxicity, loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

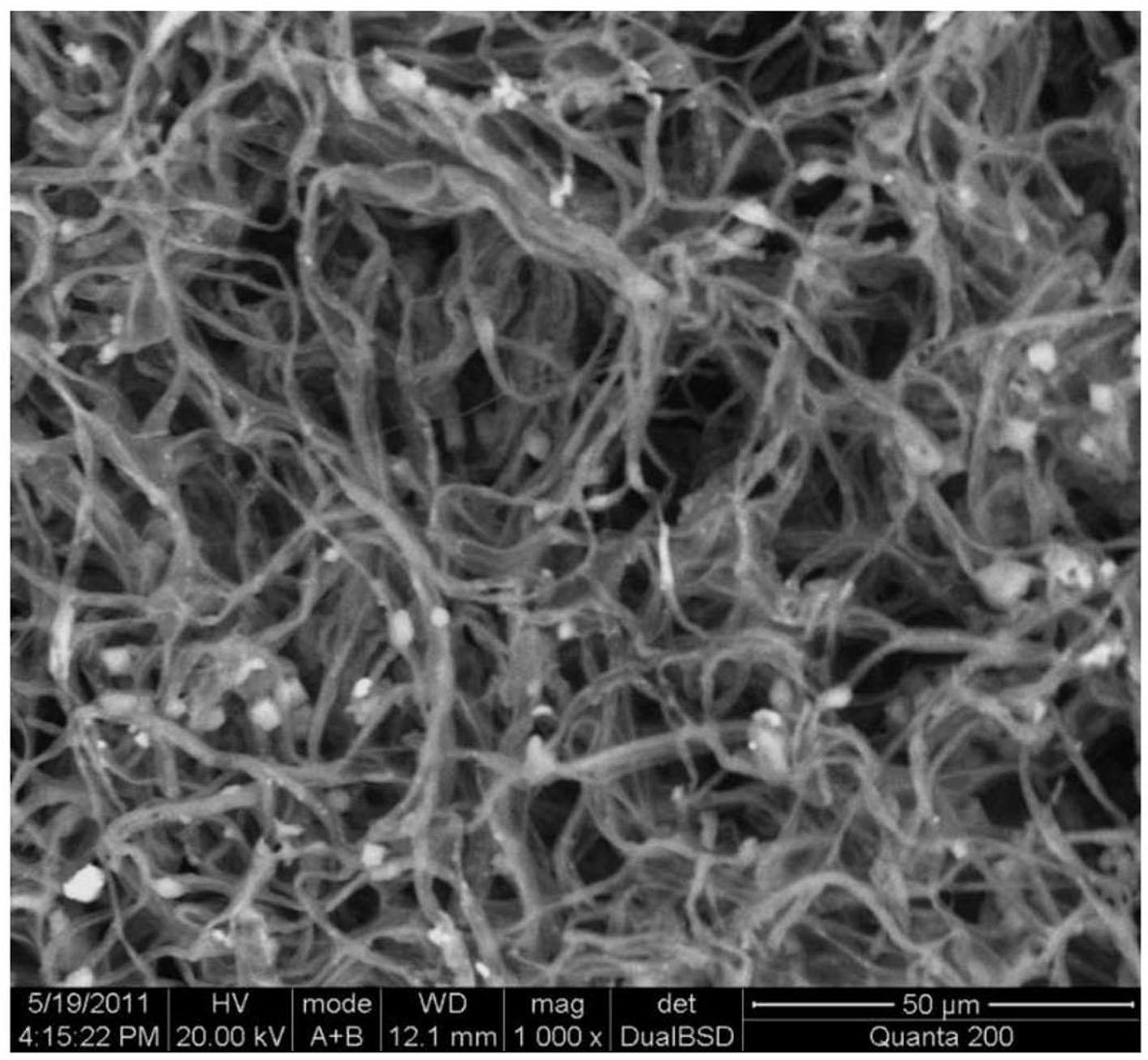

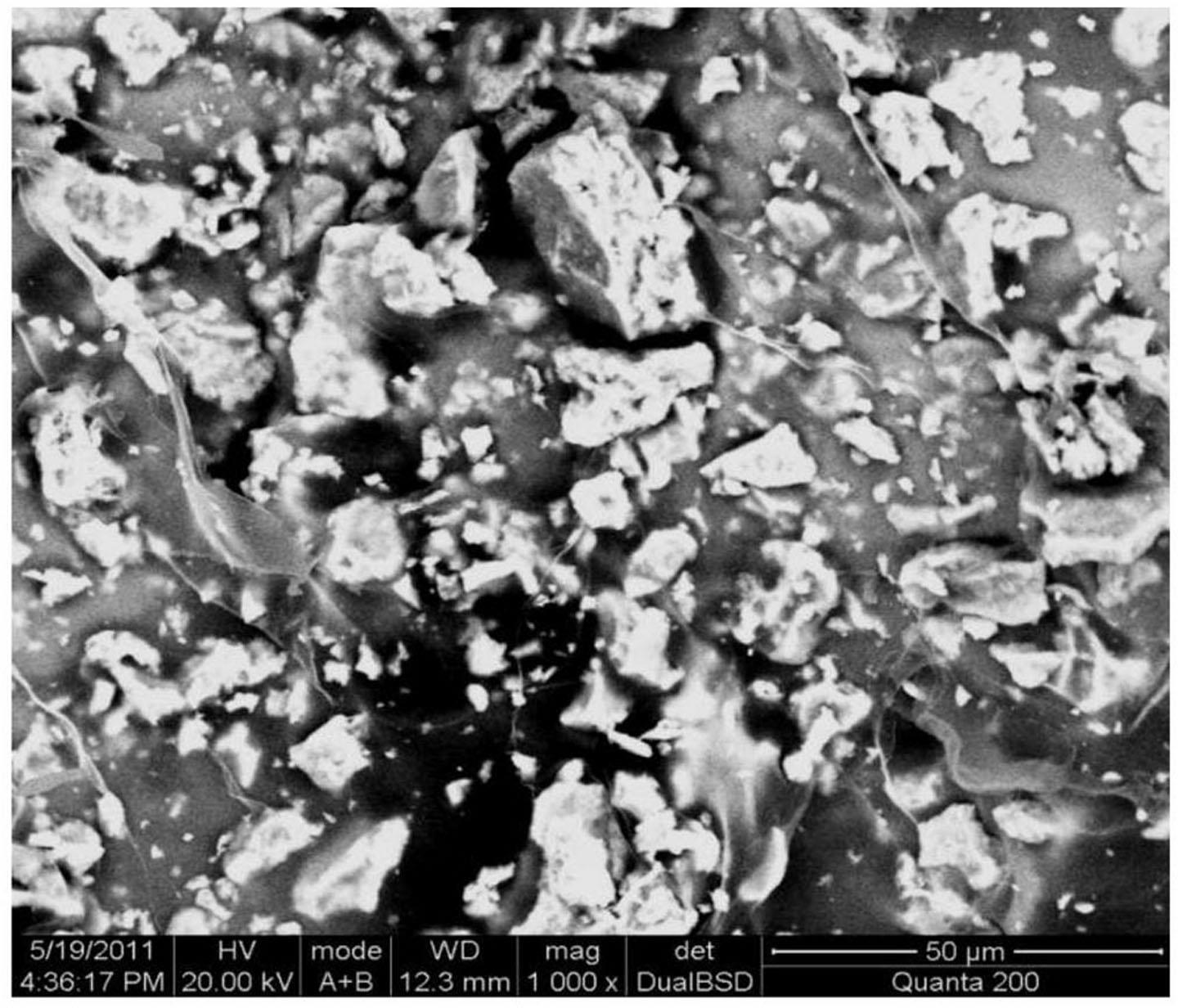

Image

Examples

Embodiment 1

[0038] A method for utilizing a composite magnetic biosorbent to adsorb lead in waste water, comprising the following steps:

[0039] Take 1L of lead-containing industrial wastewater. The Pb(II) content of the wastewater is about 300mg / L. Heavy) The compound magnetic biosorbent of the present invention, under the condition of temperature of 35°C (30°C to 35°C is acceptable) and rotation speed of 150 rpm, oscillating and adsorbing for 8h, and then directly filtering to separate the water and the adsorbed compound Magnetic biosorbent, the lead-containing industrial wastewater filtered out after separation is adjusted to be neutral and then discharged to complete the treatment of lead-containing industrial wastewater.

[0040] The unadsorbed lead was determined by flame atomic absorption spectrophotometry, and the lead removal rate reached 89.24% (see the comparison of lead removal effects in Table 4 below). The used biosorbent can be recycled through analysis. The specific opera...

Embodiment 2

[0049]The composite magnetic biosorbent prepared in Example 1 was added to lead-containing industrial wastewater (Pb(II) concentration 10-500 mg / L) at different concentrations at 60 g / L (wet weight), the lead-containing industrial wastewater The pH value of each was adjusted to 5, and the adsorption was oscillating at 35°C and 150 rpm. After being adsorbed for 8 hours, it was directly filtered to separate the composite magnetic biosorbent from the lead-containing industrial wastewater. The filtered lead-containing industrial wastewater Emissions after adjusting to neutral.

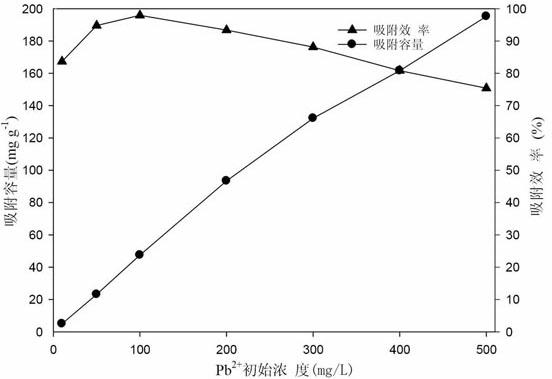

[0050] The unadsorbed lead ions in the solution were measured by flame atomic absorption spectrophotometer, and the adsorption effect of the composite magnetic biosorbent on lead in wastewater containing lead with different concentrations image 3 shown. Depend on image 3 Visible, the method of the present invention reaches 90.18% to the removal efficiency of the lead-containing waste water of 10 mg / L, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com